Vertical external cavity face emitting semiconductor laser with concave-convex mirror

A reflective mirror and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of reducing device efficiency and output power, increasing device lasing threshold, etc., to improve output power, facilitate beam coupling, good effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

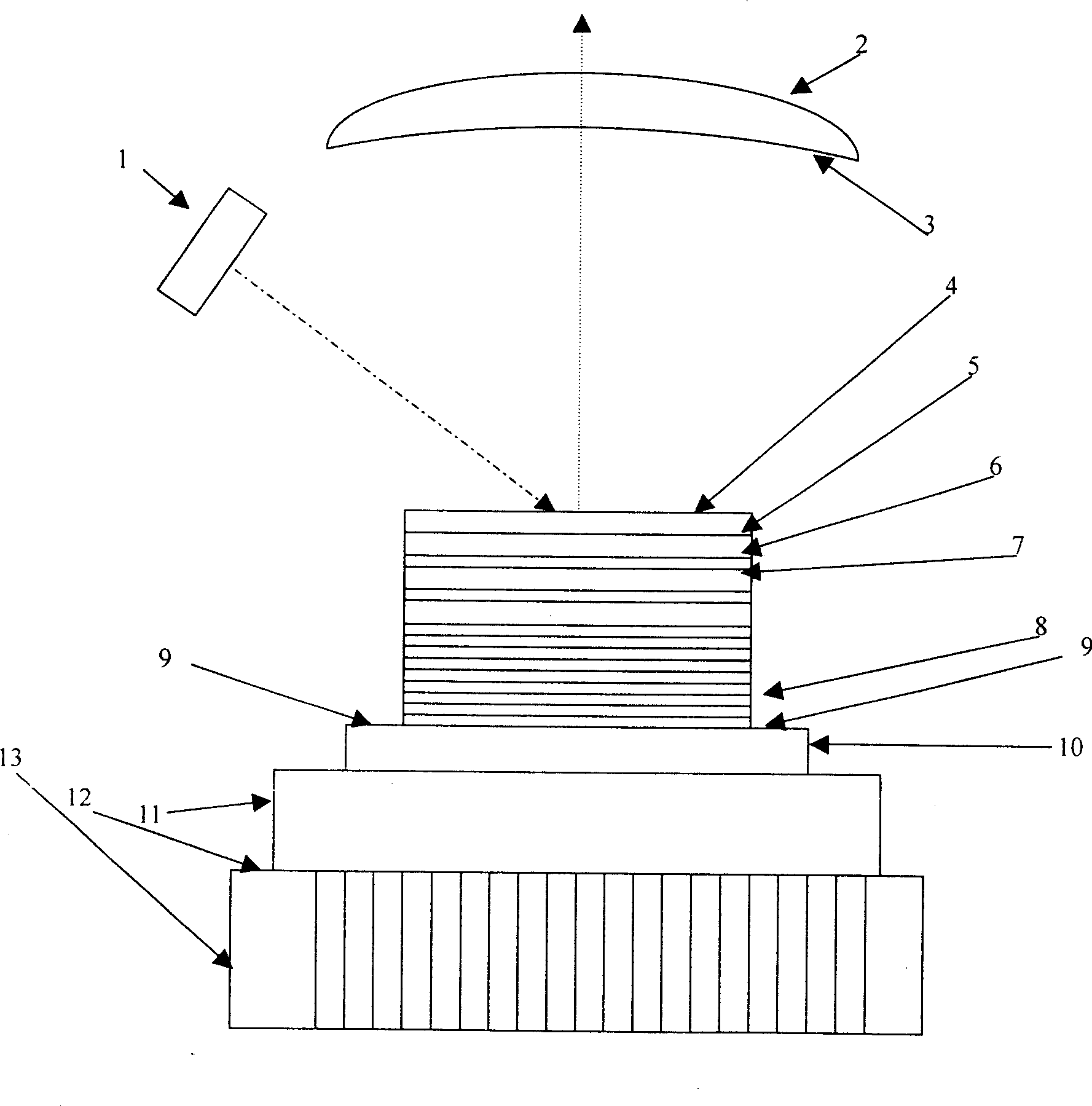

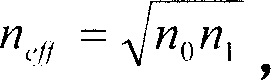

[0011] The pump light source 1 is a high-power 800-810nm wavelength semiconductor laser array, the convex-convex mirror 2 is made of k9 optical glass or quartz, the concave surface curvature half-diameter is 5 mm or 25 mm, and the convex surface curvature radius is 5 mm or 9.5 mm , the highly reflective dielectric film 3 adopts Si / SiO2 dielectric film, and the reflectivity is 95%-99%. The anti-reflection coating 4 is made of HfO2 material, and the effective refractive index selected by the anti-reflection coating is n eff = n 0 n 1 , The effective refractive index of HfO2 material selection is 1.85-1.90. The window layer 5 is made of GaIn0.49P material. The light absorbing layer 6 is made of Al0.06GaAs material. The active gain region 7 can be a periodic active multi-quantum well gain region, and its diameter can be fro...

