Multilayer ceramic capacitor

A ceramic capacitor, stacked type technology, applied in the direction of stacked capacitors, multiple fixed capacitors, fixed capacitor dielectrics, etc., can solve the problem of not being fully applicable to motor vehicle electronic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

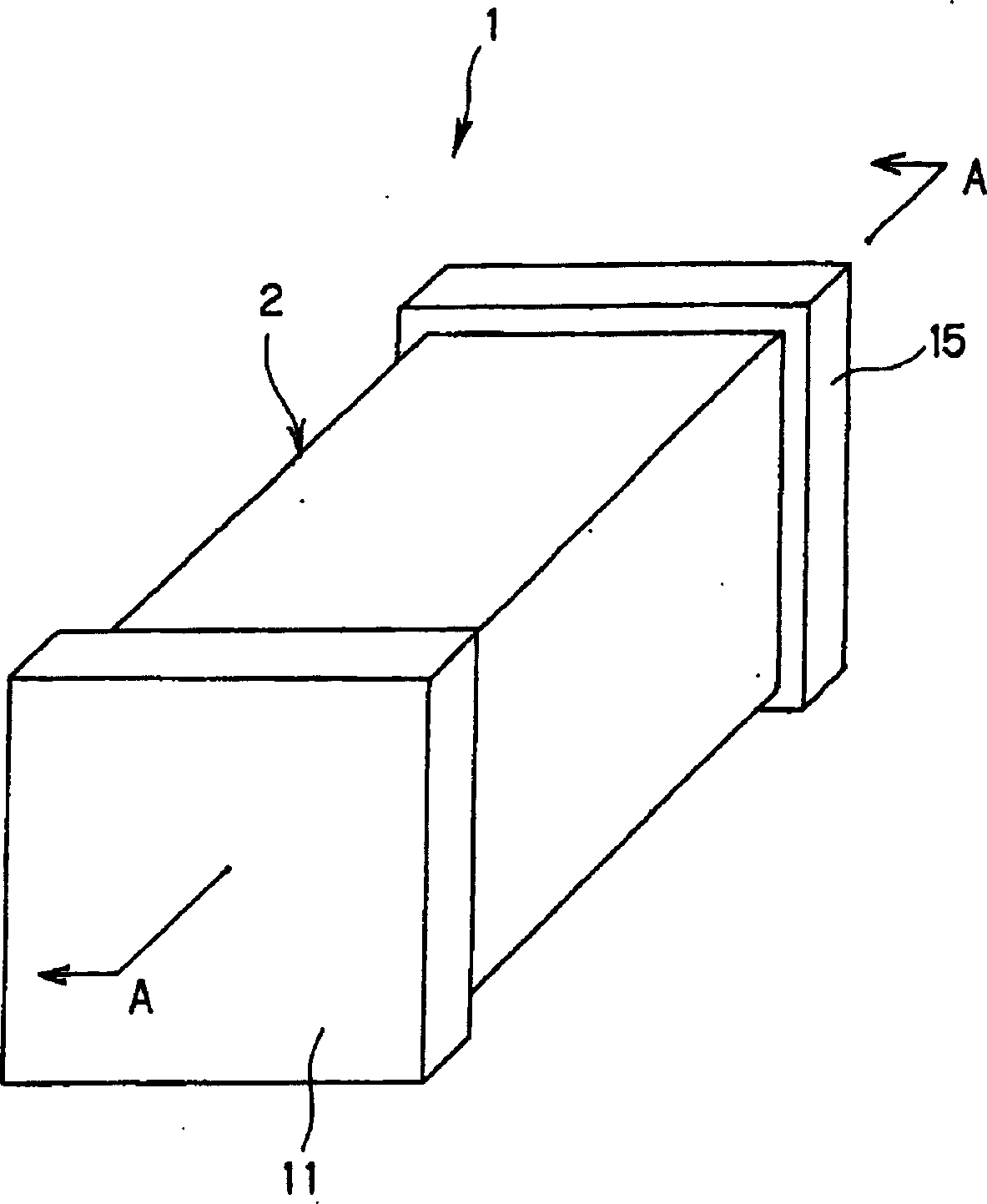

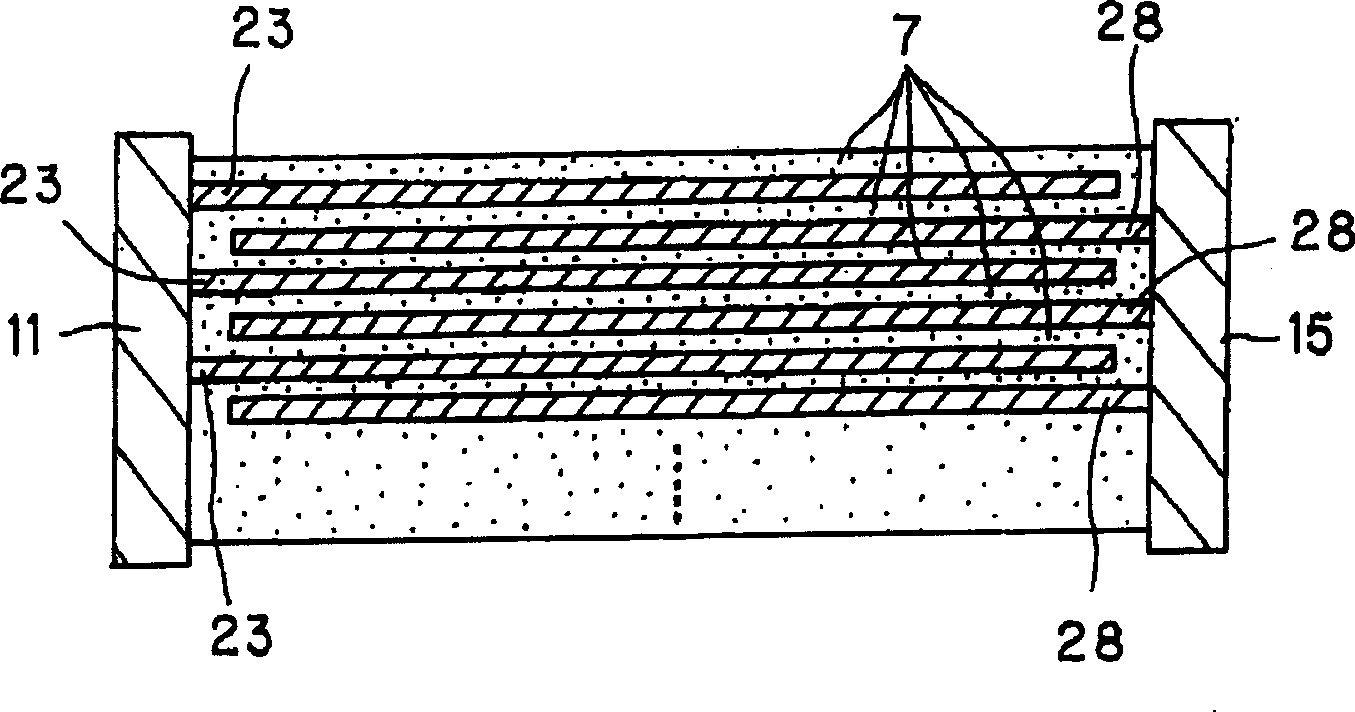

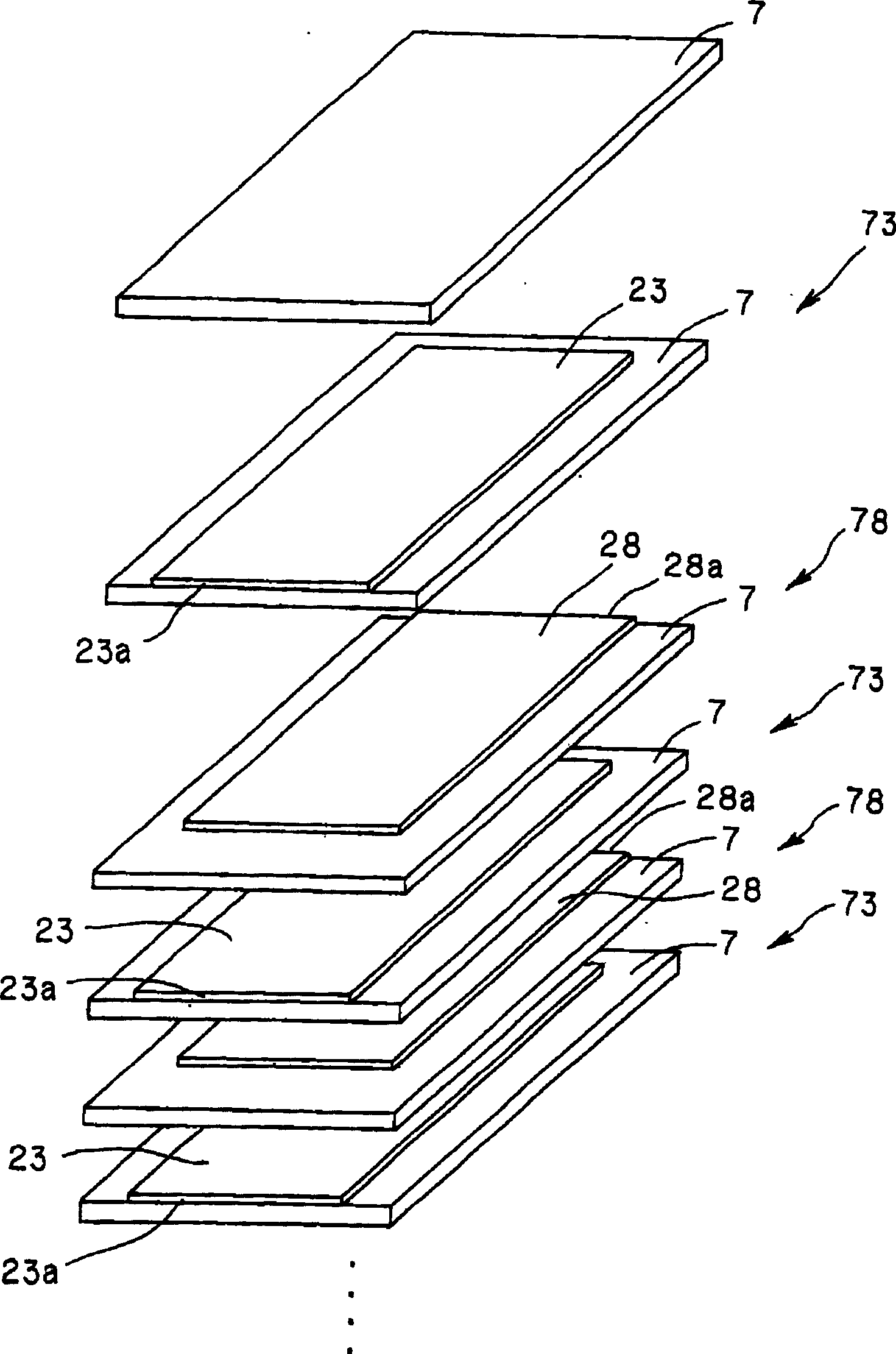

[0080] (1) Preparation of sheet-like laminate (device body)

[0081] When the so-called printing method is applied, the paste for forming a dielectric layer and the paste for forming an internal electrode layer are sequentially laminated and printed on a support such as polyethylene terephthalate. At this time, the first internal electrode layer 11 and the second internal