Non-polar single crystalline A-plane nitride semiconductor wafer and preparation thereof

A technology of nitride semiconductor and nitride film, which is applied in semiconductor/solid-state device manufacturing, crystal growth, single crystal growth, etc., and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

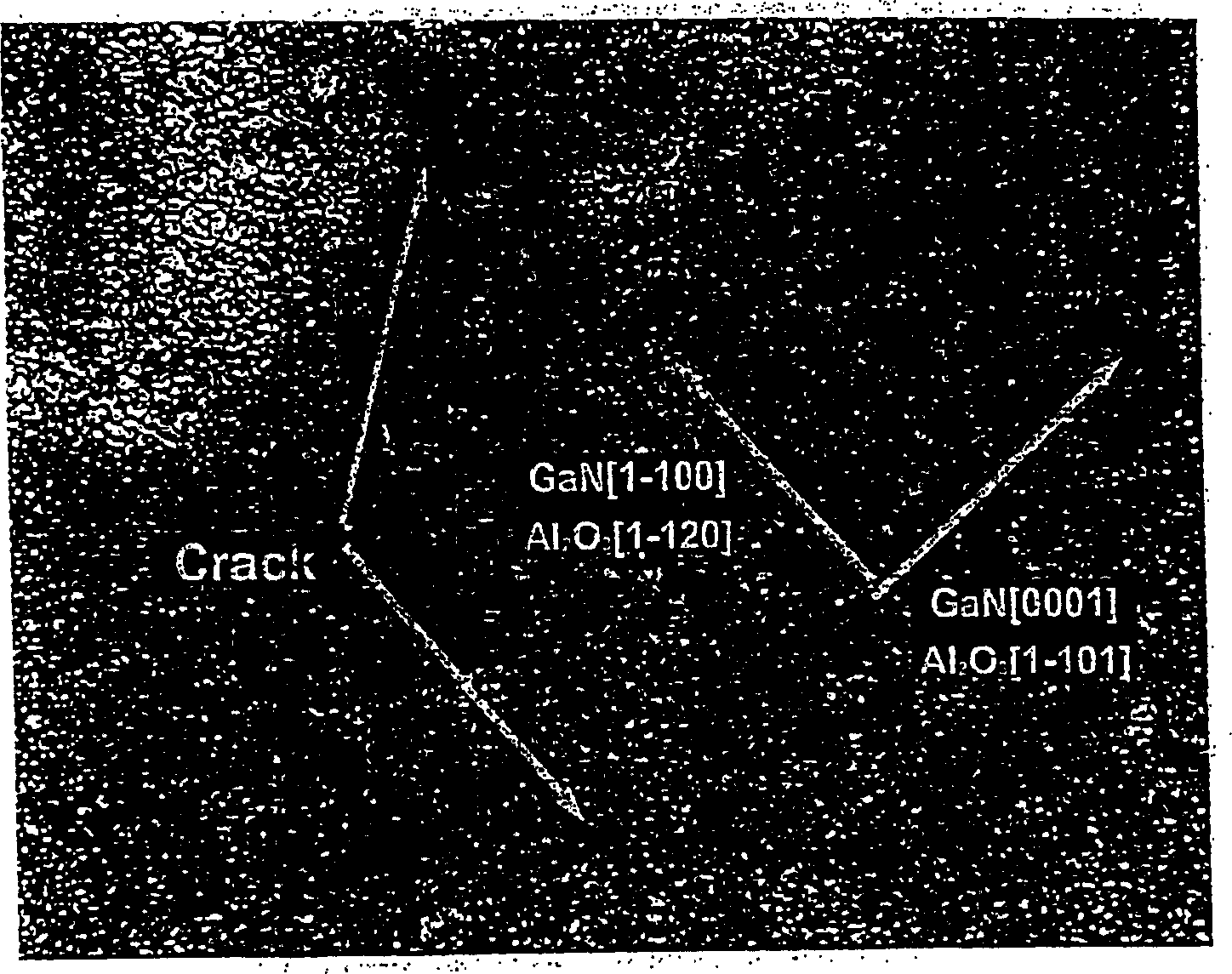

[0037] In the HVPE reactor, a single-crystal r-plane sapphire substrate with a diameter of 50.8 mm was placed, and nitriding was performed at 950 to 1100° C. with gaseous ammonia, a gas mixture of ammonia and hydrogen chloride, and gaseous ammonia in sequence.

[0038] On the nitride substrate thus obtained, a gallium nitride single crystal film was allowed to grow at a rate of 75 µm / hr by bringing gaseous gallium chloride and gaseous ammonia into contact therewith at 1000°C. Gallium chloride gas and gaseous ammonia, produced by the reaction of gallium with hydrogen chloride, are introduced through two separate inlets at a volume ratio of gaseous hydrogen chloride: gaseous ammonia of 1:6. The reactor chamber is maintained at a temperature in the range of 600 to 900°C at ambient pressure. Growth of the gallium nitride single crystal film was performed for 400 minutes to form a 500 μm thick gallium nitride semiconductor film on the substrate.

[0039] Figure 4 and 5 A photog...

example 2

[0043] Except that the volume ratio of gaseous hydrogen chloride and gaseous ammonia is in the range of 1:2-5, the steps of Example 1 are repeated to form a 500 μm thick gallium nitride semiconductor film on a sapphire substrate.

[0044] Figure 8A and 8B SEM photographs and XRD vibration curves of the surface of the thus formed a-plane GaN thick film are shown respectively. Figure 8B The XRD vibrational curve of the a-plane nitride film has a FWHM value of 342 arc seconds, which is the smallest value among the FWHM values reported so far, which indicates that the crystallinity of the film is significantly improved.

[0045] As described above, according to the method of the present invention, a high-quality nonpolar single-crystal a-face nitride semiconductor wafer without voids, warpage, or cracks can be produced quickly and efficiently, and it can be advantageously used for LED manufacturing in the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com