Method for extracting saponin active ingredient from pseudo-ginseng

A technology of active ingredients and saponins, applied in the field of extraction of active ingredients of natural medicines, can solve the problems of low extraction rate of active ingredients, large energy consumption for subsequent concentration, large amount of solvent, etc., and achieves reduction of extraction time, reduction and increase of solvent consumption. The effect of extracting the driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

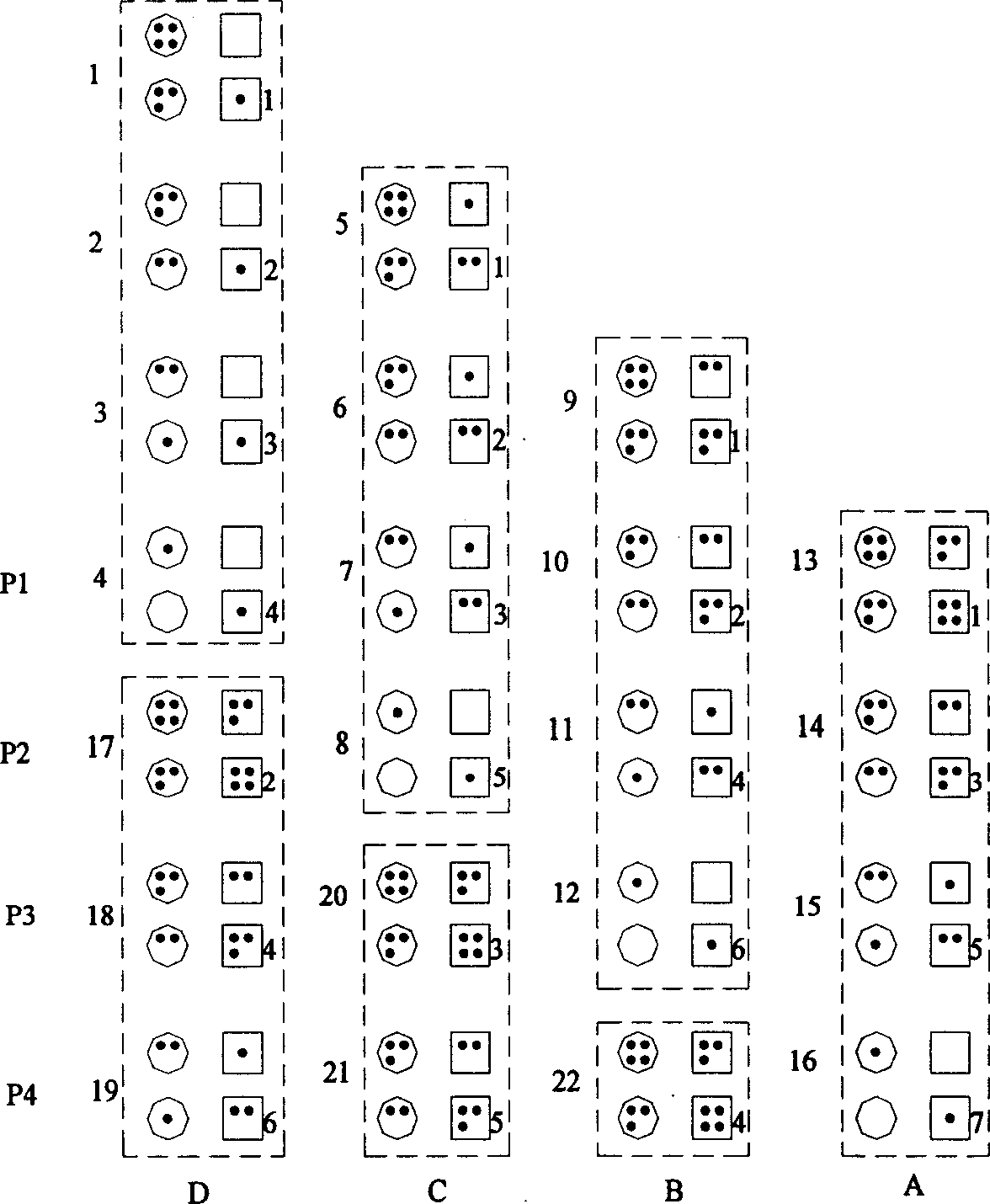

[0024] Grind the Panax notoginseng medicinal material to a particle size of 20-80 mesh, weigh 10 g each and put them into four extraction tanks A, B, C, and D, add 5-10 times the volume, 35-90% ethanol solution to D tank, The temperature rises to 35-80°C, and the stage extraction takes 20-60 minutes. Orthogonal experiments were designed and extracted according to the key points of operation. After the extraction, the extracts were combined, the volume was measured, and samples were taken for analysis of notoginseng saponin R 1 , Ginsenoside R g1 and total saponin content. The results are shown in Table 1.

[0025] Experiment number

Embodiment 2

[0027] (1) Best technology tank group countercurrent extraction

[0028] Grind the Panax notoginseng medicinal material to a particle size of 20-80 mesh, weigh 10g each and put them into four extraction tanks A, B, C, and D, add 8 times the volume of 70% ethanol solution to the D tank, and the temperature rises to 50 ℃, phase extraction for 30min. Extract by operating points. After the extraction, the extracts were combined, the volume was measured, and samples were taken for analysis of notoginseng saponin R 1 , Ginsenoside R g1 and total saponin content.

[0029] (2) Hot reflux extraction

[0030] Weigh 10 g of Panax notoginseng medicinal material granules (20-80 mesh), put them in a 250 ml flask, add 80 ml of 70% ethanol, and extract under reflux at 90°C for 3 times, 40 min each time.

[0031] (3) Ultrasonic extraction

[0032] Weigh 10 g of Panax notoginseng medicinal material granules (20-80 mesh), put them in a 250 ml Erlenmeyer flask, add 80 ml of 70% ethanol, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com