High temperature resistant magnetic carrier, its preparation process and application

A magnetic carrier and high-temperature-resistant technology, which is applied in the direction of catalyst carrier, inorganic material magnetism, chemical instruments and methods, etc., can solve the problems of easy loss of magnetism, and achieve the effect of complete coverage, uniform thickness, and uniform carrier particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

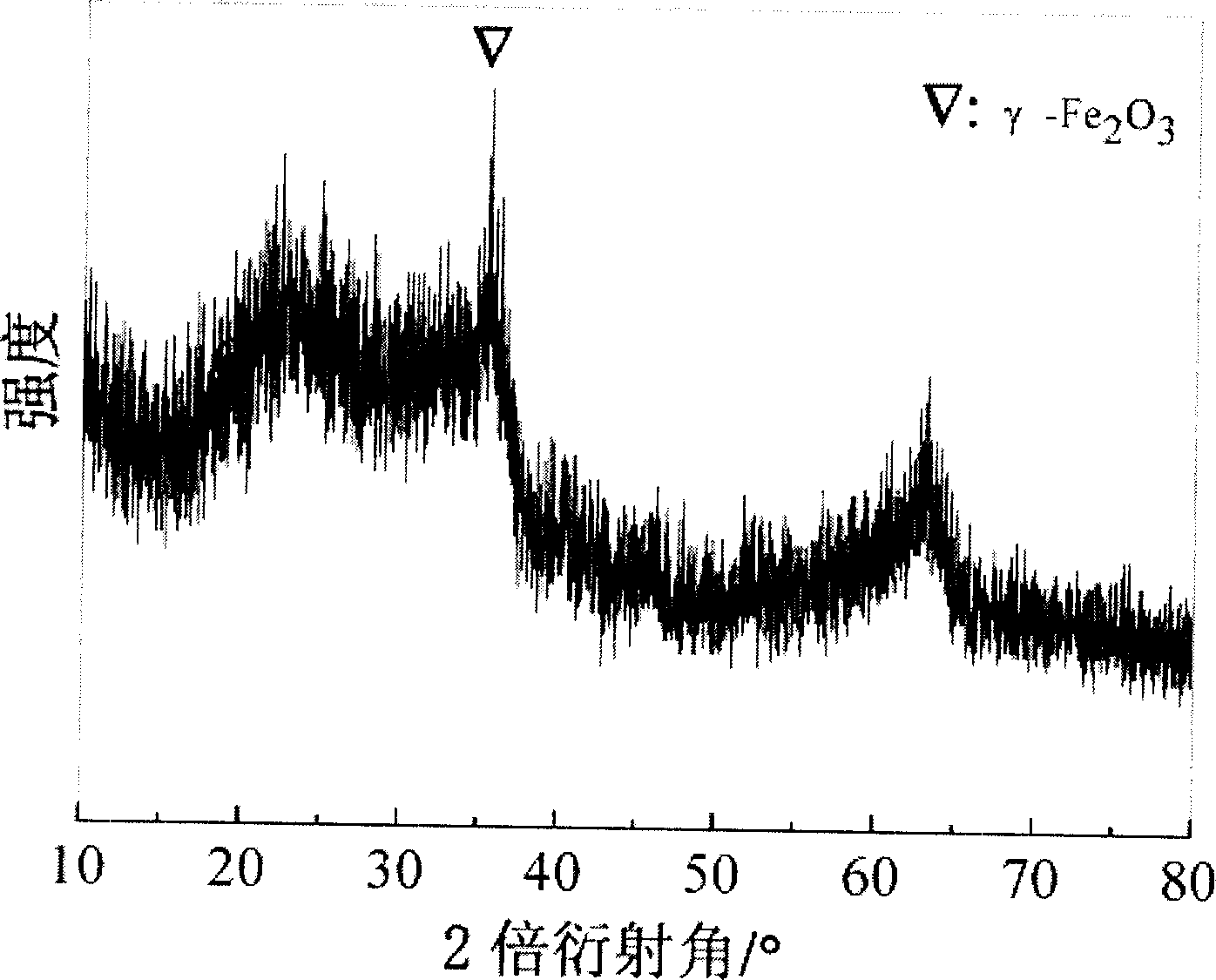

[0027] Example 1: SiO 2 / (γ-Fe 2 o 3 -SiO 2 ) Synthesis of magnetic carrier (primary coating)

