Method for heating liquid in an electric kettle

A technology for electric kettles and water heating, which is applied in the direction of boiling water appliances, applications, kitchen utensils, etc., to reduce the risk of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

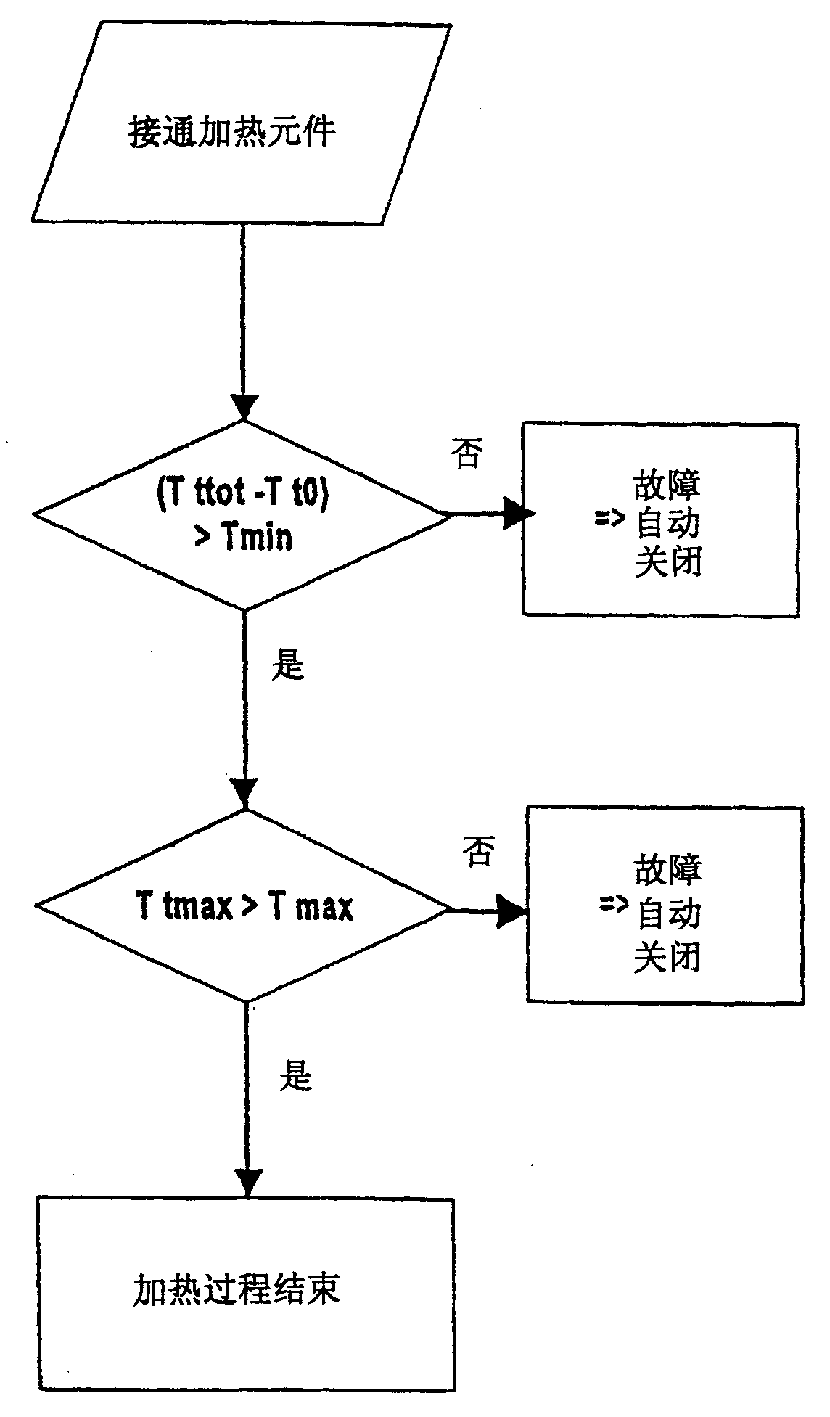

[0023] The following is for reference figure 1 An exemplary illustration of a flow chart of FIG. 1 , illustrating an advantageous embodiment of regulating the heating process of an electric kettle according to the present invention. The electric kettle includes an electric heating element with an electronic regulator (not shown) that registers the temperature and heating time via sensors. The regulator also includes non-volatile electronic memory (not shown) in which preset characteristic data is stored for validating sensor information.

[0024] In this embodiment, the following characteristic data are stored in the electronic memory of the regulator:

[0025] 1. Time t tot ; After the heating element is switched on, at a defined time interval t tot -t 0 Finally, it must be possible to record temperature increments even when the kettle is filled with the maximum amount of water. If not, it could be for one of two reasons. Either the heating element is faulty, or the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com