Method for processing beam, laser irradiating apparatus and method for manufacturing semiconductor device

A technology of semiconductors and lasers, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, laser components, etc., to achieve the effects of reduced manufacturing costs, high working characteristics, and improved energy distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

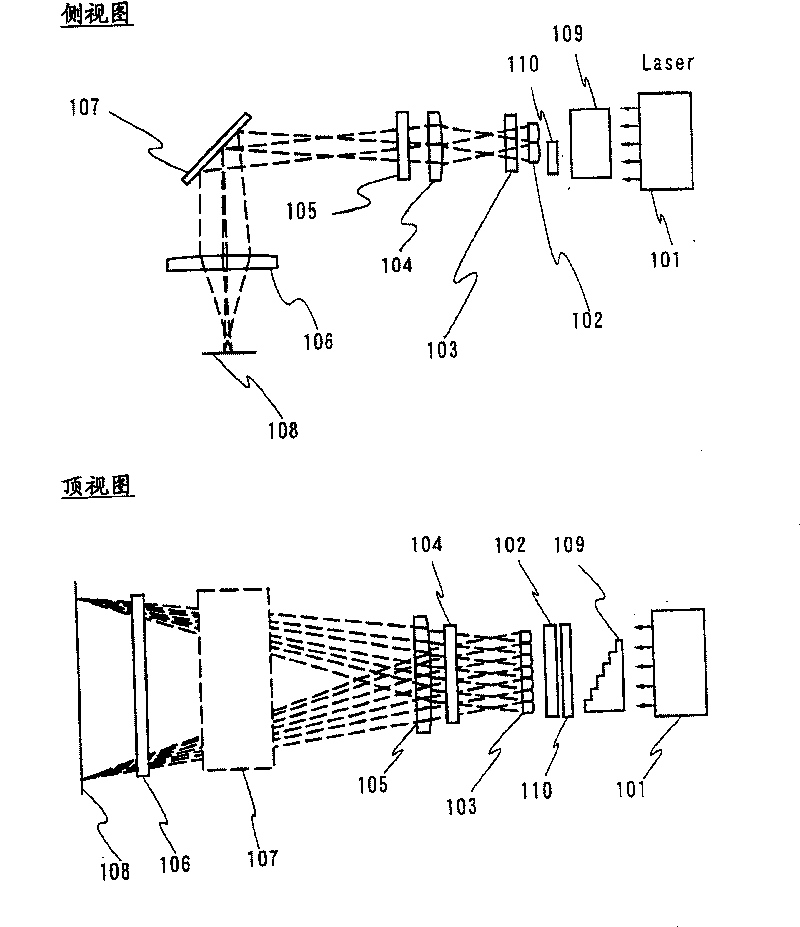

Embodiment 1

[0073] A first embodiment of the present invention will be described below with respect to a manufacturing process of a semiconductor device in which an amorphous silicon film is formed on a glass substrate and crystallized by the laser irradiation method of the present invention.

[0074] First, an example of a method of forming an amorphous silicon film will be described. A 5 inch square Corning 1737 substrate was first cleaned to remove foreign particles on the substrate surface. Then, a 100 nm-thick silicon nitride oxide film and a 55 nm-thick amorphous silicon film were formed on the substrate by a plasma CVD apparatus. The silicon oxynitride film referred to in this specification is an insulating material film represented by SiOxNy, that is, an insulating film containing silicon, oxygen, and nitrogen in predetermined proportions. Amorphous silicon films may contain a considerable amount of hydrogen. In this case, the laser resistance of the amorphous silicon film is im...

