Horn for environment protection digifax pulsewidth modulation vehicle

A technology for pulse width modulation and vehicle use, which is applied to sound-generating devices and instruments, and can solve problems such as short service life, high relative sound pressure level, and complex circuit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

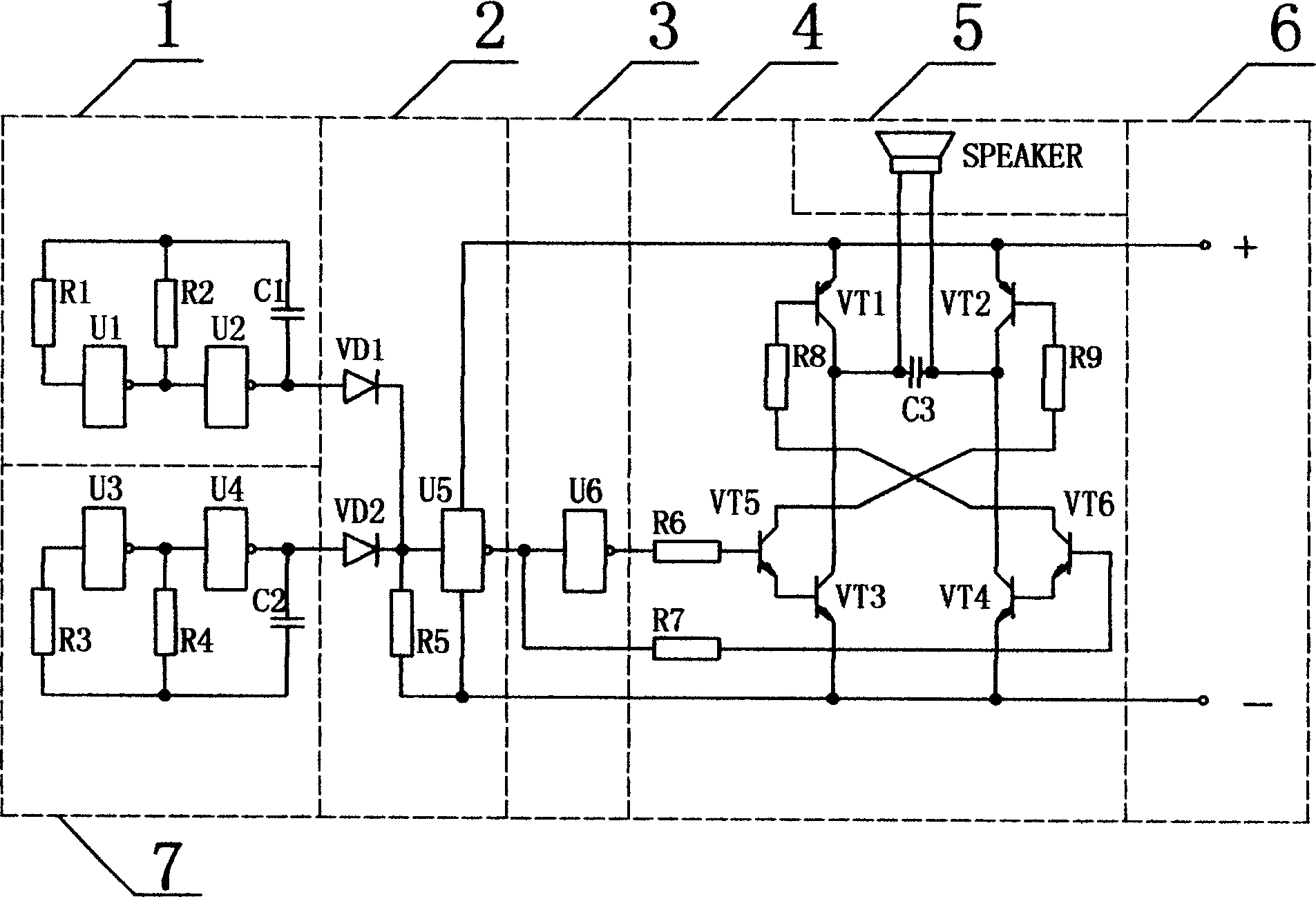

[0017] Depend on figure 1 The embodiment represented by -4, it pushes back pole plate 9, magnetic steel 10, front pole plate 11, sound film 12, horn 13, front grid 14 by oscillator 1, oscillator 7, PWM modulator 2, PWM. Oscillator 1 is composed of R1, R2, U1, U2 and C1. One end of R1, R2 and C1 is connected in parallel, U1 is connected in series between R1 and R2, and U2 is connected between R2 and C1. The oscillator 7 is composed of R3, R4, U3, U4 and C2, one end of R3, R4 and C2 is connected in parallel, U3 is connected in series between R3 and R4, and U4 is connected between R4 and C2. PWM modulator 2 is composed of VD1, VD2, R5, and U5. The positive pole of VD1 is connected to U2 and C1 of oscillator 1, the positive pole of VD2 is connected to U4 and C2 of oscillator 7, and the negative poles of VD1 and VD2 are connected to R5 and U5. connect. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com