Manufacturing method of multifunction integrated sensor chip

A technology for integrating sensors and manufacturing methods, which is applied in the manufacture of semiconductor/solid-state devices, the manufacture of microstructure devices, and processes for producing decorative surface effects, etc. Small size, easy to package and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

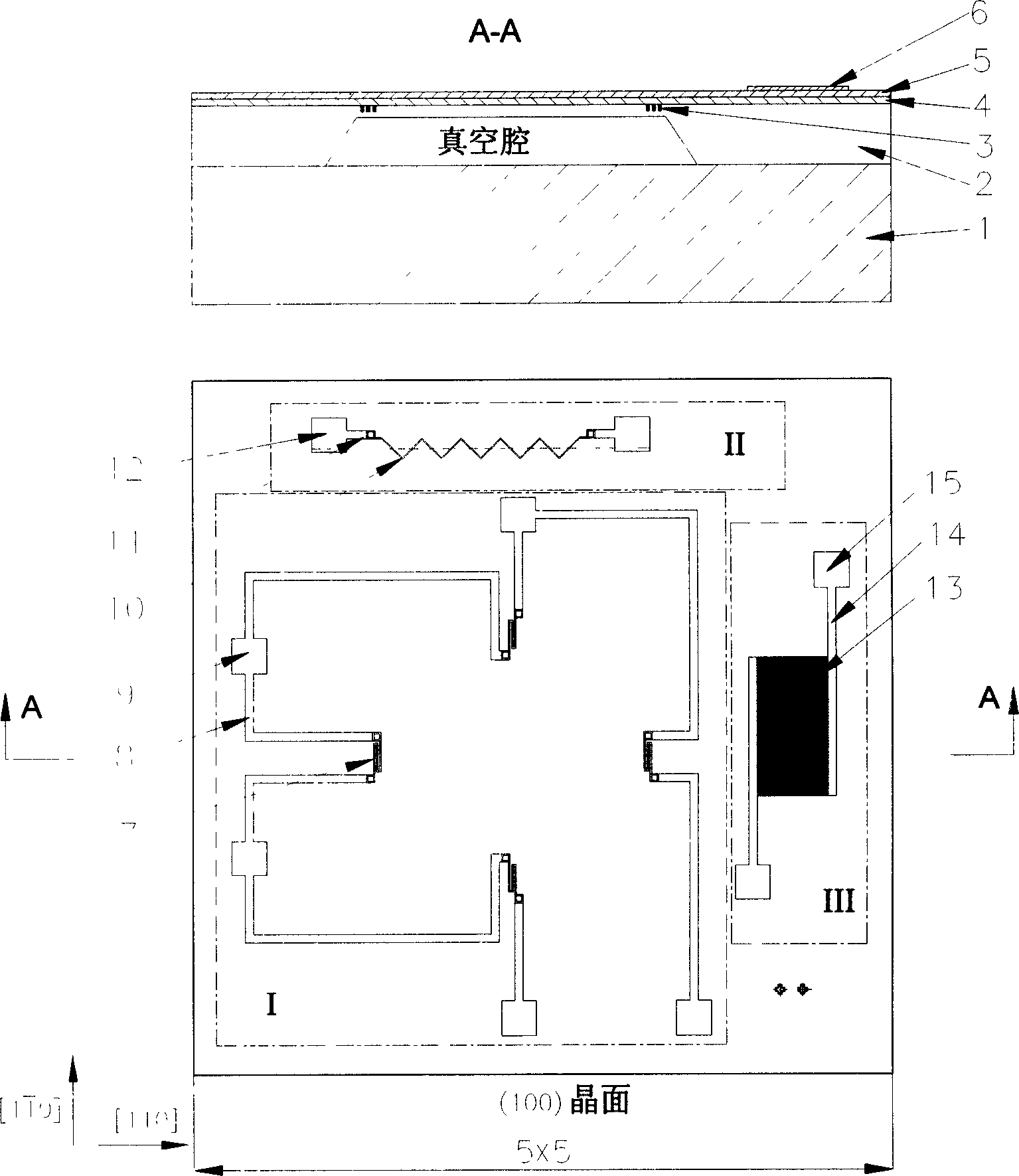

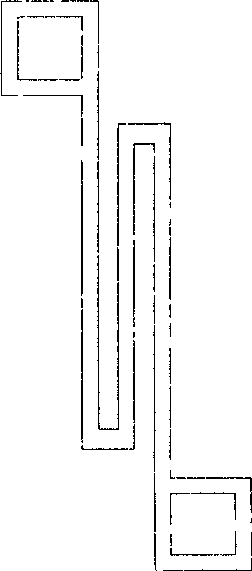

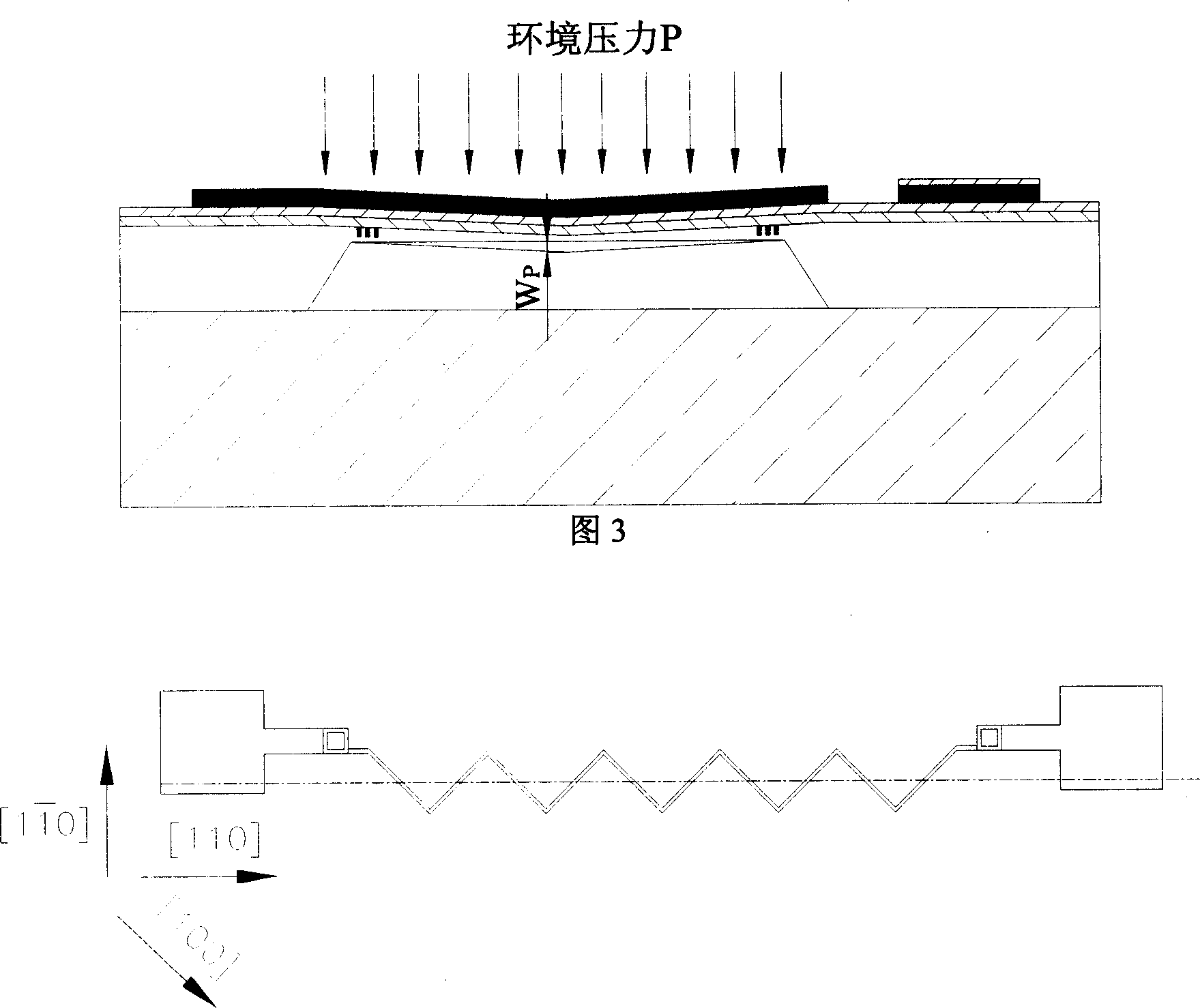

[0029] Refer to figure 1 , The present invention uses MEMS technology and integrated circuit micro-processing technology to make three sensitive units on a (100) crystal plane and 5mm×5mm die: pressure I, temperature II and humidity unit III. The backside of pressure unit I is C-type silicon The cup, temperature II and humidity unit III are arranged in the fixed branch area of the die to eliminate the influence of pressure on the temperature and humidity unit. The chip is packaged on the borosilicate glass 1 through a vacuum bonding process. The key technology is the manufacturing process. Compatibility in the process. The three units are based on different effects. Among them, the pressure unit is based on the piezoresistive effect and is mainly used to detect the pressure change of the environment; the temperature unit is based on the thermal resistance effect and is used to detect changes in the ambient temperature; the humidity unit is based on the capacitance principle and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com