Optimized treatment method for ceramic colorant and ceramic colorant therefrom

A ceramic pigment and processing method technology, applied in the field of ceramic technology, can solve the problems of large amount of pigment usage, long time required, energy consumption, etc., and achieve the effects of shortening firing time, reducing usage, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

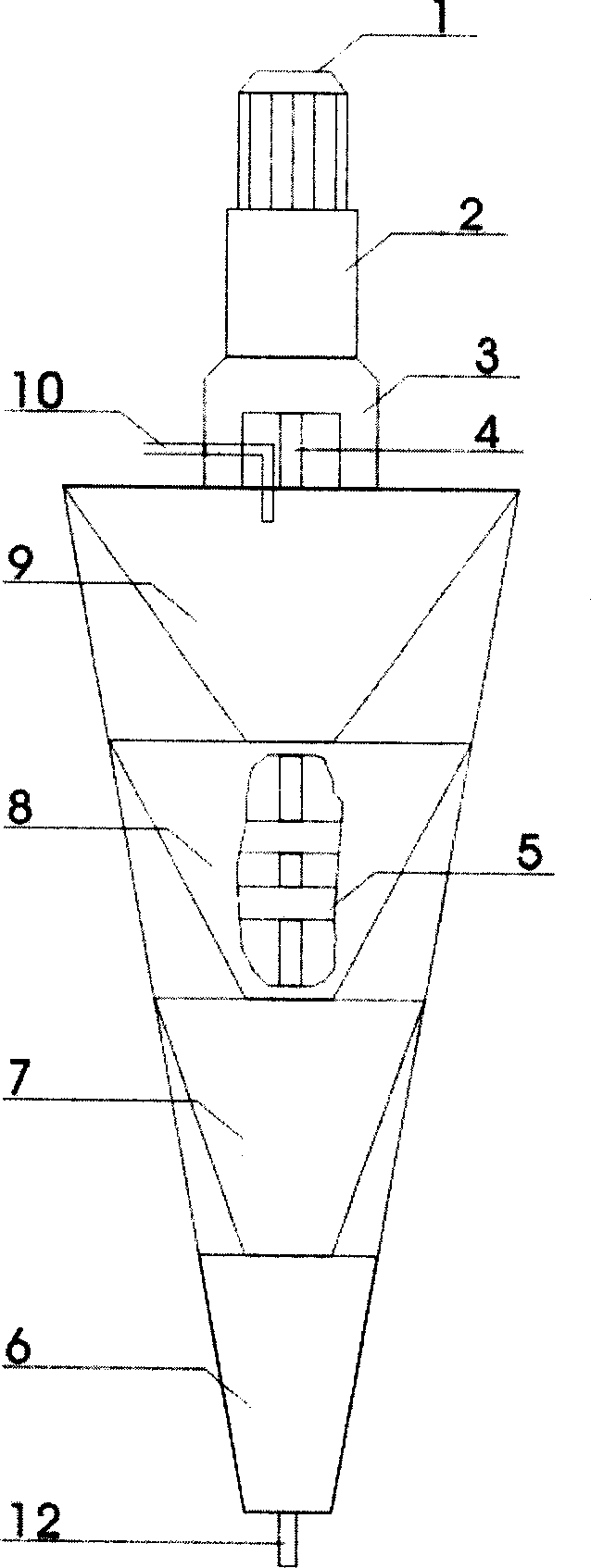

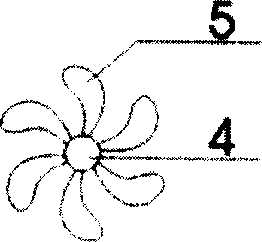

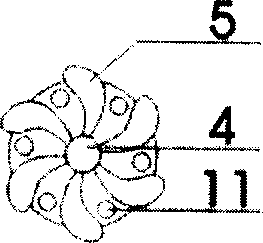

Image

Examples

experiment example

[0032] 1) Ceramic colorant (vanadium zirconium yellow produced in Guangdong, particle size is D90<30 μ (D90 represents the diameter of 90% of the particles in the sample), 1 kg) is added with water to make a mixed slurry with a solid content of 65%;

[0033] 2) Use the following equipment to conduct ultra-fine treatment comparison experiments on the above slurry, and use a laser particle size analyzer (JL1001, produced by Dandong Instrument Research Institute) to measure the particle size distribution of the refined powder to indicate the ultra-fine effect of the powder ;

[0034] A. Ball mill (QMA-300-500 type, produced by Liuzhou Weilin Superhard Material Equipment Factory): one-time feeding, continuous start-up and grinding for 4 hours, stop, take out materials, take samples, measure particle size, D90<20μm.

[0035] B. Stirring mill (AXM-8 type, Wuxi Haibo Drying Machinery Equipment Factory): one-time feeding, continuous start-up and grinding for 4 hours, stop, take out th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com