Continuous catalyst-adding operation method for esterification reactor

An operation method and an esterification reaction technology, which are applied in the field of strong acid homogeneous catalysts in an esterification reactor, can solve problems such as accelerated corrosion, and achieve the effects of slowing down corrosion, increasing economic benefits, and prolonging the start-up period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

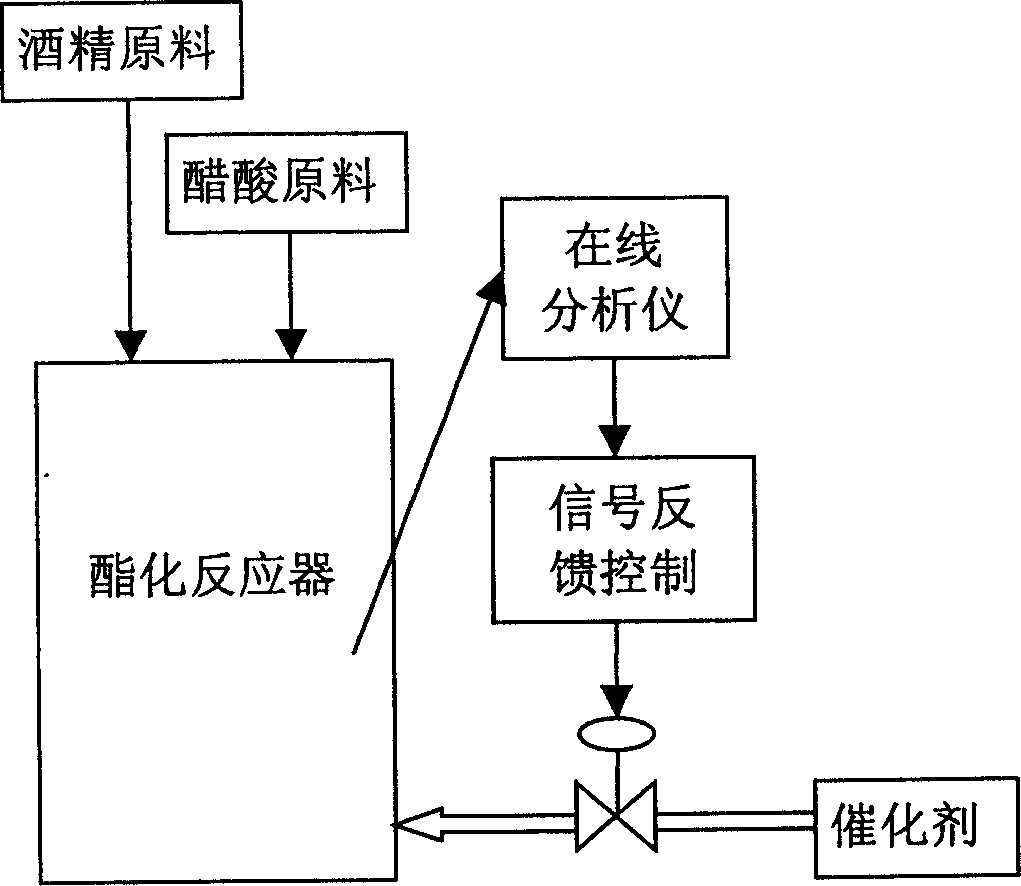

[0013] The mixed raw materials of 50% acetic acid, 45% ethanol, and 5% water are preheated to 95°C and enter the reactor in the form of a gas-liquid mixture. Internal components and heating elements arranged in a specific way are specially designed in the reactor to achieve good self-stirring Effect. Catalyst sulfuric acid is pre-added in an appropriate amount before starting up. During the operation, the catalyst is continuously added according to the catalyst concentration analyzed by the online analyzer. The reaction product is vaporized and enters the esterification tower for rectification and separation to obtain crude ester at the top of the tower.

[0014] reactor and catalyst

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com