Annealing treatment method of crystal in neutral and inert atmosphere

A technology of annealing treatment and inert atmosphere, which is applied in the field of crystal annealing method and heat treatment, can solve the problems of unsatisfactory transparency, ion valence state change, and affecting crystal performance, so as to improve crystal integrity and optical uniformity, with good effect and Good recrystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Three pieces of sapphire crystal blanks grown by guided temperature gradient method are placed in the heat treatment chamber of the "crystal annealing device". After the annealing device is sealed, the gas in the annealing device (annealing furnace) is exhausted to a vacuum degree higher than 3×10 -3 Pa, filled with high-purity argon, decarburized and decolorized, recrystallized and annealed at high temperature in an inert atmosphere. The annealing program is heating rate: 90°C / hour-110°C / hour; constant temperature at 1830°C for 96 hours; cooling rate: 90°C / hour-110°C / hour.

[0016] Evaluation of crystal detection level before annealing: the first crystal has a slight filamentous optical path and internal filaments (B501 grade); the second crystal has obvious filamentous optical paths and internal white filaments (B901 grade); the third There are obvious filamentary light paths and filaments (B912 grade) inside the fast crystal (the whole).

[0017] Afte...

Embodiment 2

[0018] Embodiment 2: five pieces of sapphire crystal blanks grown by guided temperature gradient method are placed in the heat treatment chamber of the "crystal annealing device". After the annealing device is sealed, the gas in the annealing device (annealing furnace) is exhausted until the vacuum degree is higher than 3×10 -3 Pa, filled with high-purity hydrogen, decarburized and decolorized, recrystallized and annealed at high temperature in a reducing atmosphere. The annealing procedure is the same as that of Example 1: heating rate: 90°C / hour-110°C / hour; constant temperature at 1830°C for 96 hours; cooling rate: 90°C / hour-110°C / hour.

[0019] Evaluation of crystal detection grade before annealing: the first crystal is B661 grade; the second fast crystal is B900 grade; the third fast crystal is B012 grade; the fourth fast crystal is B810 grade; the fifth fast crystal is B431 grade.

[0020] After high-temperature annealing in a reducing atmosphere (hydrogen), the inspecti...

Embodiment 3

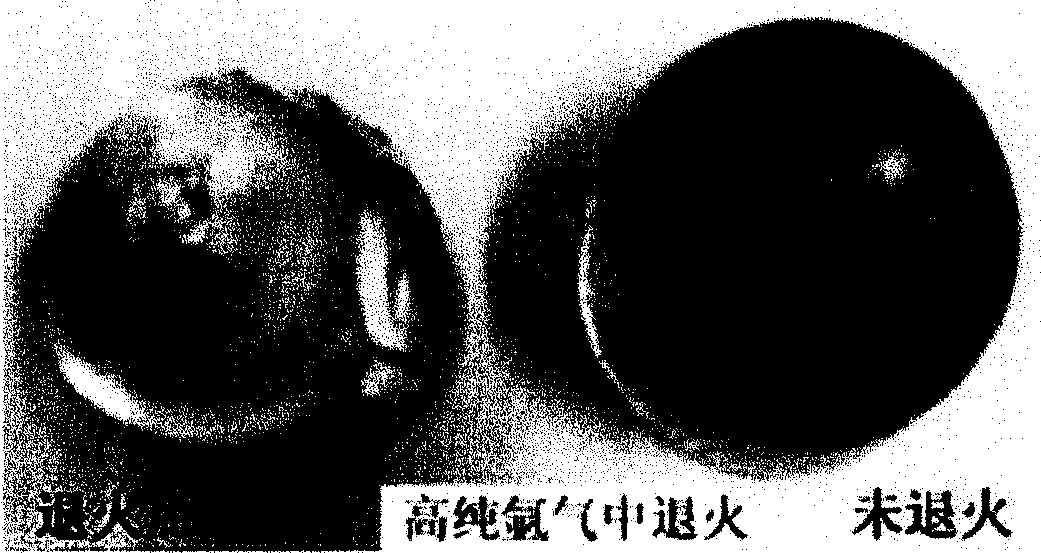

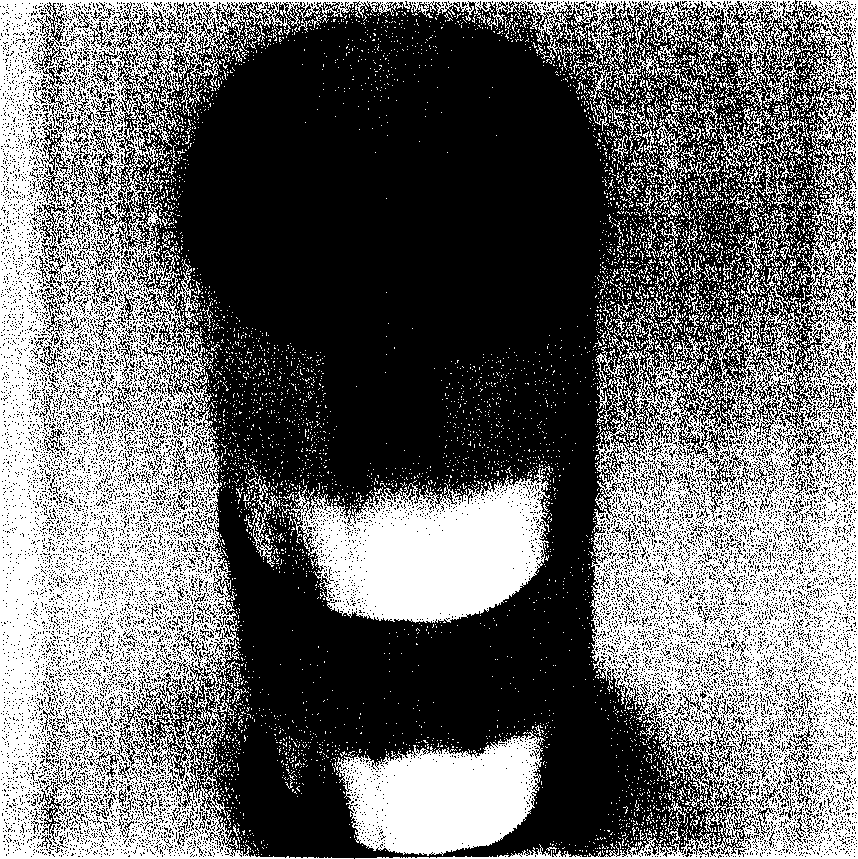

[0027] Embodiment 3: the decarburization and decolorization of 2 inch cylinders in diameter, the annealing of color center, the sapphire crystal blank that guides temperature gradient method growth, is processed into 2 inch cylinders in diameter ( figure 2 ), placed in the heat treatment chamber of the "crystal annealing device", after the annealing device is sealed, exhaust the gas in the annealing device (annealing furnace) to a vacuum degree higher than 3×10 -3 Pa, fill high-purity nitrogen into the furnace to make the pressure in the furnace greater than the atmospheric pressure, start to heat up, when the furnace temperature rises to about 900°C, start to deflate, and maintain the pressure in the furnace at 0.03-0.05MPa. The annealing program is heating rate: 215°C / hour-310°C / hour; constant temperature at 1740°C for 5 hours; cooling rate: 215°C / hour-305°C / hour. After being annealed in a neutral atmosphere (nitrogen), the sapphire cylinder becomes a crystal clear colorles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com