Evaporation pipe type miniature-small-sized engine combustion chamber

A combustion chamber and evaporation tube technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of low combustion efficiency in combustion chambers, long flames, and low evaporation rate of evaporation tubes, and achieve improved combustion efficiency and oil and gas distribution Uniform, improved evaporation rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

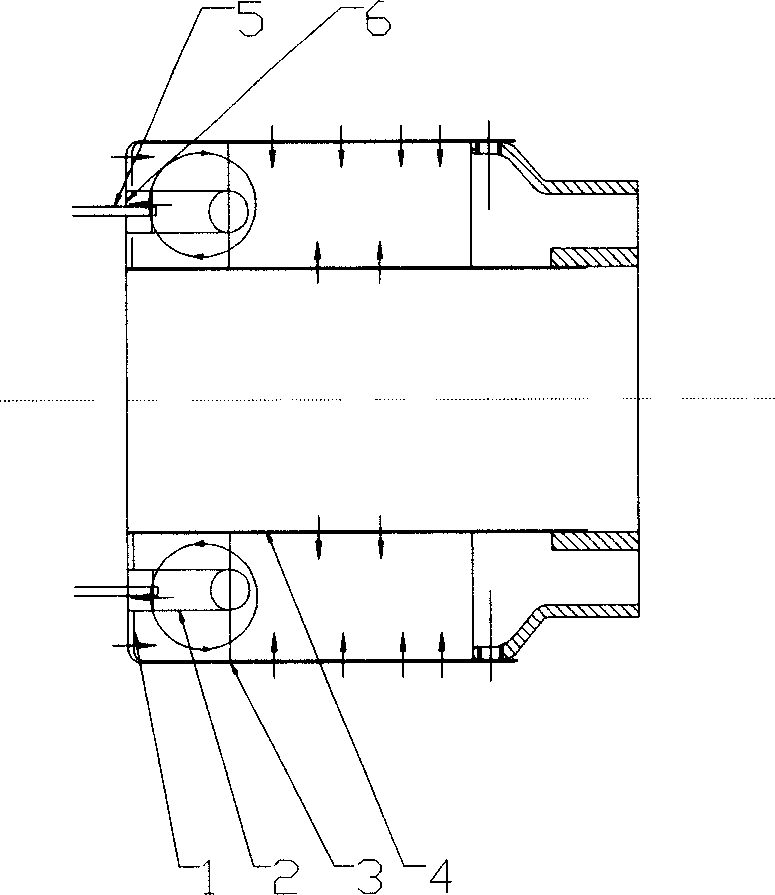

[0021] Such as figure 2 , 3 As shown, the present invention is composed of the inner wall 4 and the outer wall 3 of the combustion chamber flame tube, 3-12 T-shaped evaporation tubes 2, and fuel nozzles 5. Evenly arranged, 3-12 fuel nozzles 5 are inserted into 3-12 T-shaped evaporation tubes in the radial direction, and a plurality of holes 6 are punched on the inner wall 4, outer wall 3 and front end wall 1 of the combustion chamber flame tube, the number of holes and The aperture is determined by the gas volume distribution of the combustion chamber and the circumferential size of the flame cylinder in the combustion chamber. If a position with a large volume is required, the aperture is relatively large, and the size is determined by the circumference of the flame cylinder. How big and how much can be drilled. The ratio of the sum of the hole area to the total opening area should be consistent with the gas volume distribution at this place, and the general quantity is sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com