Organic-inorganic substances compound membrane and its preparation method

An inorganic composite membrane and organic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as narrow application range and complicated preparation process, and achieve wide application range, good repeatability, and preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

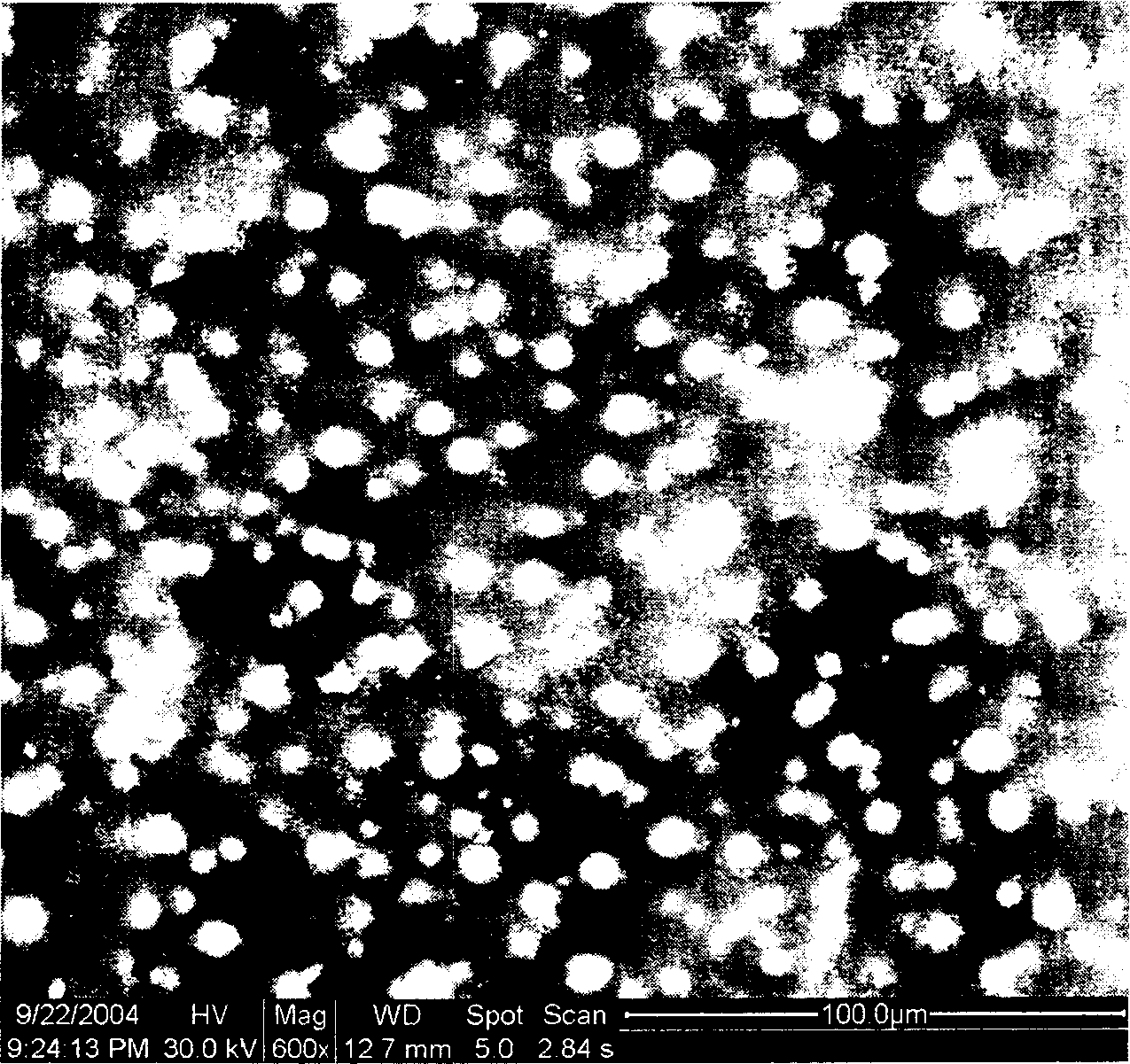

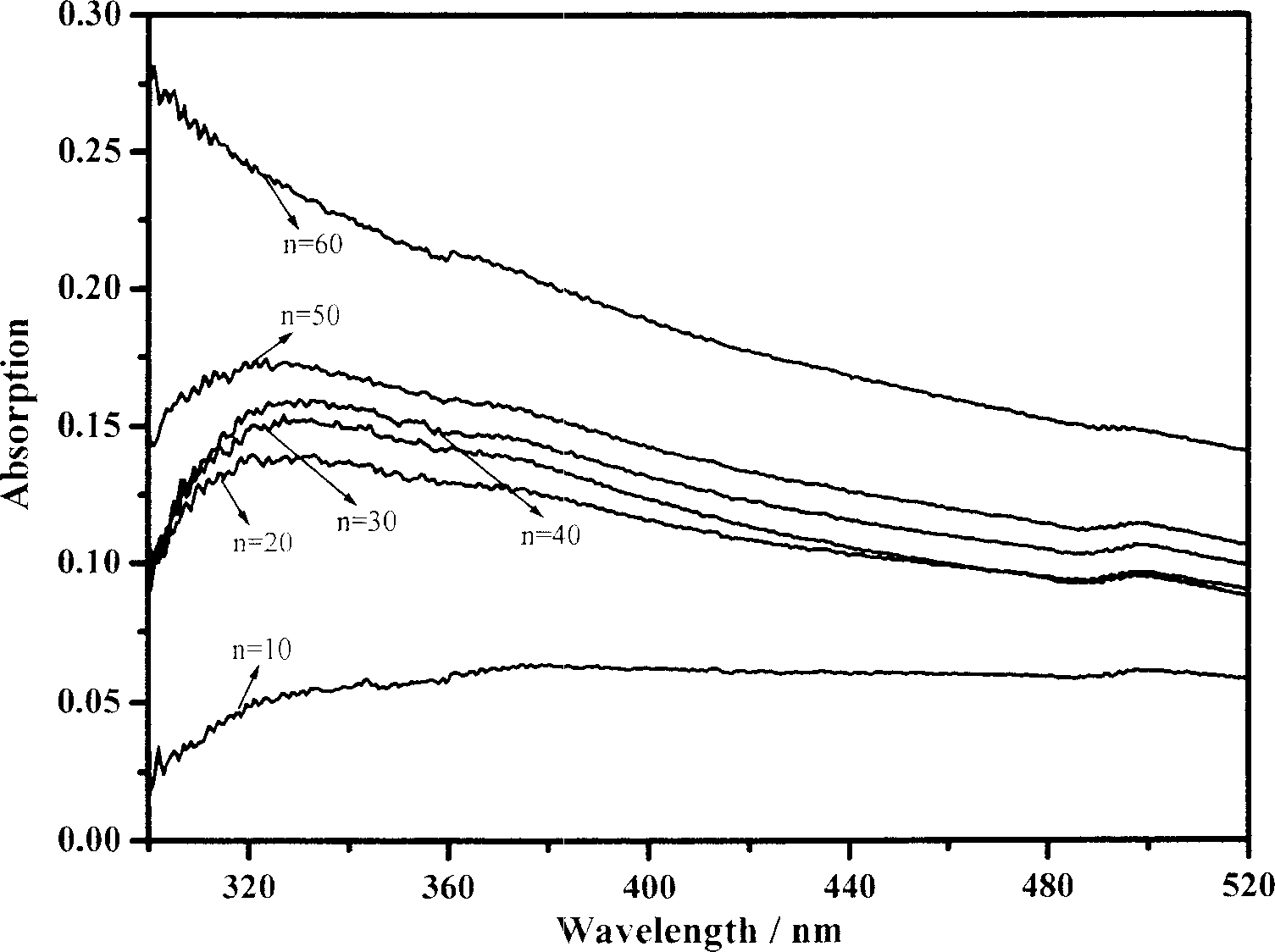

[0016] Dissolving 10-100g of montmorillonite in 1L of deionized water, filtering the suspension after ultrasonic dispersion for a certain period of time, and then diluting the obtained clear liquid to 0.1wt%-0.5wt% as anion solution. An aqueous solution of polydipropylene dimethyl ammonium chloride (PDADMAC) with a monomer concentration of 0.005-0.05M was prepared as a cationic solution. After immersing the plasma-treated negatively charged polyacrylonitrile / polyethylene terephthalate support (PAN / PET) in high-purity water for about 1 hour, it is first immersed in a cationic solution for 1 to 30 minutes. Form a positively charged film layer on the surface, then take it out and rinse it with water for 1-10 minutes to wash away the polyions and small molecule electrolyte ions adhering to the surface, and directly immerse in the anion solution for 1-30 minutes without drying to form a negatively charged film layer. Then wash with water for 1 to 10 minutes, and complete the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com