Epitaxial wafer for semiconductor light-emitting device and semiconductor light-emitting device

A technology of light-emitting devices and semiconductors, which is applied in the direction of semiconductor devices, semiconductor lasers, laser components, etc., can solve the problems of device characteristics and reliability degradation, and achieve the effect of inhibiting and reducing diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Next, examples of the present invention will be described.

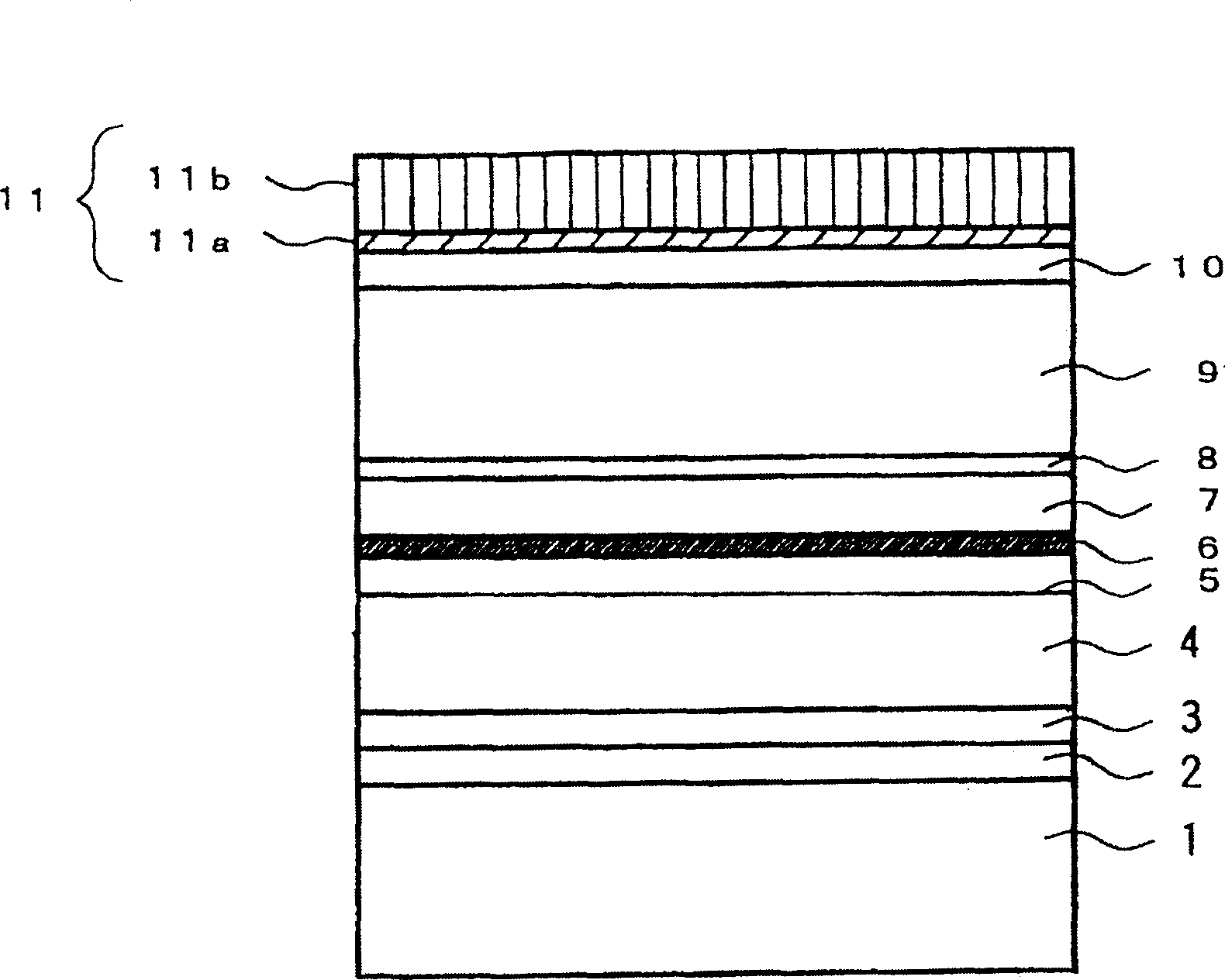

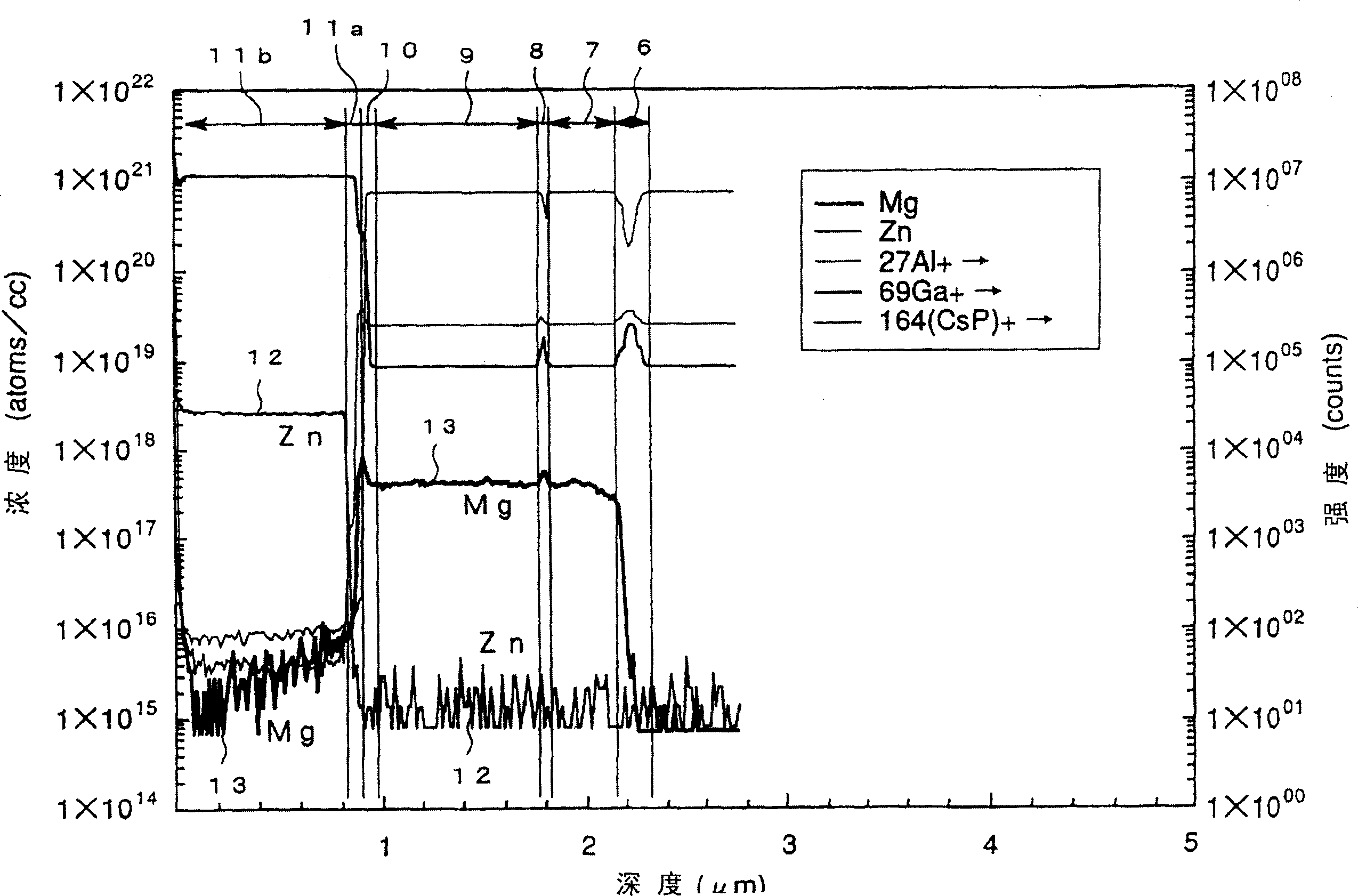

[0040] like figure 1 As shown, on an n-type substrate 1 composed of GaAs, an n-type buffer layer 2 composed of GaAs, an n-type buffer layer 3 composed of GaInP lattice-matched to it, and an n-type buffer layer 3 composed of (Al 0.7 Ga 0.3 ) 0.5 In 0.5 The n-type cladding layer 4 composed of P, on which, is grown sequentially by (Al 0.5 Ga 0.5 ) 0.5 In 0.5 An undoped guide layer 5 composed of P, an active layer 6 composed of a multi-quantum well (MQW) composed of a barrier layer and a strained GaInP well layer, and then composed of (Al 0.7 Ga 0.3 ) 0.5 In 0.5 The Mg-doped p-type first cladding layer 7 composed of P, the p-type etching stop layer 8 composed of GaInP, and the (Al 0.7 Ga 0.3 ) 0.5 In 0.5 The Mg-doped p-type second cladding layer 9 made of P, and the Mg-doped p-type intermediate layer 10 made of GaInP.

[0041] In this way, the Mg-doped p-type cladding layer (Mg-doped layer) 11a made...

Embodiment 2

[0046] In the zinc diffusion suppressing layer (Mg-doped p-type cladding layer 11a) of the present invention, the doping amount of magnesium can be freely set to some extent. Therefore, as another example, the carrier concentration of the Mg-doped p-type cladding layer (Mg-doped layer) 11a as the zinc diffusion suppressing layer is set to 4×10 18 cm -3 , the Zn-doped p-type cladding layer (layer doped with Zn) 11b is also set as 4×10 18 cm -3 To form the result, the same effect can be exerted.

