Method for mfg. nano self-cleaning type wood composite material

A composite material and manufacturing method technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve problems such as carcinogenicity and damage to physical health, and achieve the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 0.03g / cm 2 Anatase Nano Solid Powder TiO 2 Mix it with phenolic resin in a ratio of 1:2 by weight, evenly brush it on the phenolic resin impregnated paper, hang it outdoors to air-dry until it is not sticky to hands, then put it into an oven at 80°C, bake for 6 minutes, take it out and save it.

[0016] Urea-formaldehyde resin glue (free formaldehyde content is 1.01%) is used as an adhesive, and wood particleboard is pressed according to the following process parameters:

[0017] Particle board specification: 50×50×1cm

[0018] Particleboard bulk density: 0.65g / cm 3

[0019] Glue amount: 10%

[0020] Hot pressing temperature: 160°C

[0021] Hot pressing pressure: 3MPa

[0022] Hot pressing time: 0.6min / mm plate thickness

[0023] Remove the trimmed slab and sand both surfaces with wood sandpaper to remove the pre-cured layer. Choose veneer temperature as 135°C, time 6min, pressure 1.4MPa.

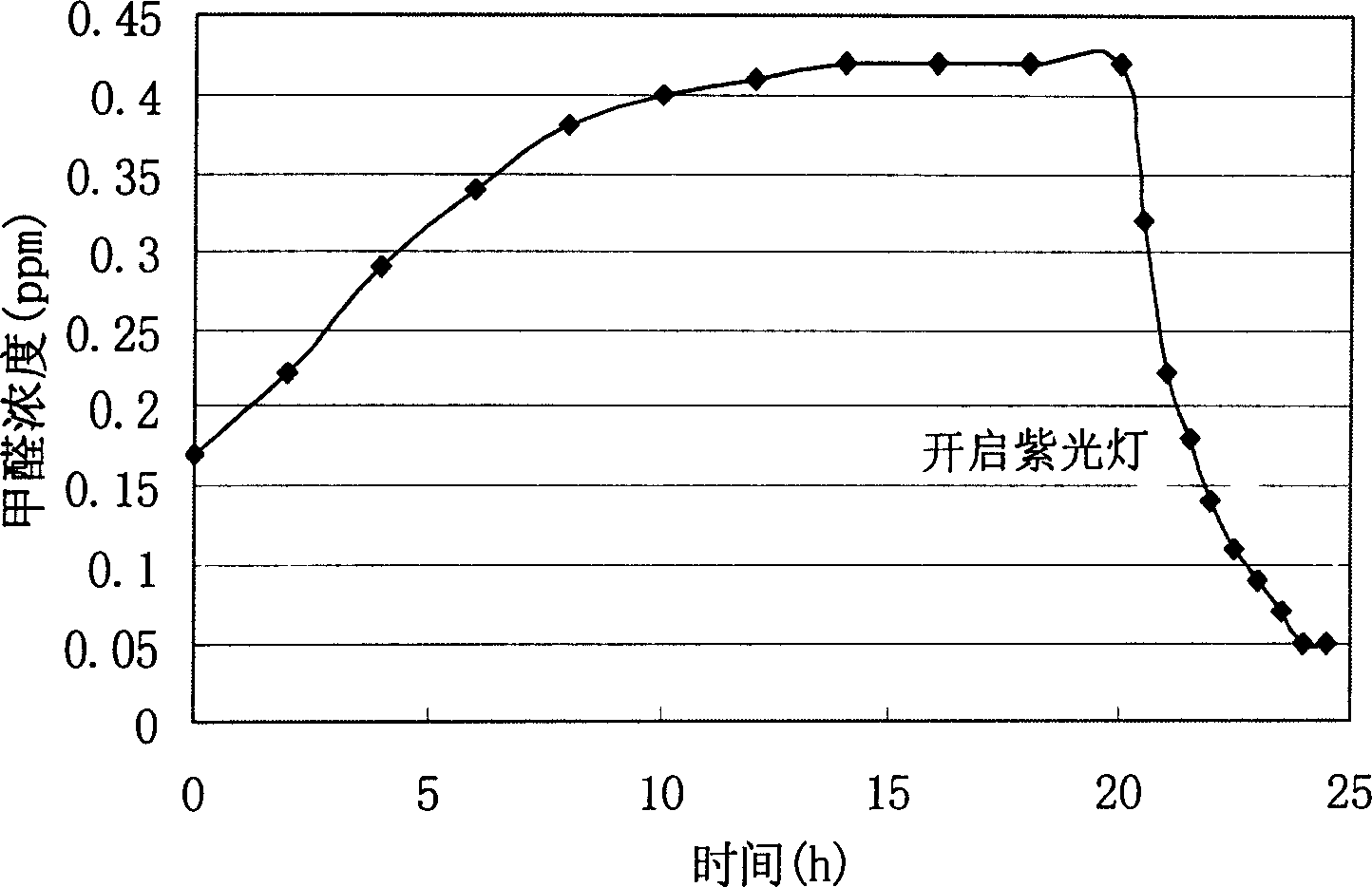

[0024] Place the two pieces of veneered particleboard in a closed conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com