Automatic power and temp. controller for pumping laser

A temperature control device and automatic power control technology, applied in laser cooling devices, temperature control, lasers, etc., can solve the problems of rising cost, low efficiency, large heat generation, etc., to reduce power consumption and volume, facilitate debugging, and achieve accurate control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

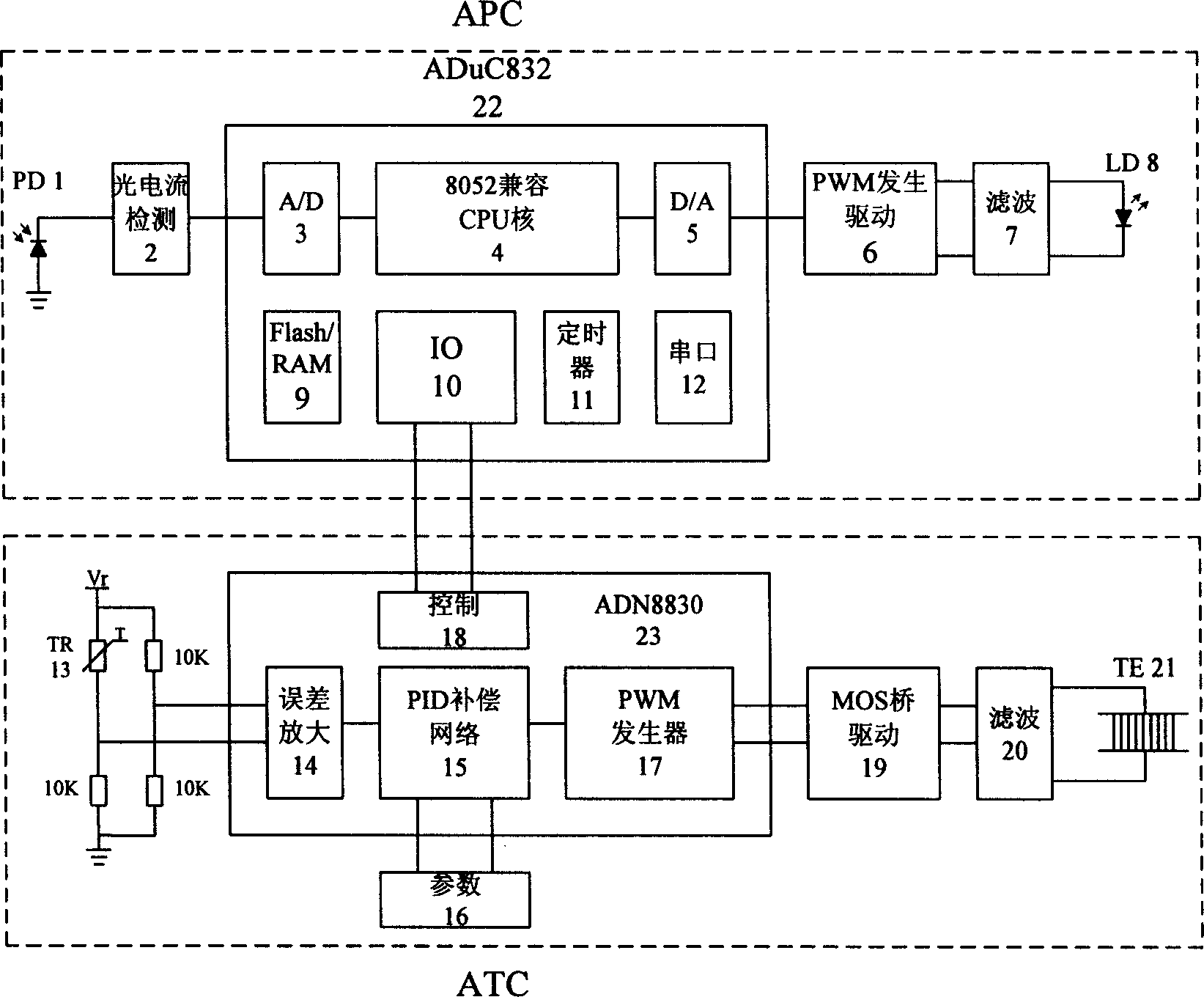

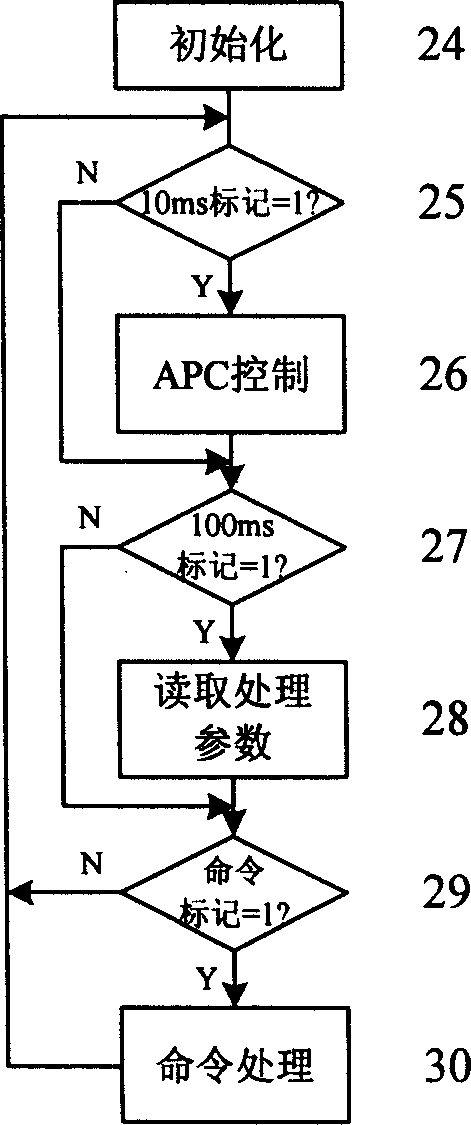

[0017] The overall block diagram of the preferred embodiment of the automatic power and temperature control device of the pump laser of the present invention is as follows figure 1 shown.

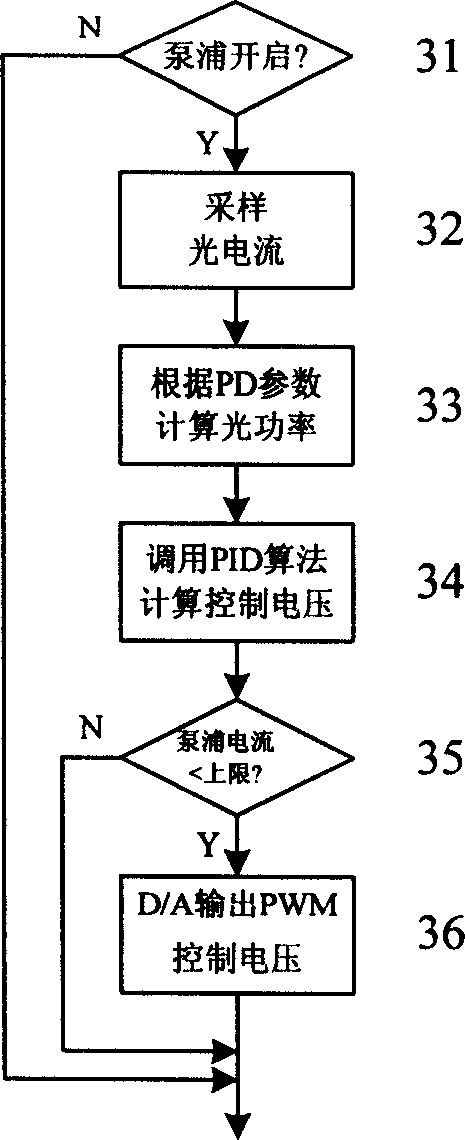

[0018] figure 1 The upper part is the APC circuit, which is composed of photocurrent detection 2, ADμC832 microcontroller 22, PWM generation and driving circuit 6. PD1 converts the pumped backlight signal into a photocurrent proportional to the pump power, which is converted into a voltage signal by the photocurrent detection circuit 2, and the A / D 3 inside the microcontroller samples the voltage signal and converts it into optical power, which is the same as the preset The pump power is compared, and the PID algorithm is called to calculate the error voltage. The D / A 5 outputs the error voltage to control the external PWM generation and drive circuit 6, and drives the pump laser LD 8 after filtering 7.

[0019] There are 8 channels of 12-bit A / D 3 and 2 channels of 12-bit D / A 5 inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com