[0028] (1) Ethyl orthosilicate, absolute ethanol, deionized water, Fe(NO 3 ) 3 9H 2O was formulated into a solution at a weight ratio of 1:2:5:0.5, stirred for 1 hour, and nitric acid was used as a pH control agent to control the pH value of the solution at about 0.7 to obtain a relatively stable sol, which was naturally gelled in the air. The gel was placed in an oven and slowly heated to 110°C to obtain a dry gel. Calcined at 700°C after grinding to obtain Fe 2 o 3 / SiO 2 composite oxides.

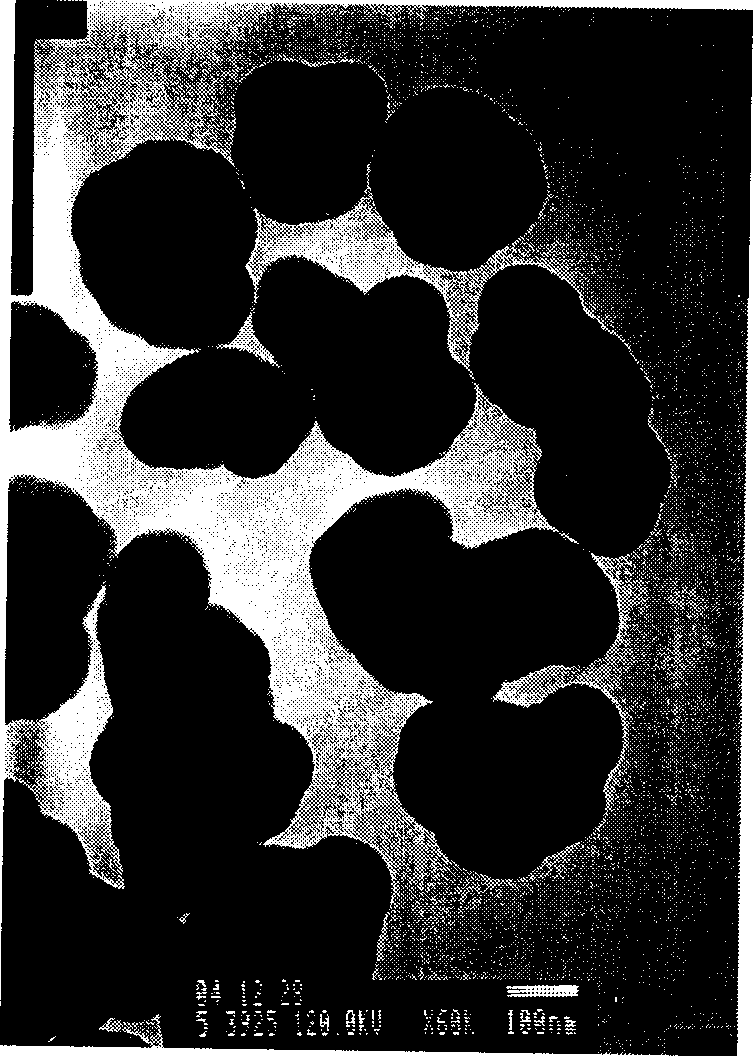

[0029] (2) Add 1.0g of the above-mentioned composite oxide particles to 40ml of absolute ethanol and sonicate for 30min, add 20ml of ethyl orthosilicate solution (4ml of ethyl orthosilicate + 16ml of absolute ethanol), and dropwise add 2ml of ammonia solution , reacted for 6 hours under stirring conditions to ensure complete hydrolysis of tetraethyl orthosilicate, and after centrifu...