Embodiment 2

[0013] Embodiment 2: pumping light source 1, reflective medium film 3, anti-reflection film 4 and window layer 5, solder 9, heat sink 10, heat sink 11, thermal conductive adhesive 12 and microchannel heat sink 13 are the same as in embodiment 1, with convex and concave The semi-diameter of curvature of the concave surface of the reflecting mirror 2 is 50 mm, and the radius of curvature of the convex surface is 25 mm. The light absorbing layer 6 is Al0.2GaAs, the periodic multi-quantum well active gain region 7 is GaAs quantum wells and Al0.2GaAs potential barriers, and the Bragg reflector 8 is made of 30 pairs of AlAs / Al0.2GaAs materials. The present invention is the same as Embodiment 1 in terms of process.

Embodiment 3

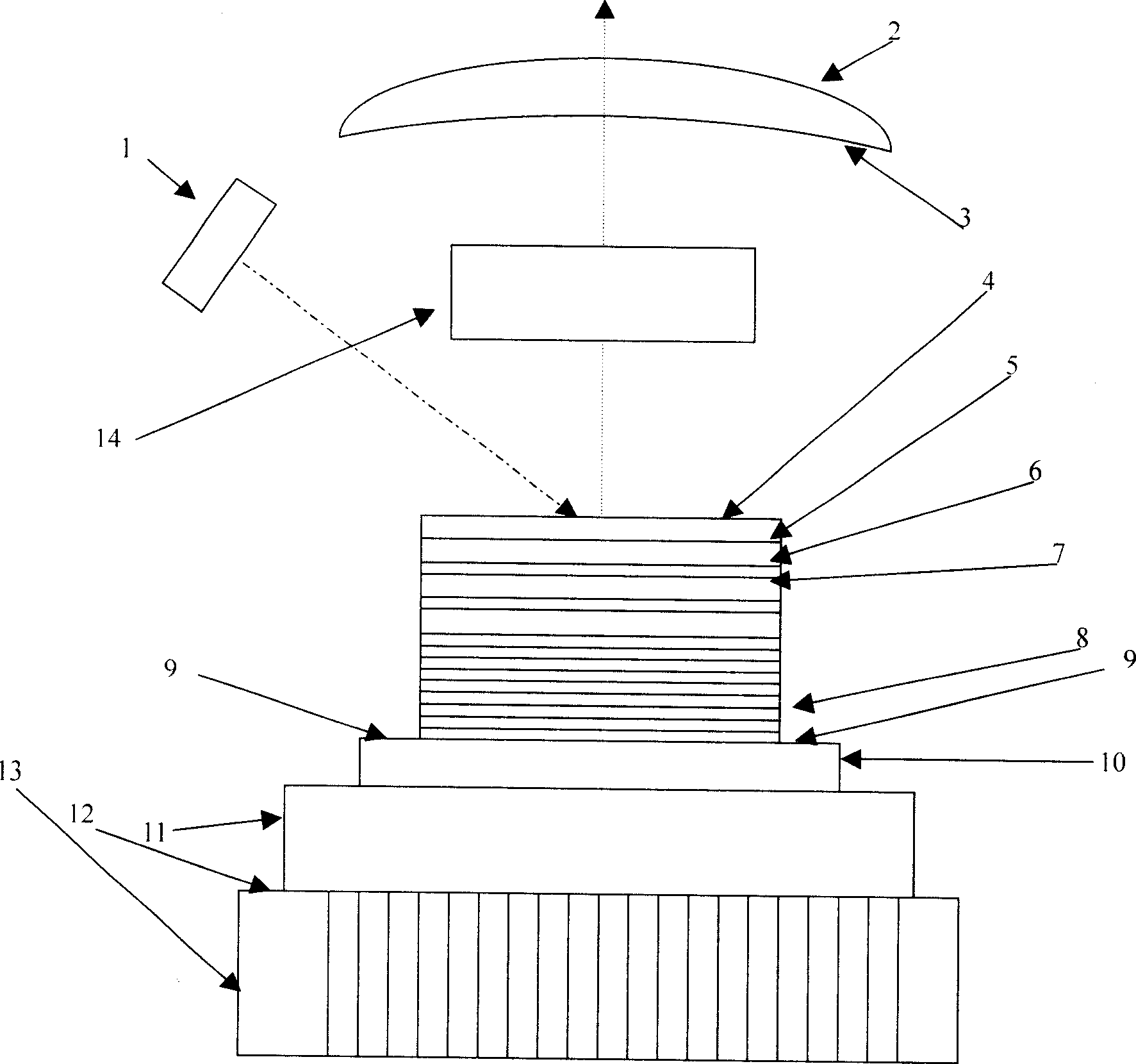

[0014] Embodiment 3: frequency doubling in the cavity of a 980nm vertical external cavity surface-emitting semiconductor laser with a convex-concave mirror, the nonlinear crystal 14 is an LBO crystal, the concave curvature of the convex-concave mirror 2 is selected to be 100 mm, and the convex curvature radius can be selected to be 50 mm . Other components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com