Organic white light emitting diode in tiny cavity type

A technology of white light emission and diodes, which is applied in the direction of instruments, electrical components, circuits, etc., can solve the problems of white light color purity, color stability and low luminous efficiency, and achieve the problems of overcoming unstable luminous color, improving luminous efficiency, and enhanced luminous intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

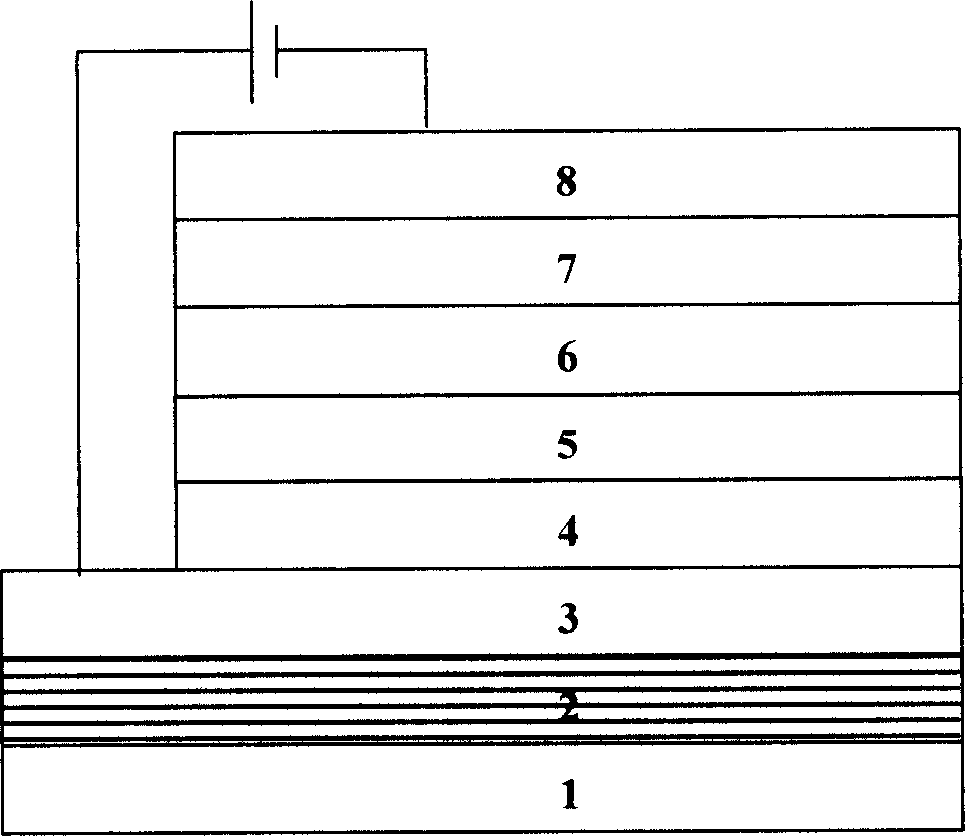

[0027] Embodiment 1: □ The structure of the organic microcavity light-emitting diode is:

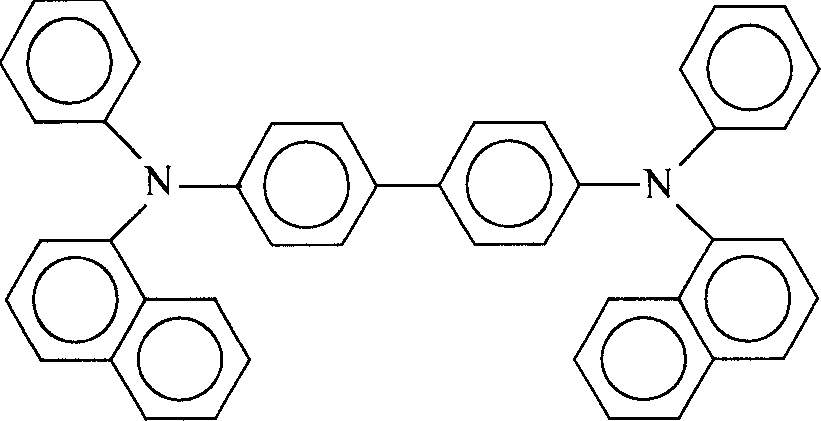

[0028] Glass substrate / Bragg mirror / ITO / NPB / Alq / F-TBB / OXD-7 / MgAg, where the substrate is ordinary optical glass. The structure of the Bragg reflector is HLH, a total of three layers, of which the material of the H layer is TiO 2 , thickness 57.3nm; L layer material is LiF, thickness 97.5nm. The maximum reflectivity of the Bragg mirror is about 70%. The transparent conductive film ITO is used as the anode with a thickness of 300nm. The hole transport layer is made of NPB material with a thickness of 83nm. The light-emitting layer is made of Alq material with a thickness of 20nm. The material of the light-emitting layer Alq is a broad-spectrum light-emitting material with a fluorescence peak at 510nm and a spectral line half-width of 90nm. The hole blocking layer is made of F-TBB material with a thickness of 20nm. The electron transport layer is made of OXD-7 material with a thicknes...

Embodiment 2

[0034] Embodiment 2: the structure that microcavity device adopts is: the structure of glass / Bragg reflector / ITO(156nm) / NPB(97nm) / Alq(72nm) / MgAg(150nm) Bragg reflector is three-layer HLH, wherein H Layer material is ZrO 2 / TiO 2 The mixture has a refractive index of 2.2 and a thickness of 62nm; the material of the L layer is LiF with a refractive index of 1.41 and a thickness of 98nm. The maximum reflectivity of the Bragg mirror is 60%. Depend on Figure 12 It can be seen that the electroluminescence spectrum of the microcavity device has two luminescence peaks, which are located at 467nm and 616nm. The luminescent color is white, and its 1931 CIE color coordinates are (0.357, 0.30) such as Figure 13 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com