Roller trio skew rolling method for cold perforating and cold chambering ingot

An ingot casting and cross-rolling technology, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of troublesome equipment adjustment, poor economy, and poor surface quality of rolled pieces, so as to save equipment investment, energy consumption, and metal The effect of low deformation resistance and dense metal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

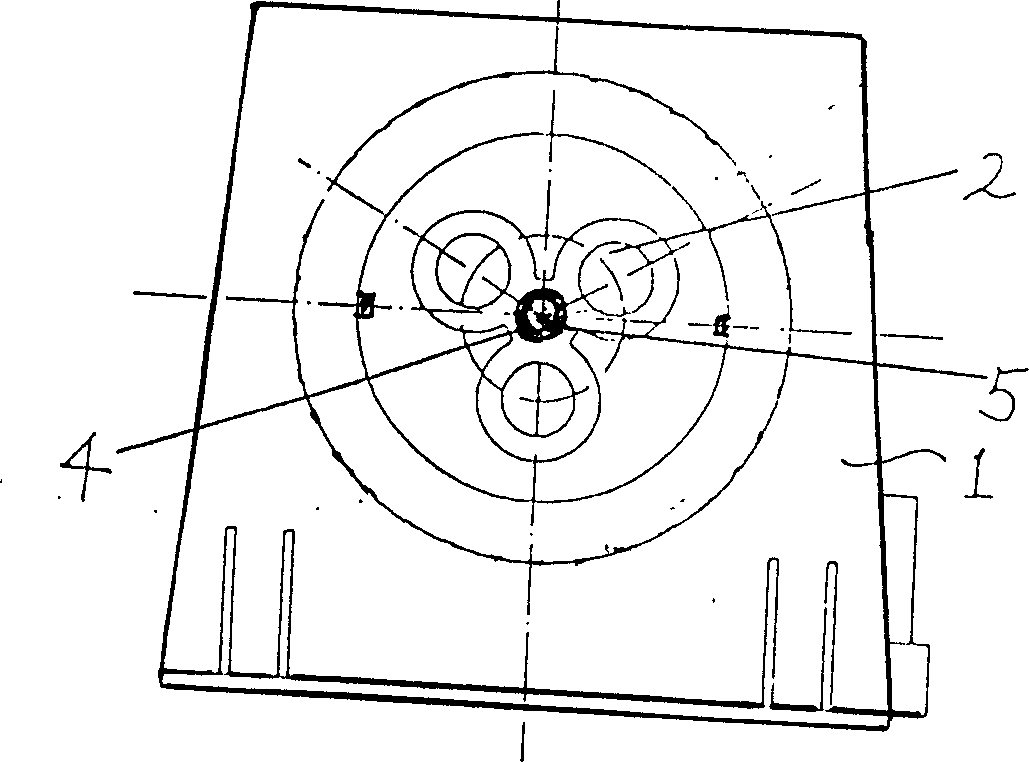

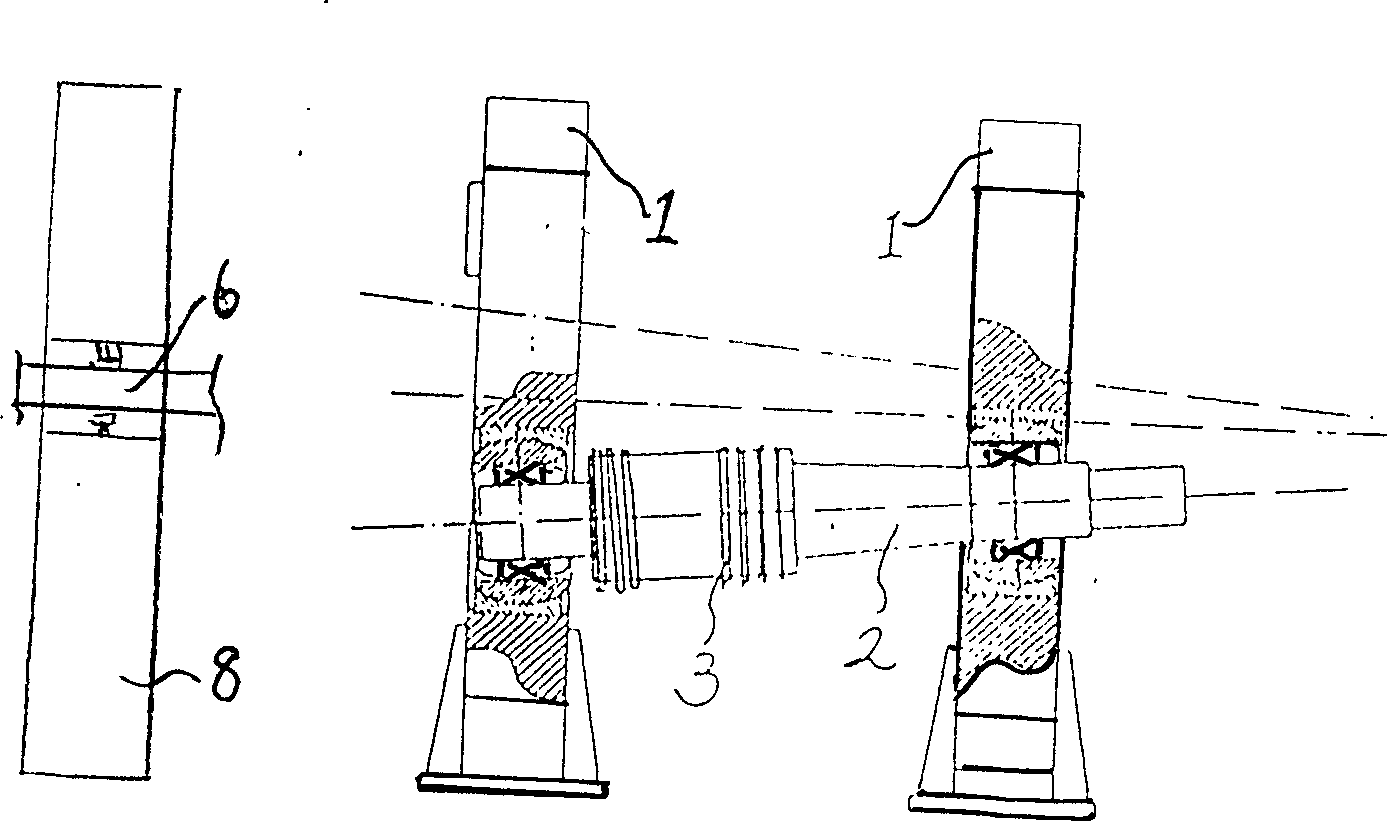

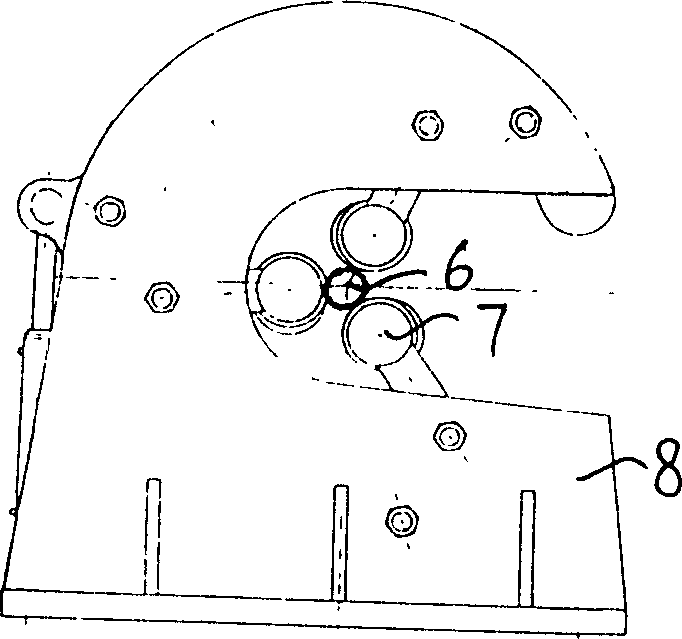

[0013] A three-roll cross-rolling method for cold piercing and cold-expanding of cast ingots. The three-roll cross-rolling mill is provided with multiple grooves and protruding rings 3 on the surface of three rolls 2 arranged at equal angles along the circumference, so that the three rolls 2 A large deformation zone is formed between them, and the surfaces of the concave and protruding rings 3 are smooth. Send the billet 4 to be processed to the large deformation zone between the three rolls for rolling, and at the same time send the plug 5 of the plug mechanism to the processing section; the three rolls rotate in the same direction, driving the rolled piece to rotate in the opposite direction, and simultaneously Axial advance produces spiral motion. The rolled piece is pressed down one by one by three rolls in the large deformation zone. Every time the rolled piece comes into contact with the rolls, it undergoes a processing deformation. The unit reduction is not large, but A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com