electrode layer 15 are respectively as follows: figure 2 or image 3 As shown, printing is performed on the outer frame of the paste for forming a dielectric layer so as to obtain a predetermined form. After the dielectric layer and the internal electrode layer are sequentially laminated and printed, they are cut into a sheet in a predetermined shape, and then peeled off from the support to form a sheet-shaped laminate (prototype of the element body).

[0082] In addition, when the so-called sheet method is employed, a plurality of dielectric green sheets are formed using a paste for forming a dielectric l...

Embodiment 1

[0119] As starting materials for the preparation of dielectric materials, main component materials (BaTiO 3 ) and raw materials for the first to seventh subcomponents.

[0120] MgCO is used as the first subcomponent raw material 3 ,

[0121] Used as the second subcomponent raw material (Ba 0.6 Ca 0.4 ) SiO 3 ,

[0122] Use V as the third subcomponent raw material 2 o 5 ,

[0123] Yb is used as the raw material of the fourth subcomponent (R1) 2 o 3 ,

[0124] CaZrO is used as the fifth subcomponent raw material 3 and organometallic salts of Ca and Zr,

[0125] Use Y as the sixth subcomponent (R2) raw material 2 o 3 ,

[0126] MnCO is used as the seventh subcomponent raw material 3 .

[0127] In addition, the second subcomponent raw material (Ba 0.6 Ca 0.4 ) SiO 3 was prepared as follows: BaCO 3 , CaCO 3 and SiO 2 It was placed in a ball mill for 16 hours of wet mixing, then dried, sintered in air at 1150° C., and then placed in a ball mill for 100 hours o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com