Super active carbon preparation method

A kind of activated carbon and super technology, which is applied in the field of chemical production, can solve the problems of poor adsorption performance of activated carbon and long process time, and achieve the effect of compact internal structure, high stacking density and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

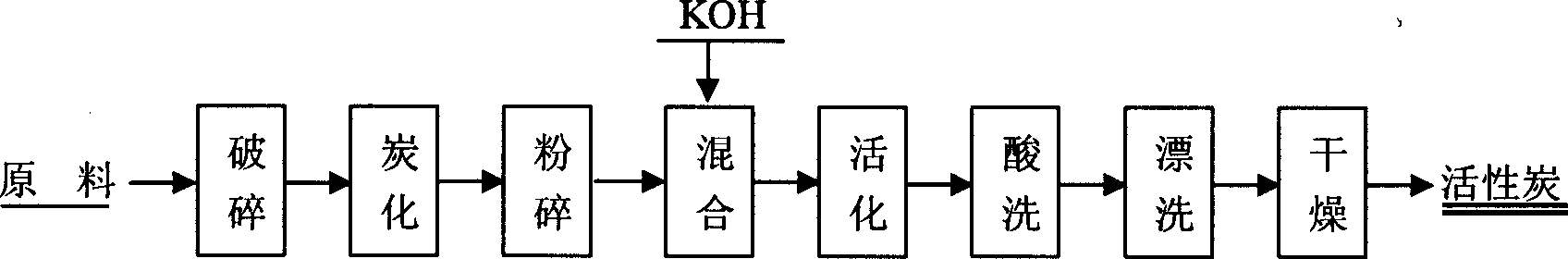

Method used

Image

Examples

Embodiment 1

[0023] Crush coconut shells and walnut shells to 2-3 mm, and carbonize them at a microwave power of 700W and a carbonization temperature of 600C for 10 minutes to obtain coconut shell carbonized materials. Grind the prepared carbonized materials to 71 μm and mix with KOH solid according to the mass of carbonized materials / potassium hydroxide After fully mixing at a ratio of 1:3, put it in a microwave oven, activate it at a microwave power of 700W and an activation temperature of 700°C for 25 minutes, pass nitrogen gas on the surface of the material layer during the activation process, and pickle it 3 times with hydrochloric acid with a concentration of 3% by weight Finally, rinse with distilled water until the pH value reaches 6.0, and dry at a temperature of 120°C for 2 hours to obtain the finished activated carbon.

[0024] The test conditions and test results are shown in Table 1:

[0025] Test conditions

Embodiment 2

[0027] Broken the coconut shell to 3-5mm, carbonized at 700W of microwave power and carbonization temperature of 600C for 10min to obtain the coconut shell carbonized material, pulverized the prepared carbonized material to 120 μm and KOH solid according to the carbonized material / potassium hydroxide mass ratio of 1: 6 After fully mixing, put it in a microwave oven and activate it for 15 minutes at a microwave power of 1400W and an activation temperature of 750°C. During the activation process, pass nitrogen gas on the surface of the material layer, pickle with hydrochloric acid with a concentration of 3% by weight for 5 times, and then rinse with distilled water to pH value to 5.5, dried at a temperature of 120° C. for 3 hours to obtain finished activated carbon.

[0028] The test conditions and test results are shown in Table 2:

[0029] Test conditions

[0030] Example 3

[0031] Crush walnut shells to 2-3mm, carbonize at 700W microwave power and carbonization t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com