Engine frame

A technology for engine mounts and engines, which can be used in power units, mechanical equipment, springs made of plastic materials, etc., and can solve problems such as lack of rubber elastomers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

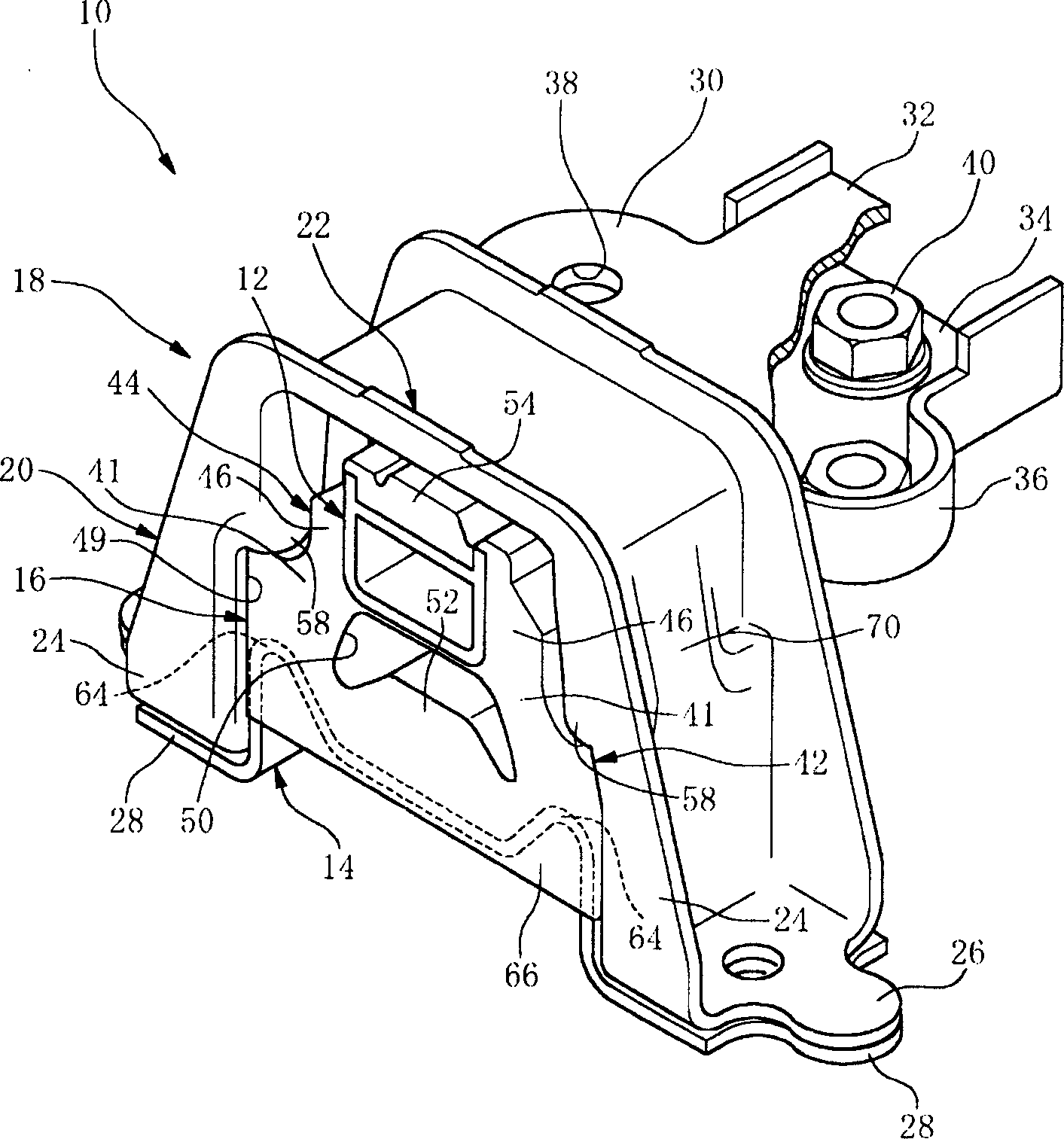

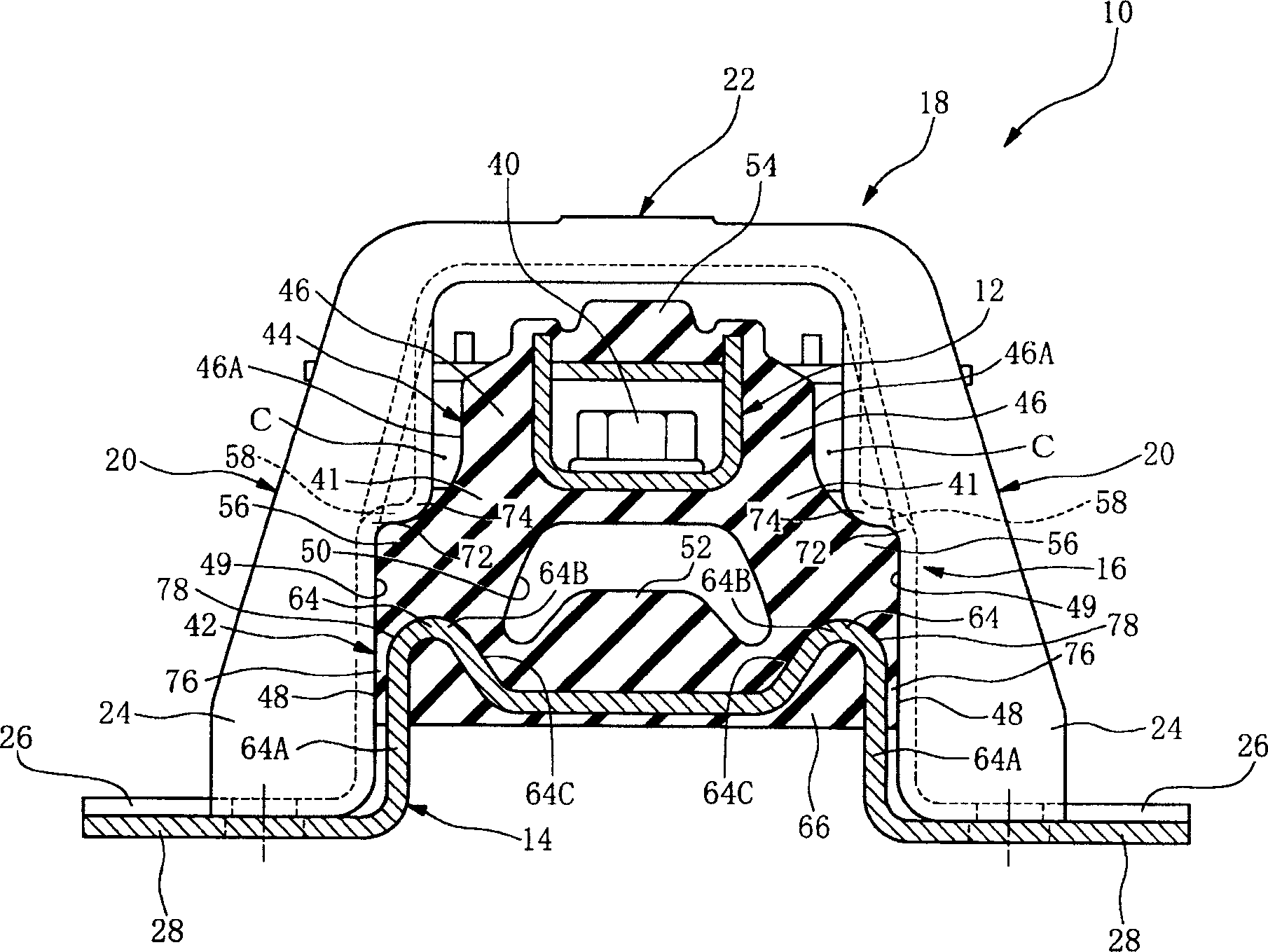

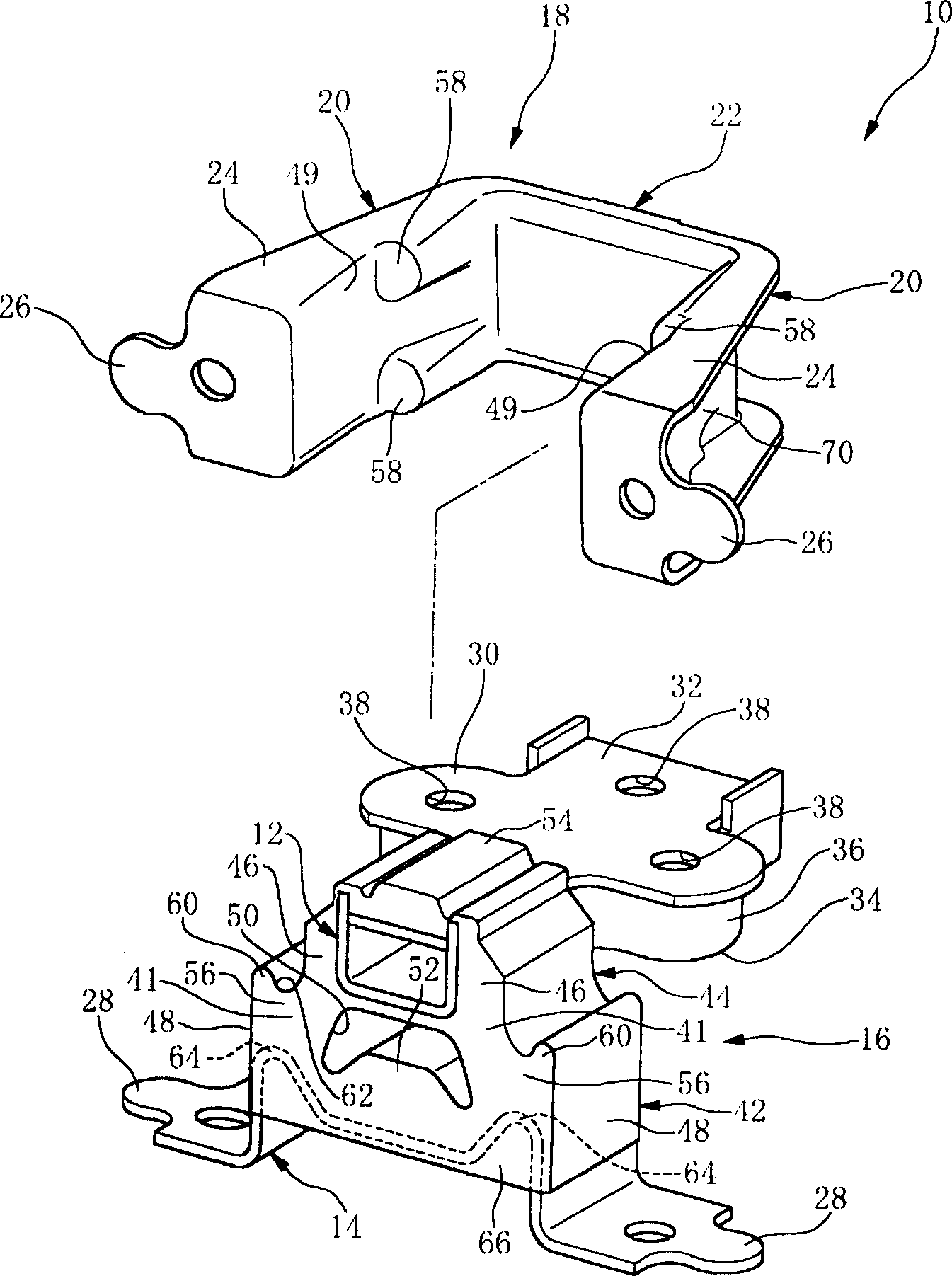

[0050] Embodiments of the invention will be described in detail below with reference to the drawings. exist figure 1 , 3 In and 4, 10 represents an engine mount for a vehicle according to an embodiment, which includes an upper metal element (upper rigid element) 12 fixed on the engine side, and a lower metal element (lower rigid element) 14 fixed on the vehicle body side , a rubber elastic body 16 connecting them together, and a bridge-shaped stop metal member (rigid stop member) 18 constituting a separation from the above-mentioned elements. The rubber elastic body 16 is integrally bonded to the upper and lower metal elements 12, 14 by vulcanization during its vulcanization molding process.

[0051] The bridge-shaped stop metal member 18 has a pair of front and rear strut portions 20 and a bridge portion 22 connecting the pair of strut portions 20 in the vehicle front-rear direction. Such as figure 1 and 3 As shown, the stop metal element 18 is in the left and right di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com