Embodiment 2

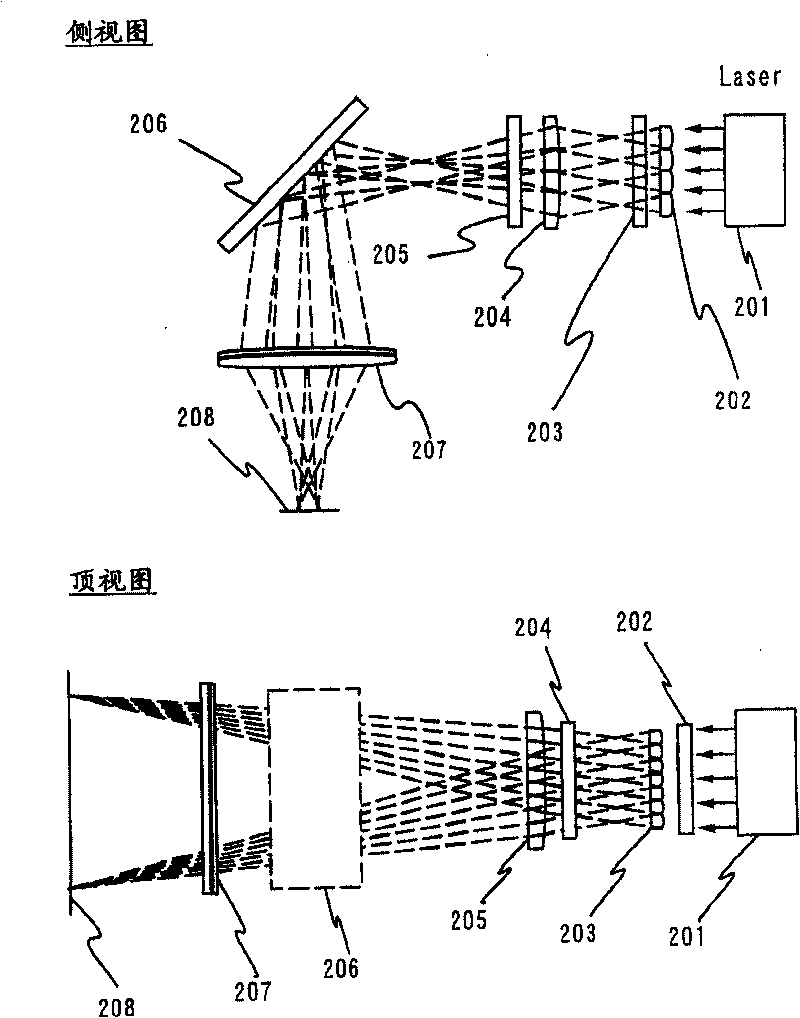

[0086]Next, a second embodiment of the present invention will be described with respect to irradiating a semiconductor polycrystalline film with a line beam to perform an annealing process.

[0087] First, a method of forming a polycrystalline semiconductor will be described. A 5 inch Corning 1737 substrate was first cleaned to remove foreign particles from the substrate surface. Then, a 100nm-thick silicon nitride oxide film and a 55nm-thick amorphous silicon film were formed on the substrate by a plasma CVD device. The silicon oxynitride film referred to in this specification is an insulating material film represented by SiOxNy, that is, an insulating film containing silicon, oxygen, and nitrogen in predetermined proportions. Next, the amorphous silicon film is processed by a method such as that described in Japanese Patent Application Laid-Open No. Hei 7-183540. That is, an aqueous solution of nickel acetate (5 ppm by weight, 5 ml in volume) was applied to the surface of ...

Embodiment 3

[0091] see Figure 5 , shows an example of a laser irradiation device for mass production in the third embodiment. Figure 5 is a top view of the laser irradiation device.

[0092] The substrate is transported from the load / unload chamber 1501 using the robot arm 1503 for transport installed in the transport chamber 1502 . First, after the substrate is positioned in the alignment chamber 1504, it is transported to the preheating chamber 1505. The temperature of the substrate is then heated in advance to a desired temperature, for example about 300° C., using a heater such as an infrared lamp. After that, the substrate is fixedly placed in the laser irradiation chamber 507 passing through the gate valve 1506 . Then the gate valve 1506 is closed, and the temperature of the substrate is increased to compensate for the lack of energy of the laser beam. Especially in cases where processing large area substrates requires extended line beam lengths, the laser energy can be contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com