Stepped upper electrode for plasma processing uniformity

A plasma and plasma chamber technology, applied in the field of stepped upper electrodes for uniform plasma processing, can solve the problem of reducing the etching rate near the edge of the processed substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

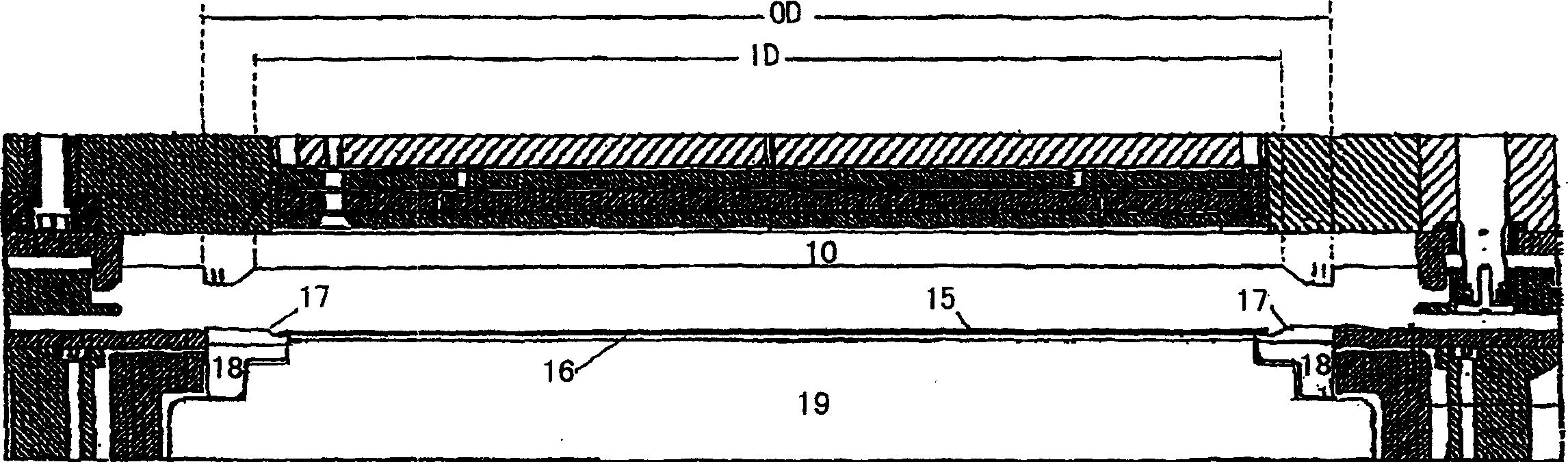

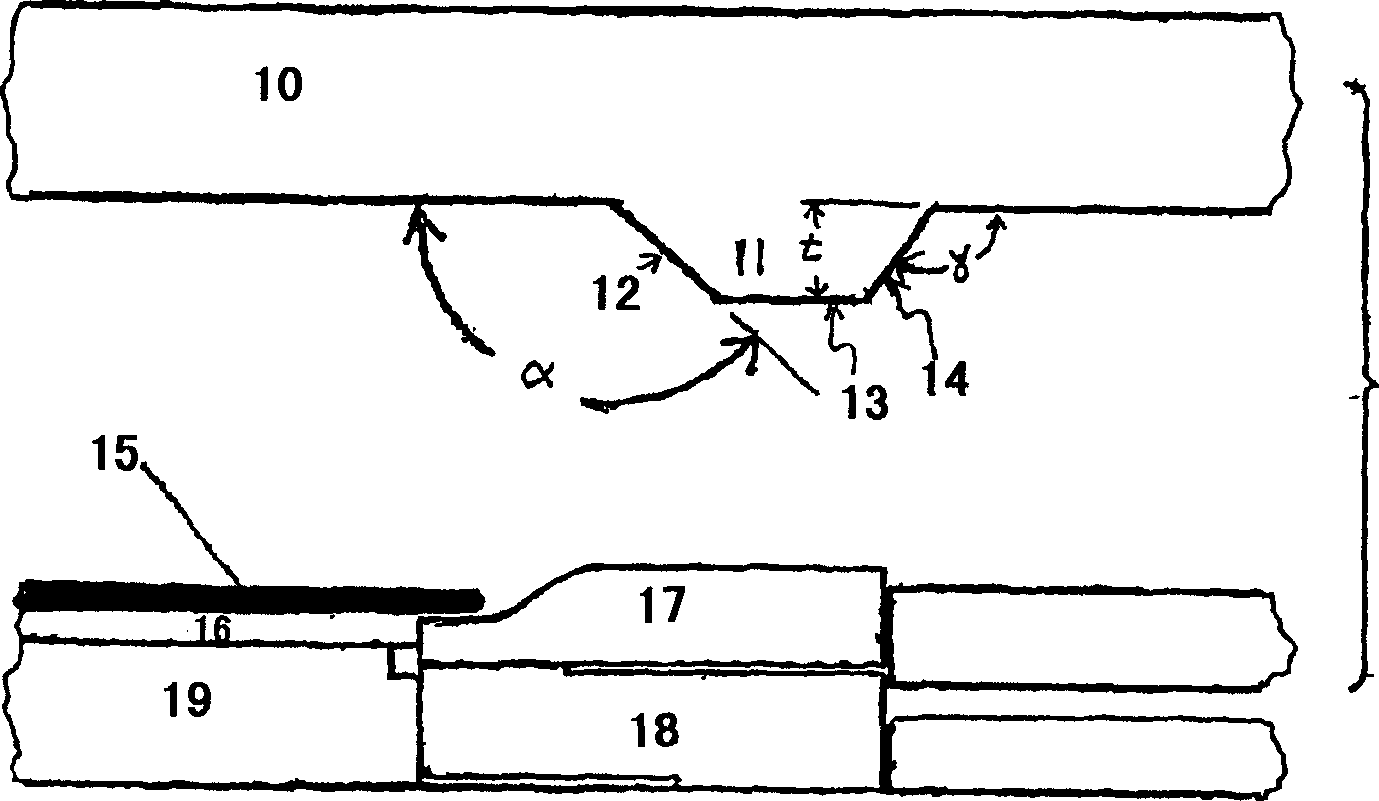

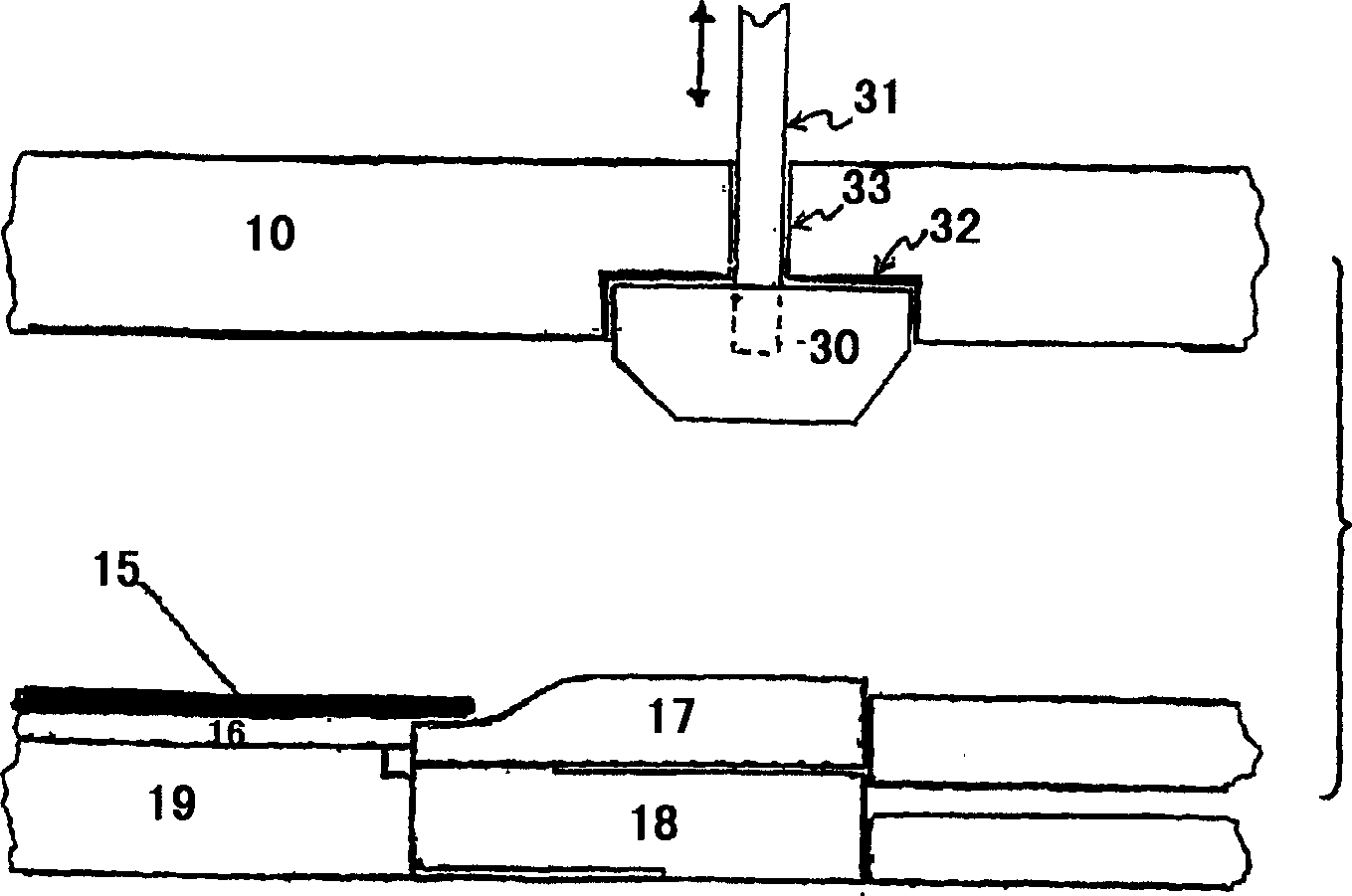

[0033] The present invention provides a novel arrangement for improving uniformity during plasma processing of semiconductor substrates such as silicon wafers, flat panel display substrates, and the like. This improved plasma processing can be achieved by adjusting the plasma density on the peripheral region of the substrate being processed. Uniformity can be improved by using stepped electrodes. Further improvements can be made by changing the material, shape and / or power of the hot edge ring (HER) surrounding the substrate being processed.

[0034] The stepped electrode according to the present invention can be applied to the plasma etching process to increase the plasma density near the edge of the wafer in the parallel plate plasma reaction chamber, so as to obtain a more uniform etching rate on the substrate. Although the invention has been described based on the advantages of a plasma etch process, the invention can also be used in other applications requiring a uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com