Insert tube of vacuum circulating degasification apparatus

A technology of vacuum cycle degassing and tube insertion, applied in the direction of improving process efficiency, can solve the problems of small circulating flow and inability to expand inner diameter, and achieve the effect of increasing steel output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the insertion tube for vacuum circulation degassing equipment of the present invention will be described in detail below in conjunction with the examples and accompanying drawings, but the specific implementation of the insertion tube for vacuum circulation degassing equipment of the present invention is not limited to the following examples.

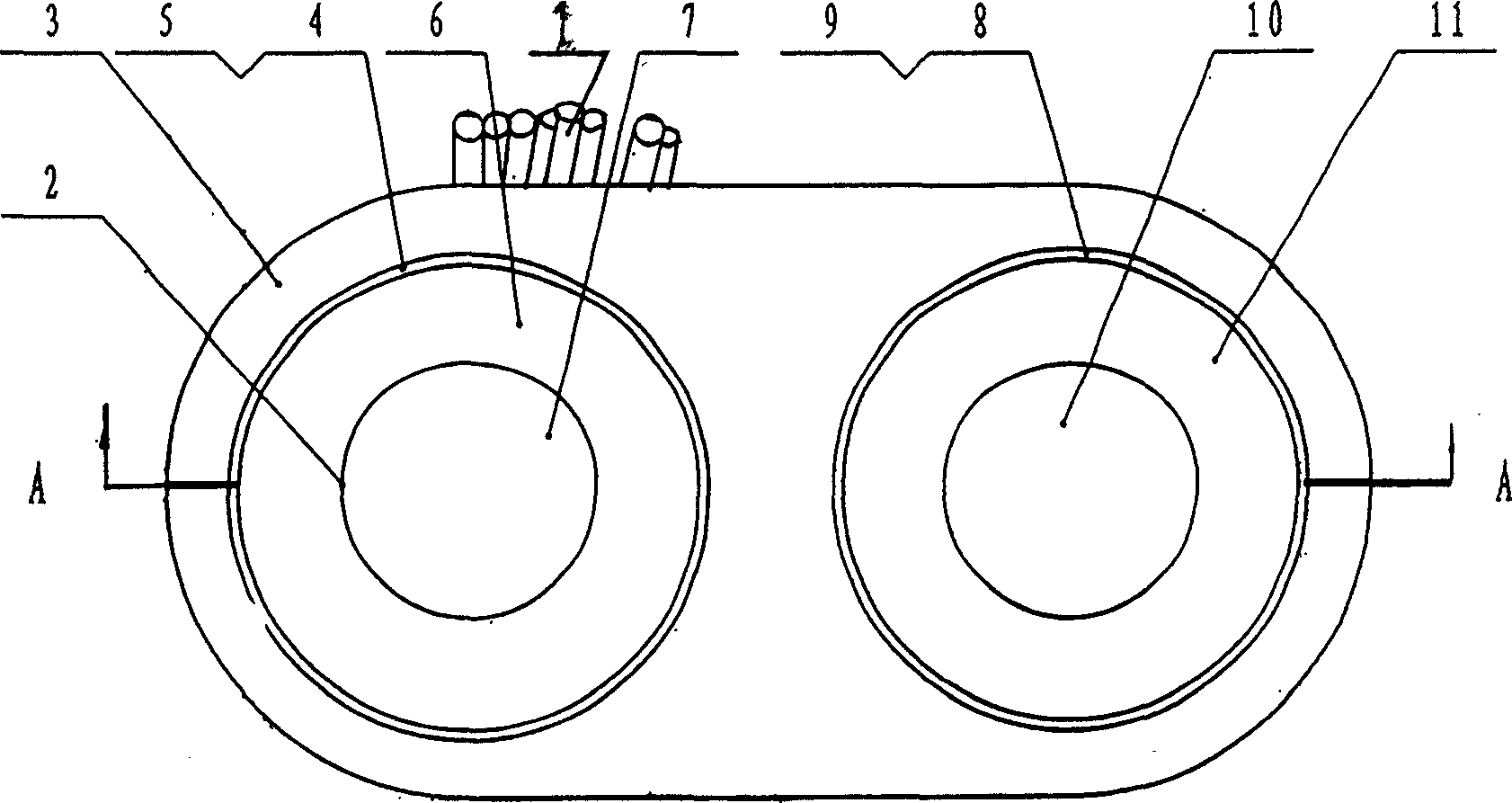

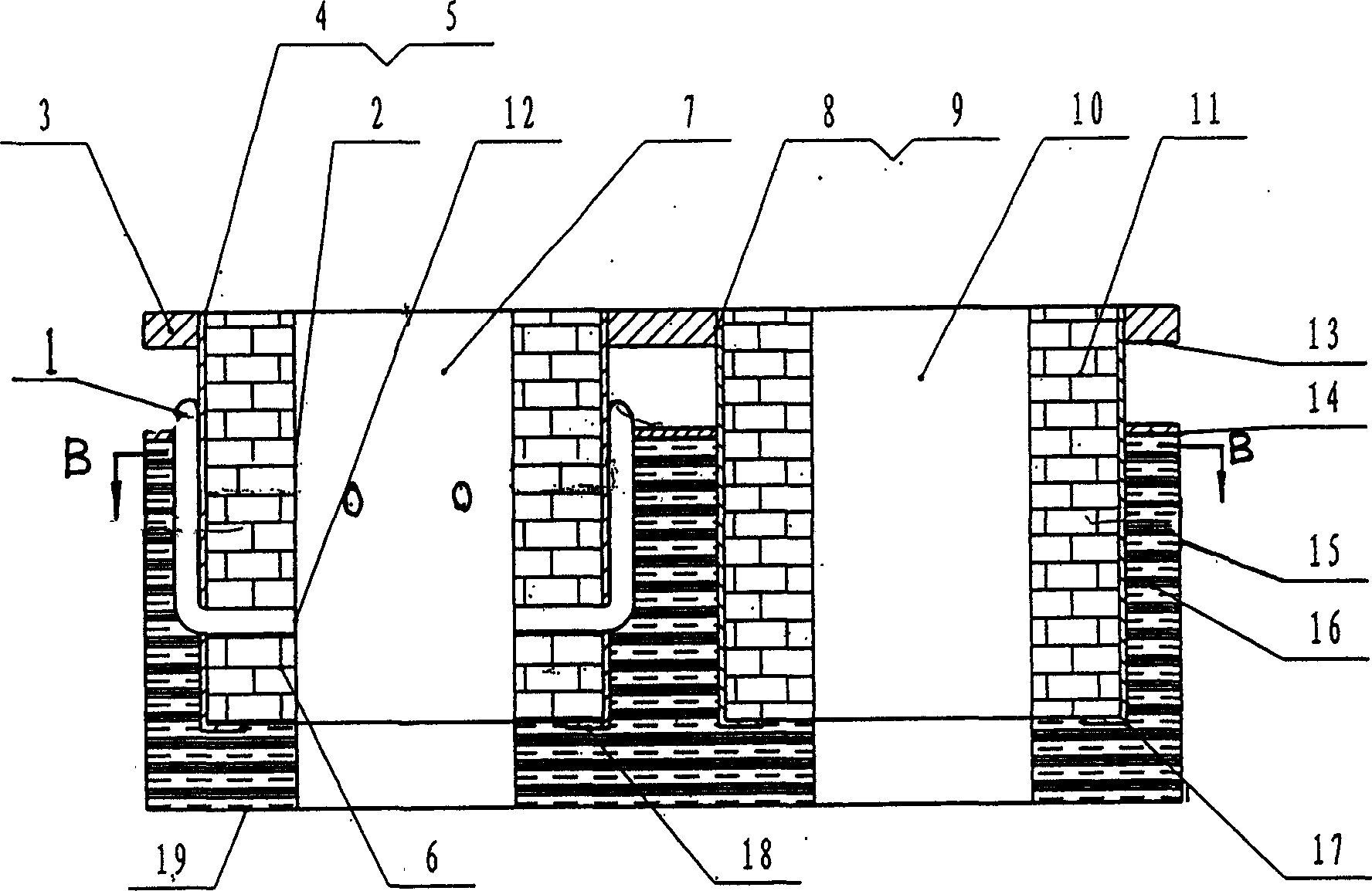

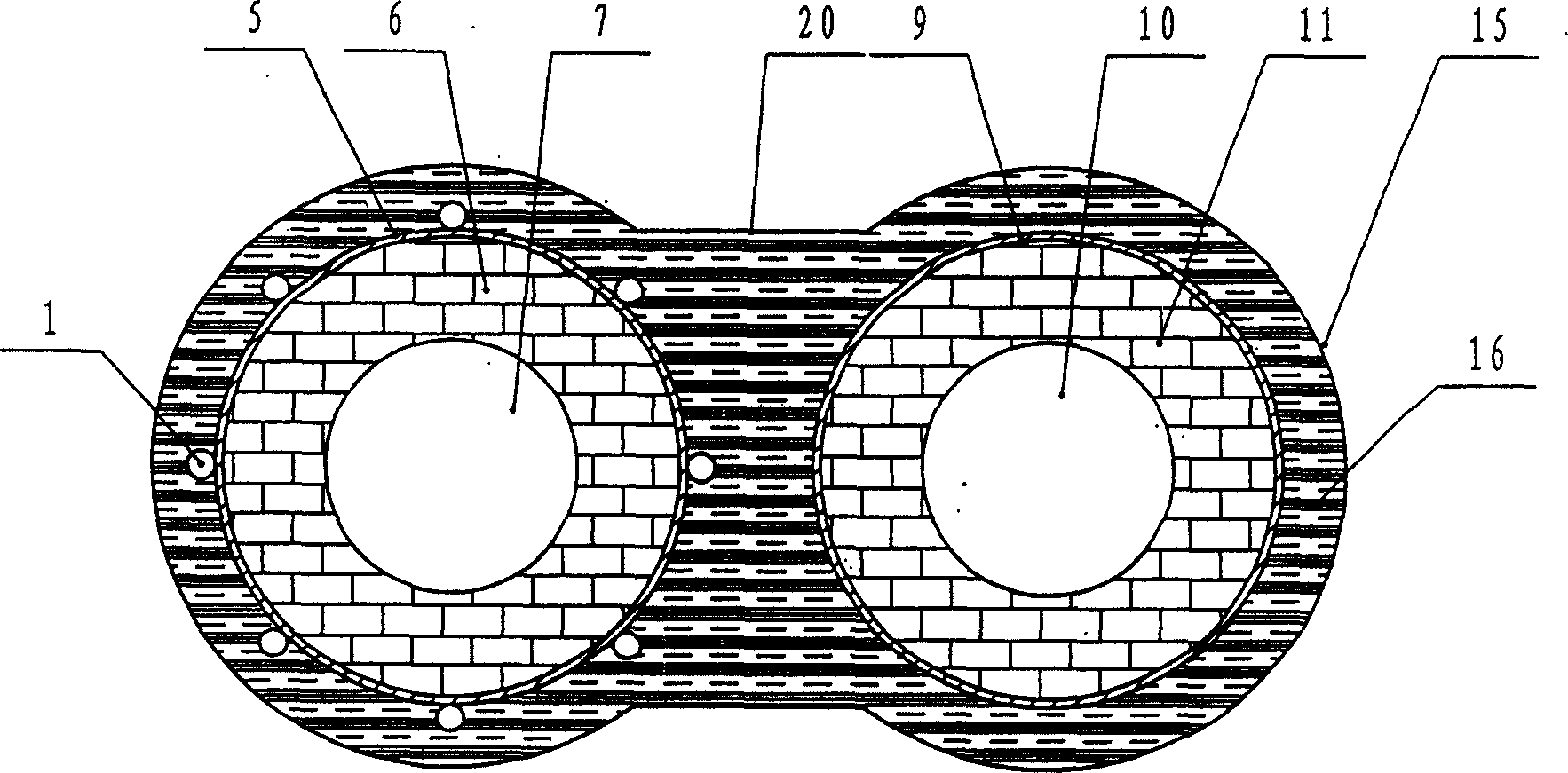

[0024] figure 1 , figure 2 and image 3 The described insertion tube for vacuum circulation degassing equipment includes a connecting flange, a steel cylinder, a refractory brick layer and a refractory cement sleeve. The lower opening of the steel cylinder is bent inward, and the upper opening of the steel cylinder is welded to the opening of the connecting flange. , the refractory cement sleeve is wrapped outside the steel cylinder, and the refractory brick layer is arranged in the steel cylinder. The inner side of the refractory brick layer is a through hole, and the through hole leads downward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com