Preparation method of stable water-soluble niobium and tantalum precursor and application thereof

A water-soluble, precursor technology, applied in chemical instruments and methods, niobium compounds, tantalum compounds, etc., can solve problems such as deterioration of photoelectric properties, short service life, and restrictions on the commercial application of precursor systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

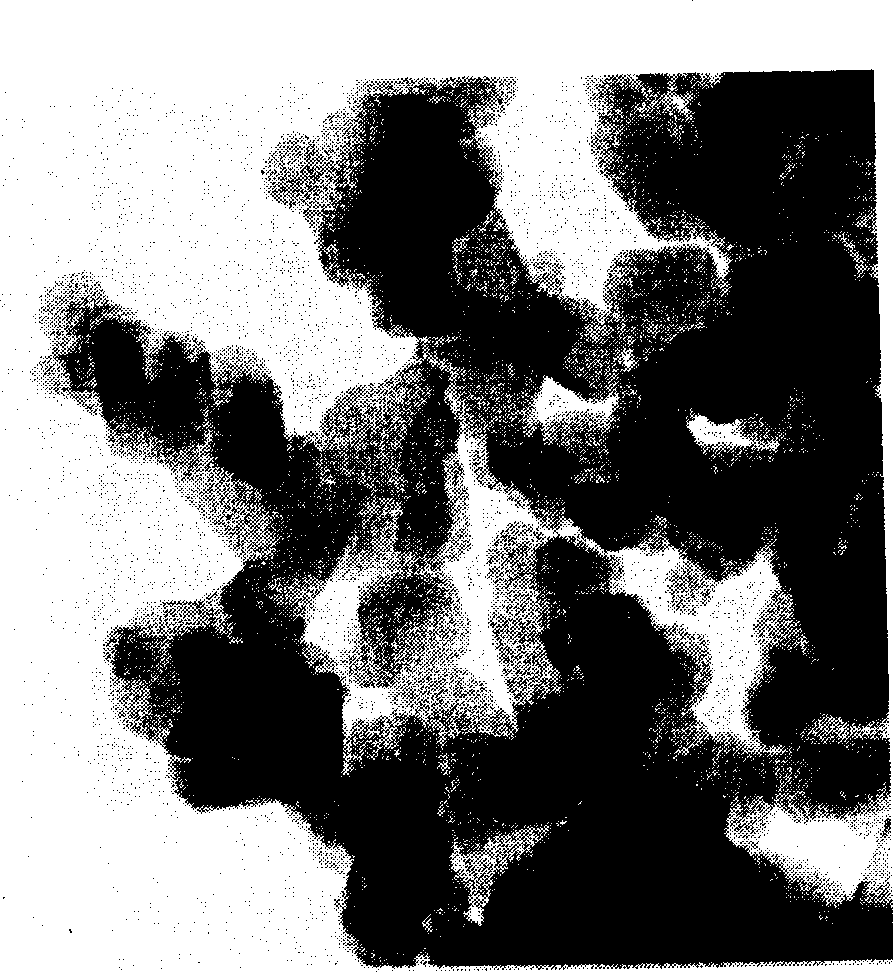

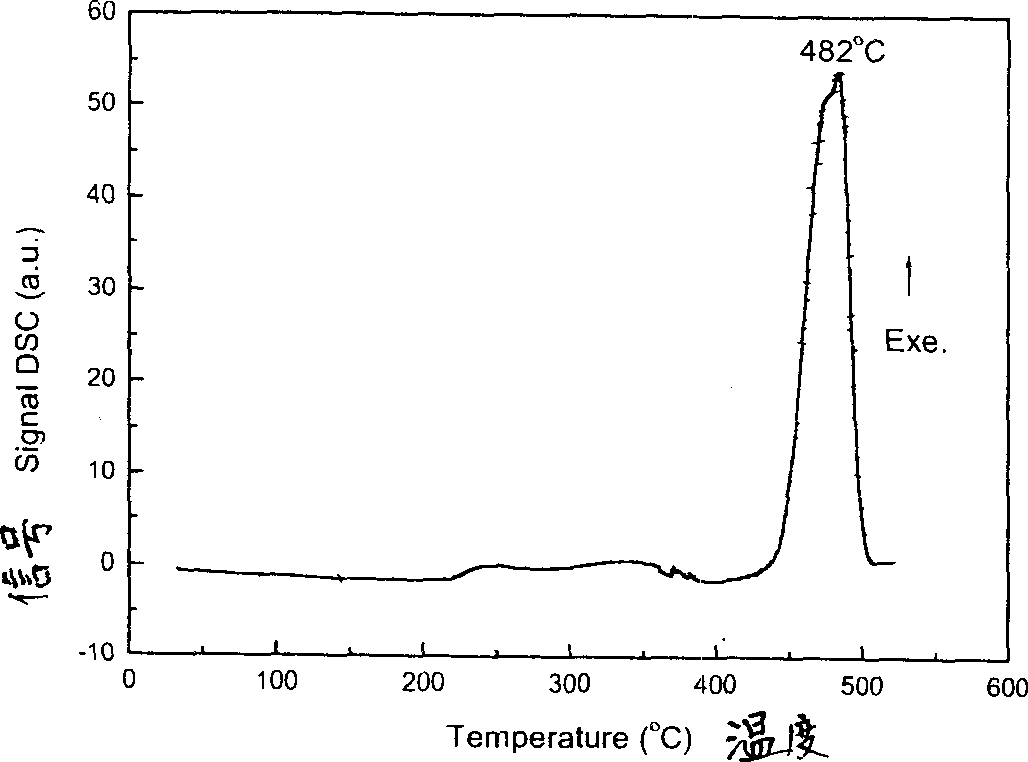

Image

Examples

Embodiment Construction

[0014] 1, the embodiment of the precursor synthesis method of water-soluble niobium:

[0015] Synthetic raw materials: niobium pentoxide (analytical pure, 99.5%), potassium hydroxide or sodium hydroxide (analytical pure), nitric acid (analytical pure), citric acid (analytical pure).

[0016] The synthesis route of water-soluble niobium precursor: mix and grind niobium pentoxide and potassium hydroxide or sodium hydroxide in a molar ratio of 1: (2~20), put them into a corundum crucible, and burn them at 400-550°C for reaction 2 -4 hours, such as burning at 450°C for 2.5-3 hours to obtain a melt of potassium niobate. Dissolve the melt in deionized water, add an appropriate amount of acetic acid to the filtered clear liquid, and a white niobic acid precipitate (Nb 2 o 5 ·nH 2 0), then adjust the pH value to make the solution acidic (PH<4), and the niobium in the solution is completely precipitated in the form of niobic acid. After filtering, the white precipitate was washed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com