Gastric floating slow-release administrating system and its three-dimensional printing forming preparation method

A drug delivery system and gastric floating technology, applied in the field of medical drug preparation, can solve the problems of complex preparation process, many equipments, and difficulties in large-scale process, and achieve the effect of making up for prolongation, accelerating drug release, and compensating for the release route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Layer powder and binder deployment

[0033] Pass hydroxypropyl methylcellulose HPMC 4M, paracetamol, polyvinylpyrrolidone K30, and cetyl alcohol through a 200-mesh sieve respectively, and mix the powder with a particle size of less than 74 μm evenly to obtain a layered powder. Its raw material composition and content (weight parts) are as follows:

[0034] Acetaminophen 100 parts

[0035] Hydroxypropyl methylcellulose HPMC 4M 12 parts

[0036] Polyvinylpyrrolidone K30 9 parts

[0037] Cetyl alcohol 10 parts

[0038] Weigh 2 grams of ethyl cellulose (EC) powder at 5 cps, and dissolve 5 grams of polyvinylpyrrolidone K30 powder in 100 mL of 90% ethanol aqueous solution to prepare spraying adhesive 1.

[0039] Weigh 5 grams of polyvinylpyrrolidone K30 powder and dissolve it in 100 mL of 90% ethanol aqueous solution to prepare spraying adhesive 2.

Embodiment 2

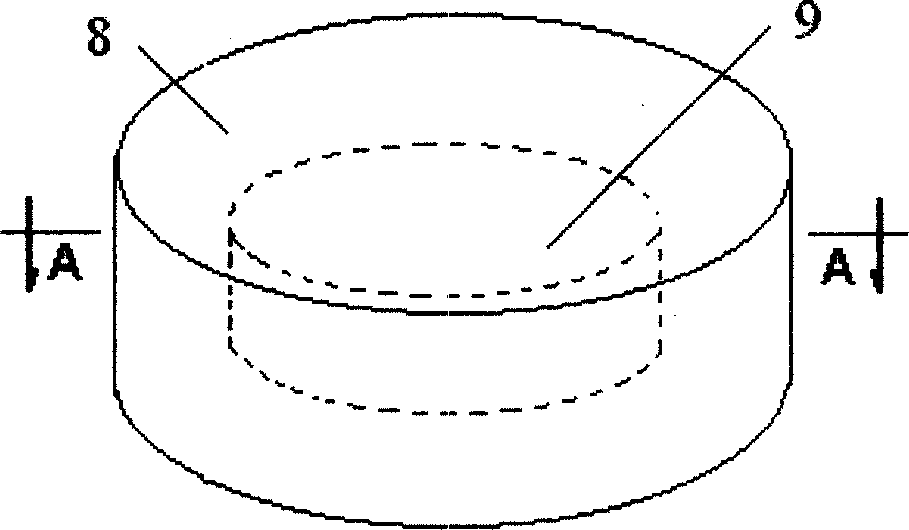

[0040] Example 2: Determining 3D printing forming parameters

[0041] Layer spraying method:

[0042] 1~10 layers Spraying the entire garden surface of Φ10mm

[0043] 11-20 layers Spray a circle with a circumference of 2mm

[0044] 21~30 layers Spraying the entire garden surface of Φ10mm

[0045] Spray forming parameters:

[0046] Layer interval time 2min

[0047] Powder layer thickness 100~200μm

[0048] Spraying rate [spraying drop volume (droplet quantity × droplet size) × spraying frequency] 4nL × 12kz

[0049] Spraying times 2 to 3 times

Embodiment 3

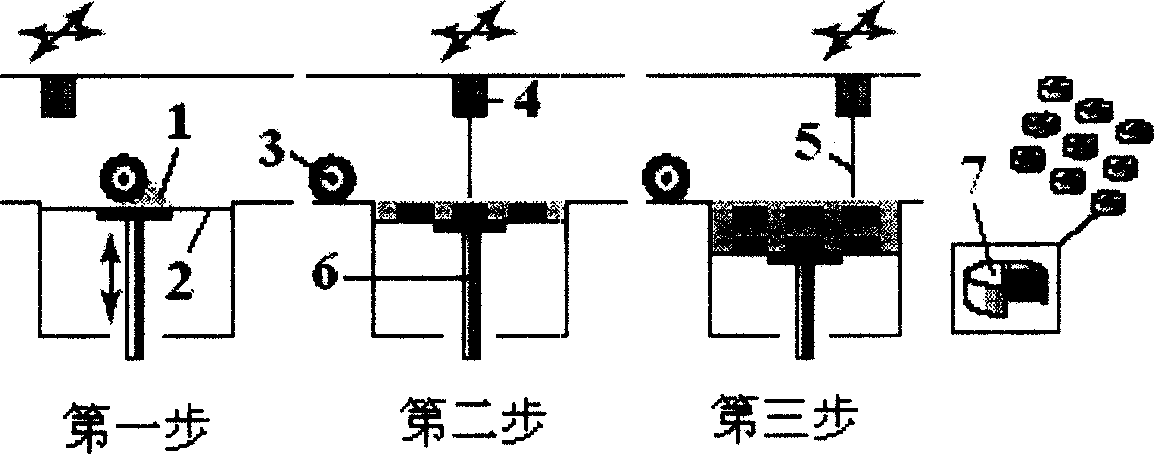

[0050] Example 3: Preparation of gastric floating sustained-release drug delivery system containing ethyl cellulose

[0051] The operation of the 3D printing system is directly controlled by the computer terminal output command: first spread a layer of mixed powder with a thickness of 200μm, spray the binder 1 for 2 times, and after 2 minutes, the piston rod drives the powder bed of the workbench to descend as a whole, and then spread another layer The mixed powder with a thickness of 200 μm is sprayed and bonded to form, so that the three-dimensional printing forming parameters determined in Example 2 are repeated continuously to obtain a gastric floating sustained and controlled release drug delivery system. Then the obtained drug delivery system is dried and depowdered to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com