Embodiment 2

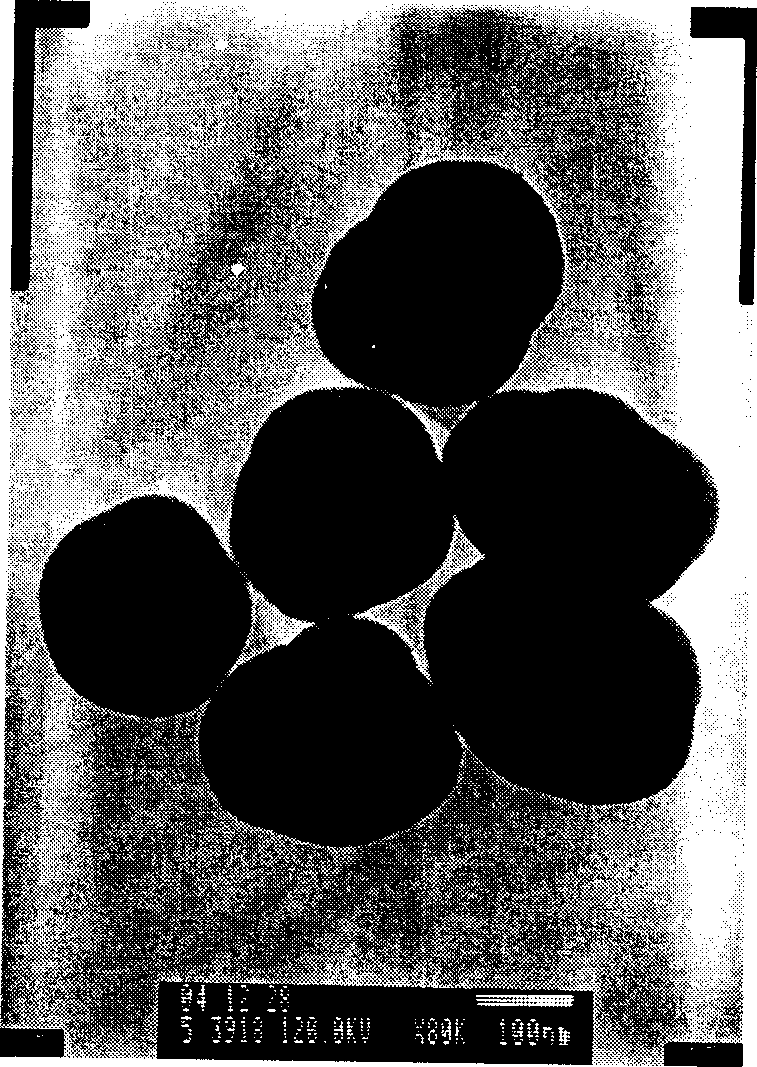

[0030] Example 2: SiO 2 / (γ-Fe 2 o 3 -SiO 2 ) Synthesis of magnetic carrier (multiple coatings)

[0031] After obtaining the magnetic carrier composite oxide in Example 1, repeat the operation according to the coating process described in step (2) in Example 1 to obtain the secondary SiO 2 The coated magnetic carrier, the transmission electron microscope photo of the second coated magnetic carrier is as follows image 3 shown.

Embodiment 3

[0032] Embodiment 3: with Al 2 o 3 Magnetic carrier coated for the third time

[0033] According to the step (1) of Example 1, 0.5 g of the product of Example 2 was added to 40 ml of deionized water, and ultrasonicated for 30 min, and 20 ml of sodium metaaluminate aqueous solution with a concentration of 0.05 g / ml was added, and 0.5 ml of Aqueous nitric acid solution with a concentration of 2 mol / l was reacted under stirring conditions for 6 hours, and after centrifugal filtration, the reactant particles were dried at 110°C to obtain Al 2 o 3 / (γ-Fe 2 o 3 -SiO 2 ) Magnetic catalyst carrier, which can be attracted by magnetic objects such as natural magnets and electromagnets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com