Method for keeping output of liquid and gas fuel at constant pressure

A liquid fuel and gaseous fuel technology, which is applied in the direction of combustion method, liquid fuel supply/distribution, etc., can solve the problems of easy leakage of gaseous fuel, environmental pollution, and uneconomic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

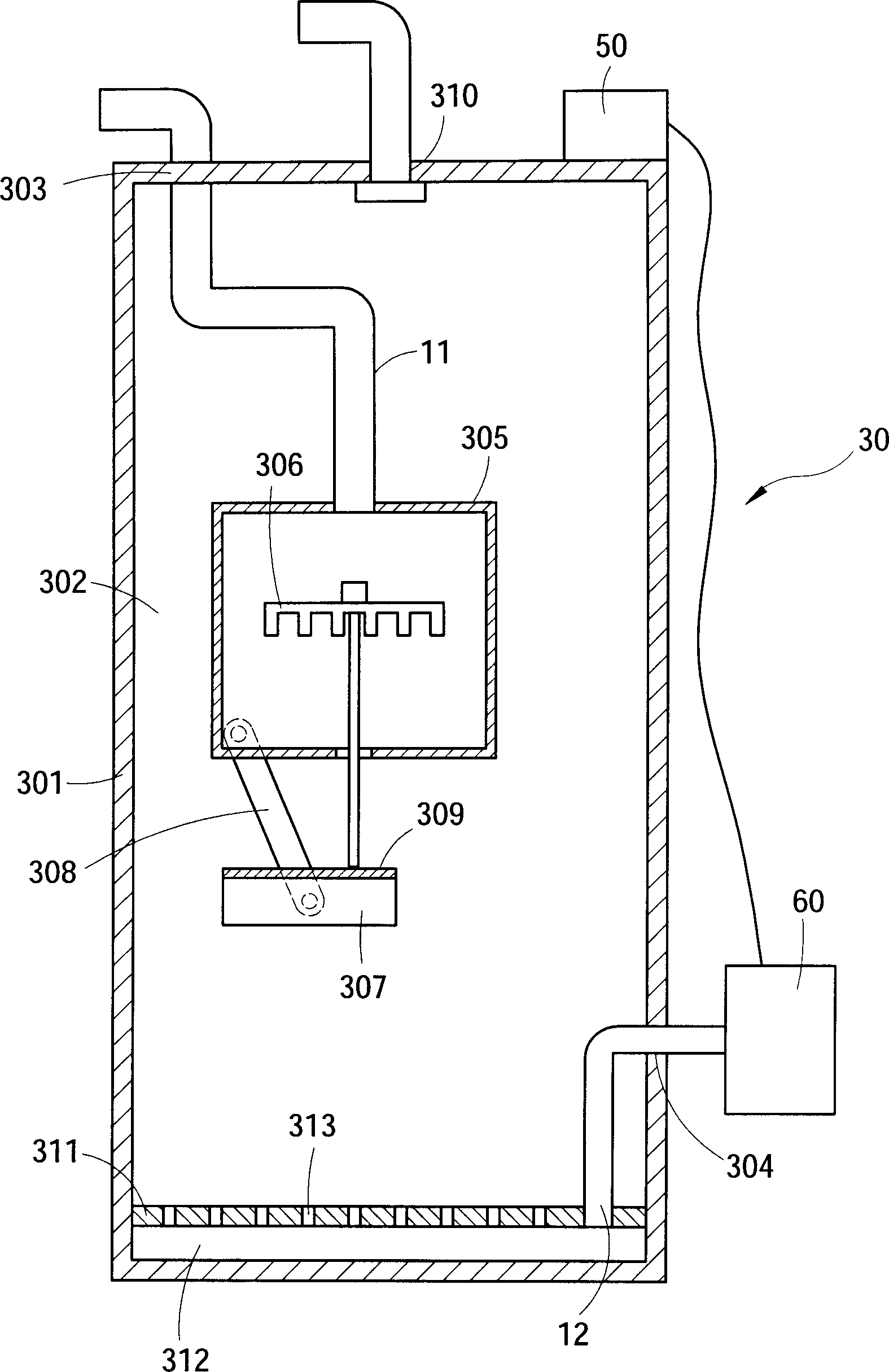

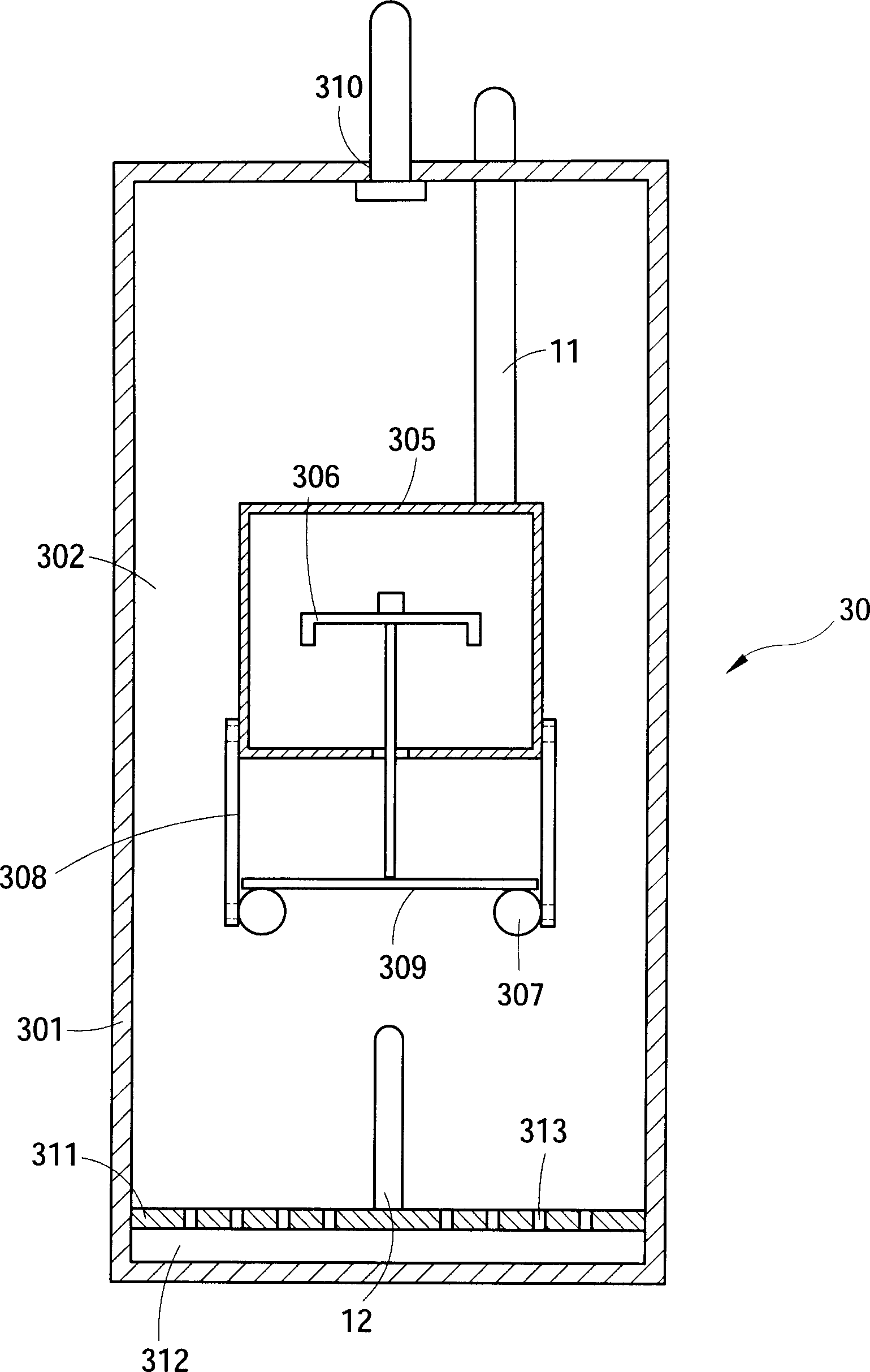

[0023] Relevant detailed description and technical contents of the present invention are as follows now in conjunction with the accompanying drawings:

