Nano composite rubber material of absorbing wave, and method for fabricating products from the material

A nano-composite, rubber material technology, applied in the field of rubber materials, can solve the problems of secondary electromagnetic pollution, restricted promotion prospects, poor performance, etc., and achieve the effect of promoting upgrading, improving working and living environment, and low reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The nanocomposite wave-absorbing natural rubber material contains 90-120 parts of rubber; 1-6 parts of diethylpropylbenzene peroxide DCP; 1-4 parts of triallyl isocyanurate TAIC; 2-5 parts of zinc powder Zn; - 1-3 parts of acrylonitrile copolymer SA; 1-2 parts of anti-aging agent N.RD; 0.5-1.5 parts of anti-aging agent N.MB; silicon dioxide SiO 2 Or 30-40 parts of carbon black; 6-12 parts of dioctyl sebacate DOS; 0.6-1.2 parts of polyvinyl fluoride PW; 8-40 parts of nano-β-silicon carbide; 1-6 parts of nano-nickel powder; 8-22 parts parts polyaniline.

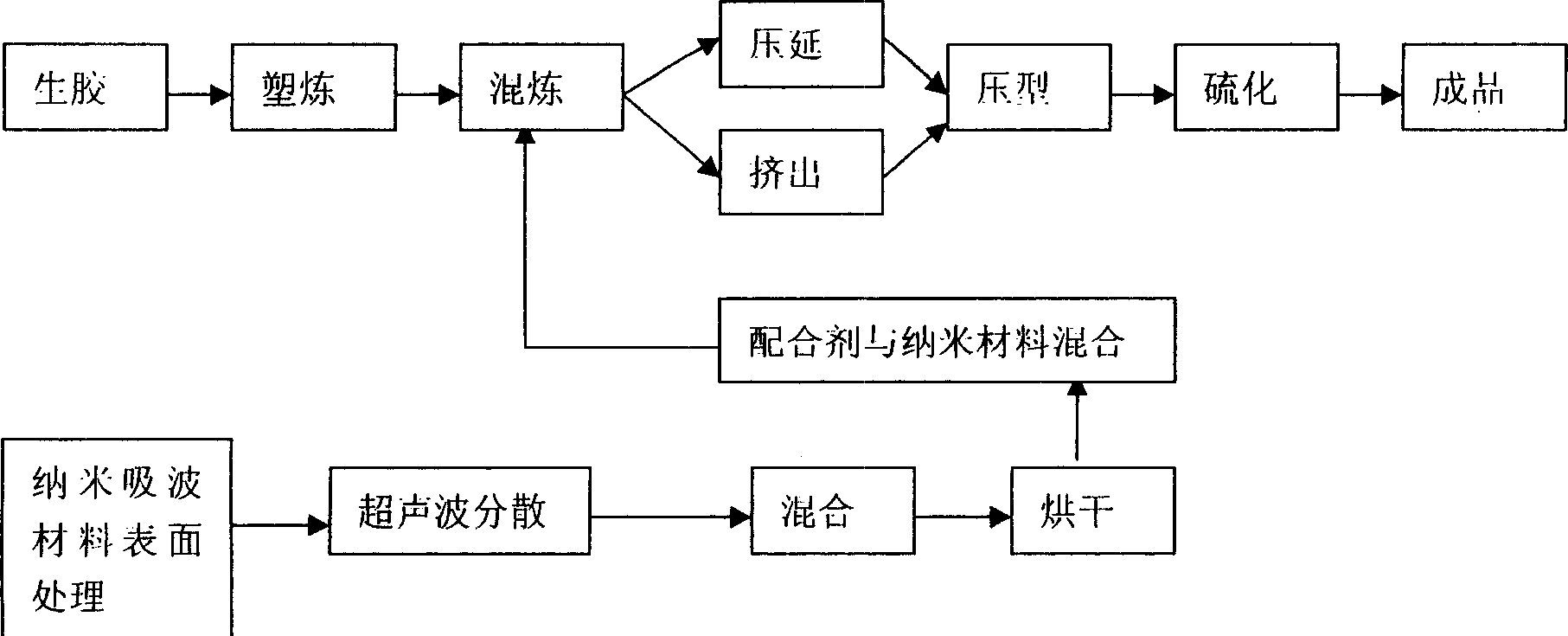

[0062] The preparation method of product is carried out according to the following steps:

[0063] a. Take the required weight of the rubber body according to the proportion ratio for later use, and weigh the required weight for the compounding agent according to the proportion ratio for later use;

[0064] b. Preparation of nano-masterbatch: Weigh the required weight of nano-β-silicon carbide, nano-nickel powder, and ...

Embodiment 2

[0071] The nanocomposite wave-absorbing natural rubber material contains 90 parts of rubber; 6.0 parts of diethylpropylbenzene peroxide DCP; 4.0 parts of triallyl isocyanurate TAIC; 5.0 parts of zinc powder Zn; styrene-acrylonitrile copolymer SA 3.0 parts; anti-aging agent N.RD 2.0; anti-aging agent N.MB 1.5 parts; silicon dioxide SiO 2 Or carbon black 40.0; dioctyl sebacate DOS 12.0 parts; polyvinyl fluoride PW 1.2 parts; 40.0 parts of nano-β-silicon carbide; 6.0 parts of nano-nickel powder; 22.0 parts of polyaniline. The preparation method of product is with embodiment 1

Embodiment 3

[0073] The nanocomposite wave-absorbing natural rubber material contains 100 parts of rubber; diethylpropylbenzene peroxide DCP: 5.0 parts; triallyl isocyanurate TAIC 3.0 parts; zinc powder Zn 4.0 parts; styrene-acrylonitrile copolymer SA 2.0 parts; anti-aging agent N.RD 2.0 parts; anti-aging agent N.MB 1.0 parts; silicon dioxide SiO 2 Or 38.0 parts of carbon black; 10.0 parts of dioctyl sebacate DOS; 1.0 parts of polyvinyl fluoride PW; 30.0 parts of nano-β-silicon carbide; 5.0 parts of nano-nickel powder; 18.0 parts of polyaniline. The preparation method of product is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com