Coated wire with flexible coating

A technology of flexible coating and cored wire, applied in the field of flexible coating cored wire and cored wire, can solve the problems of low effective utilization rate of treatment package, large amount of magnesium and air combustion, air pollution, etc., to solve the problem of cleanliness Production problems, reducing the amount of magnesium added, and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

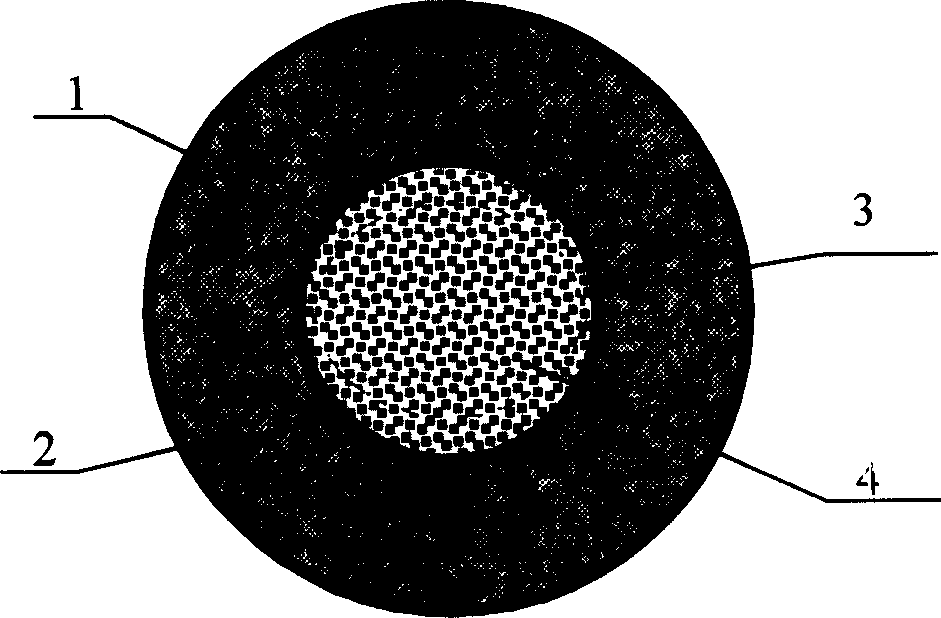

[0023] With reference to accompanying drawing, the present invention comprises steel belt 1, the powder material layer 2 that is wrapped in the steel belt 1 and the core wire 4 that is located in the powder material layer 2, is coated with one deck by asphalt as binding agent at the surface of core wire 4 flexible coating3.

[0024] The following is a comparison with application examples:

[0025] 1. Comparing flexible coated cored wire with uncoated magnesium cored wire, wire cored wire and bunched magnesium cored wire, the comparative advantage in terms of magnesium efficiency:

[0026] The weight of the treated molten iron: 1000kg / bag, the height of the molten iron: 650mm, the temperature of the treated molten iron: 1460°C, and the sulfur content of the original molten iron: 0.025%.

[0027]

Types of cored wire

Unit length includes

Magnesium content g / m

Core diameter

mm

Feeding speed

m / min

Unit time plus

Magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com