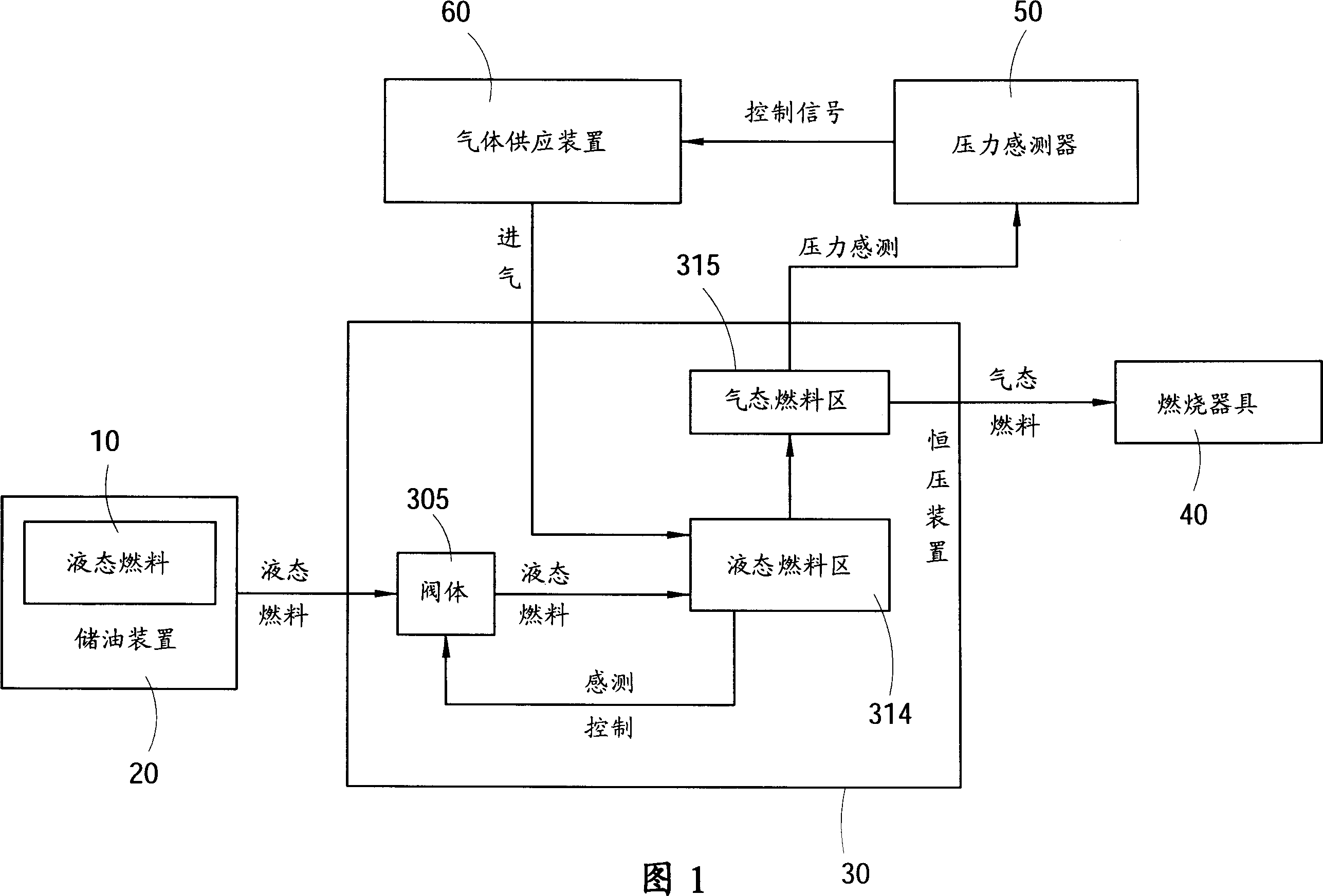

[0024] Please refer to Fig. 1, which is a schematic diagram of the program according to the present invention, as shown in the figure, it includes: an oil storage device 20, which is used for a kind of liquid fuel 10 to be input and accommodated therein, and the oil storage device 20 passes through a valve When the body 305 is opened, the liquid fuel 10 in the oil storage device 20 is output to a constant pressure device 30, and reaches a preset liquid level, and a liquid fuel zone 314 and a liquid fuel area 314 are defined in the constant pressure device 30 according to the liquid level. A gaseous fuel area 315, so that the gas supply device 60 can input gas to the liquid fuel area 314 of the constant pressure device 30 to be gasified into a gaseous fuel, and then output the gaseous fuel to a burner 40 such as a gas stove for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com