Control process and control device of induction motor ind. appts.

A technology of an induction motor and a control method, which is applied in the direction of motor generator control, AC motor control, electronic commutation motor control, etc., can solve problems such as difficulty in obtaining high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

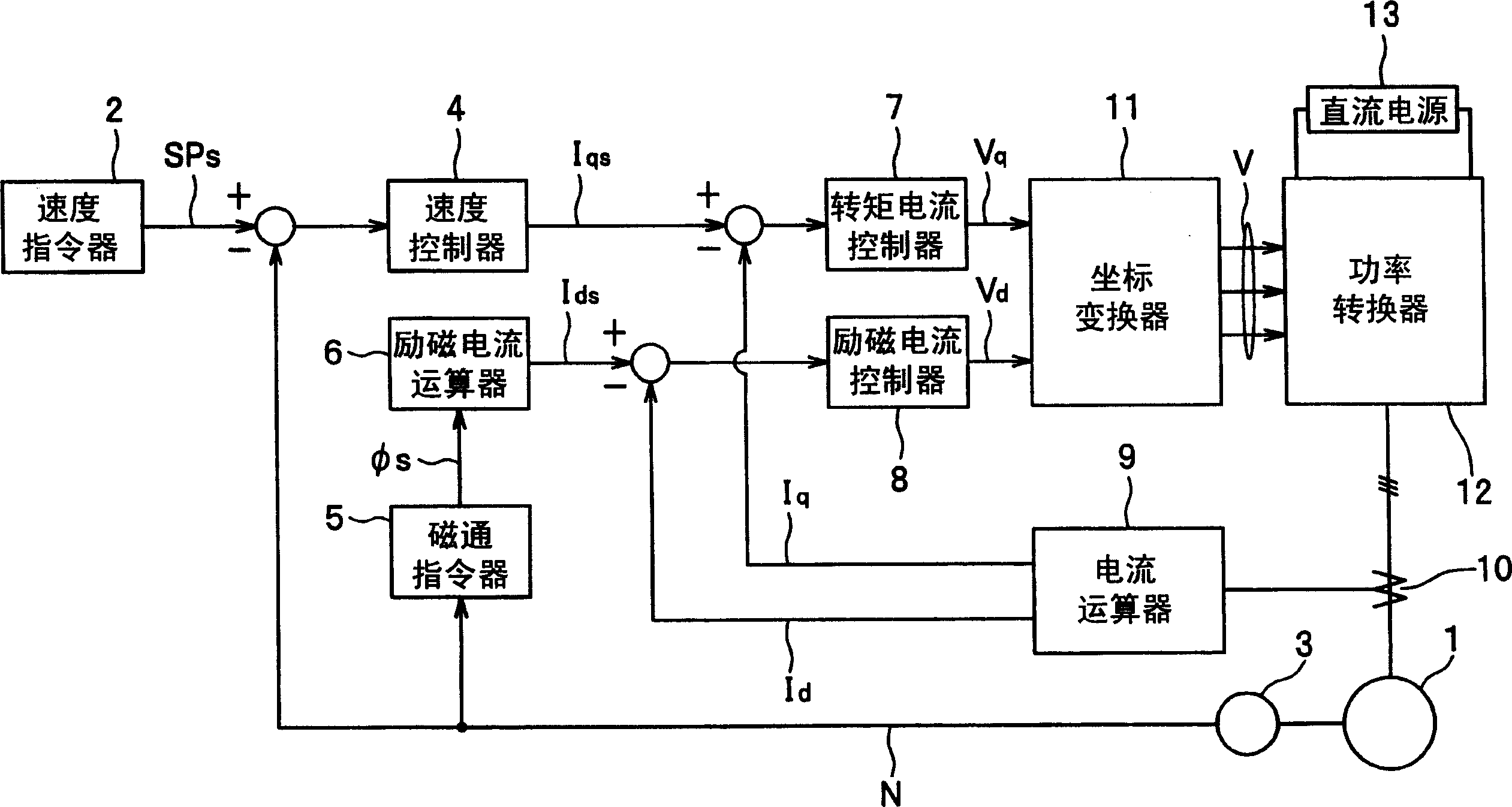

[0016] figure 1 , is a block diagram of the overall system including the control device for the induction motor according to the embodiment of the present invention.

[0017] figure 1 Among them, the induction motor 1 is driven according to the speed command SPs from the speed command device 2 . The speed command SPs is a target value of the rotational speed N (r / min). Furthermore, the induction motor 1 can be used, for example, in iron-making and non-ferrous equipment (hot-rolling equipment, cold-rolling equipment, processing line equipment), railway vehicles, coilers (including uncoilers), ships, construction machinery (for driving the main shaft) , paper machine equipment, conveying equipment and other purposes.

[0018] It will be specifically described below. The speed controller 4 outputs the torque current command Iqs to the torque current controller 7 based on the difference (SPs-N) between the speed command SPs and the rotational speed N of the induction motor 1 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com