Embodiment 3

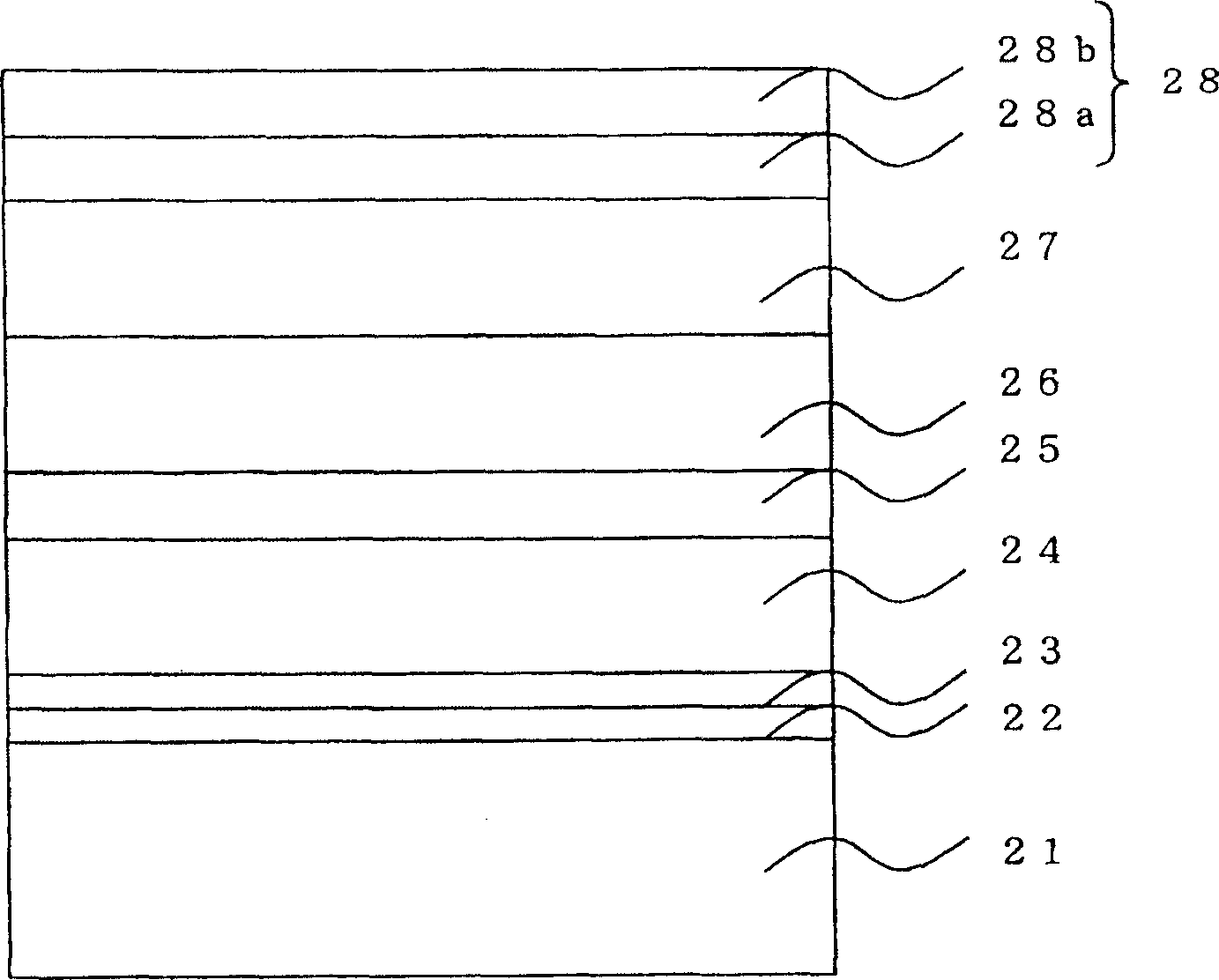

[0048] like image 3 As shown, on the n-type substrate 21 made of GaAs, the n-type buffer layer 22 made of GaAs is epitaxially grown sequentially, and the n-type buffer layer 22 made of Al 0.5 Ga 0. The n-type DBR layer 23 composed of a thin film multilayer structure of 5As and AlAs, composed of (Al 0.7 Ga 0.3 ) 0.5 In 0.5 An n-type cladding layer 24 composed of P, on which, an active layer 25 composed of a multi-quantum well (MQW) composed of a barrier layer and a strained GaInP well layer is grown sequentially, consisting of (Al 0.7 Ga 0.3 ) 0.5 In 0.5 The Mg-doped p-type cladding layer 26 made of P, and the p-type current diffusion layer 27 made of GaP.

[0049] In this way, the Mg-doped p-type cladding layer (Mg-doped layer) 28a made of GaAs and the Zn-doped p-type clad layer made of GaAs are grown sequentially on the uppermost part with the zinc diffusion suppressing layer of the present invention. Covering layer (Zn-doped layer) 28b. The thickness of the Mg-dop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com