High oxidizing filtering system

A filtration system and advanced technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of refractory degradation, no further oxidation, etc., to extend the backwash cycle , The effect of suppressing the phenomenon of concentration polarization and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

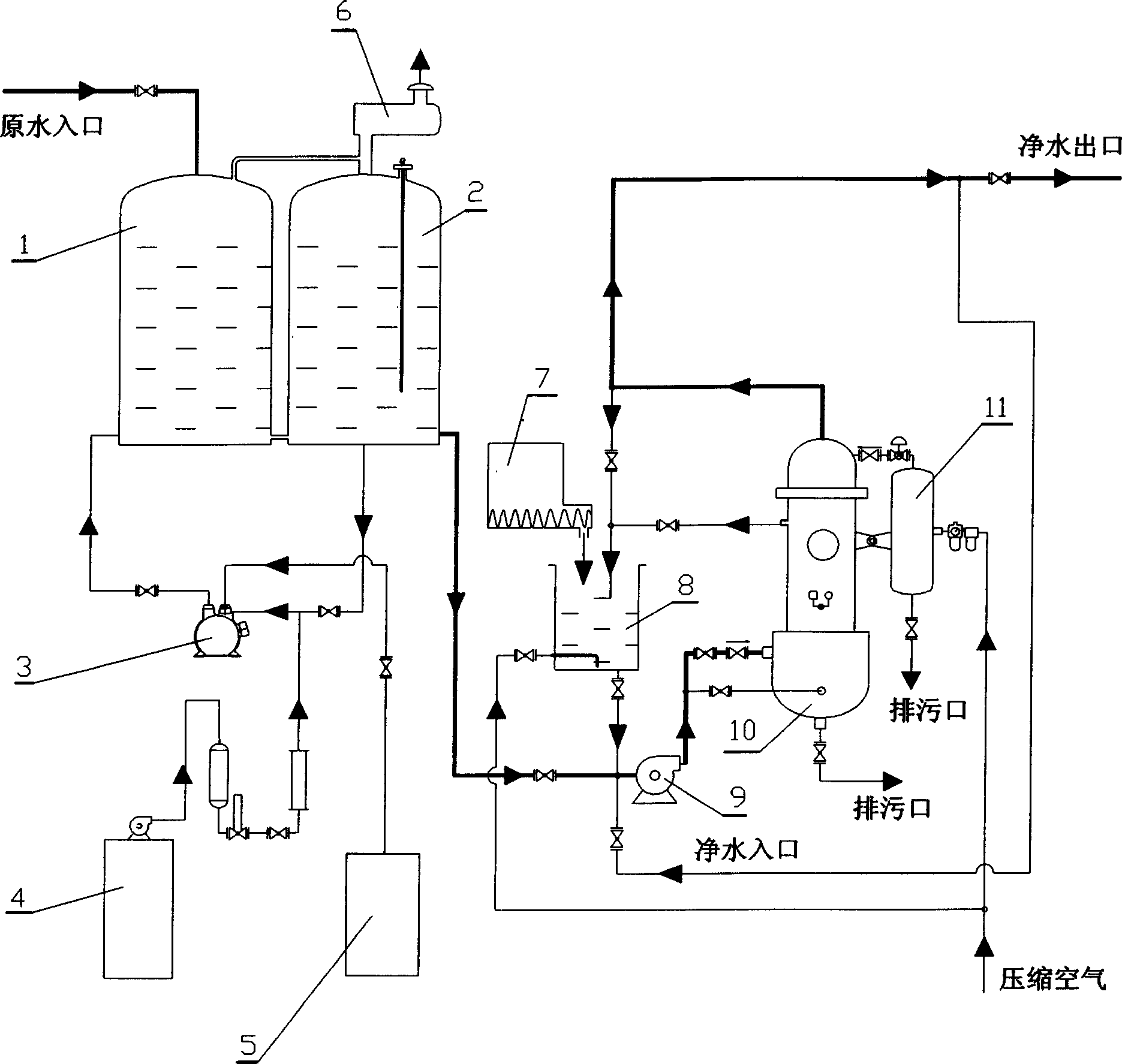

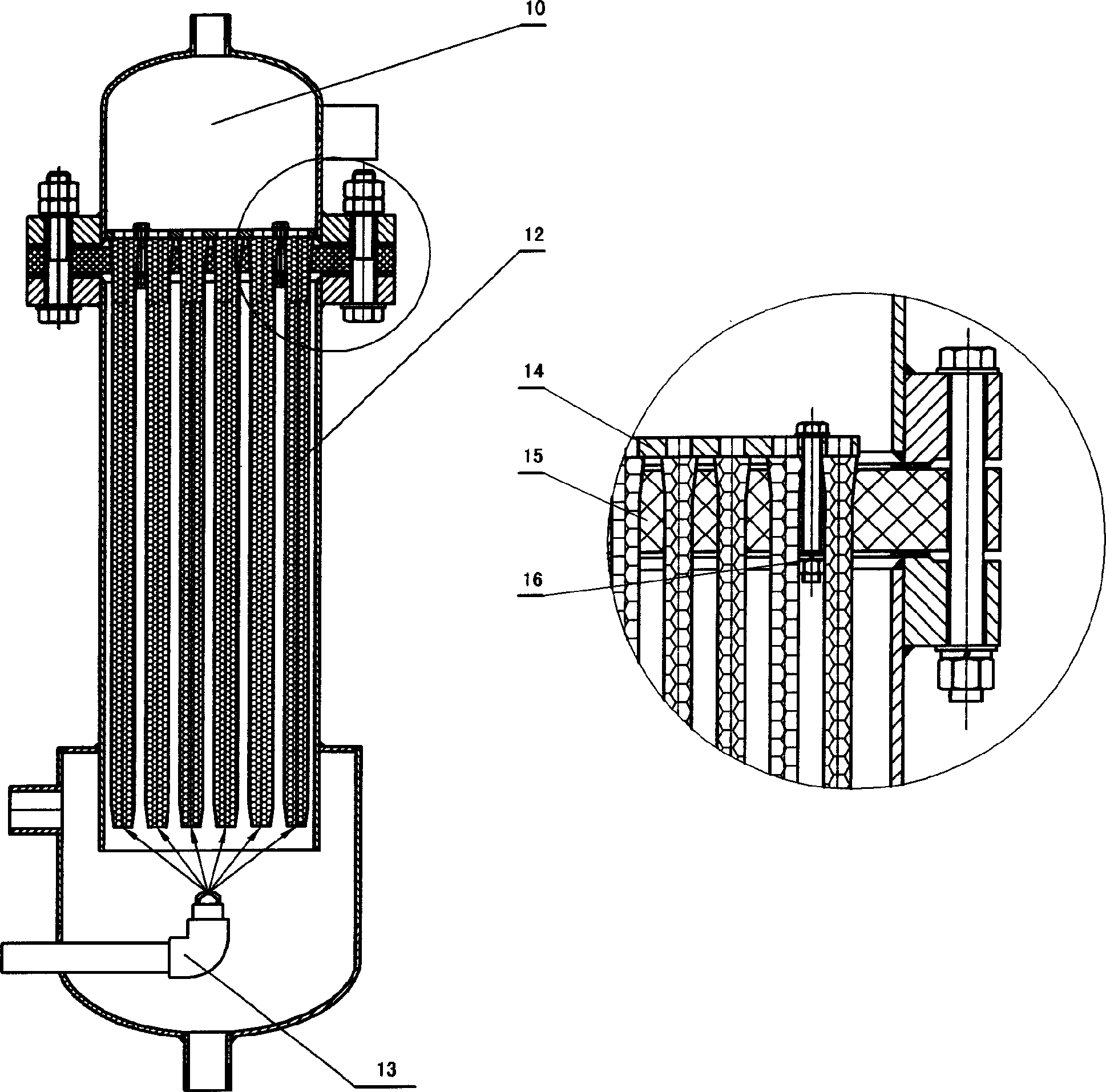

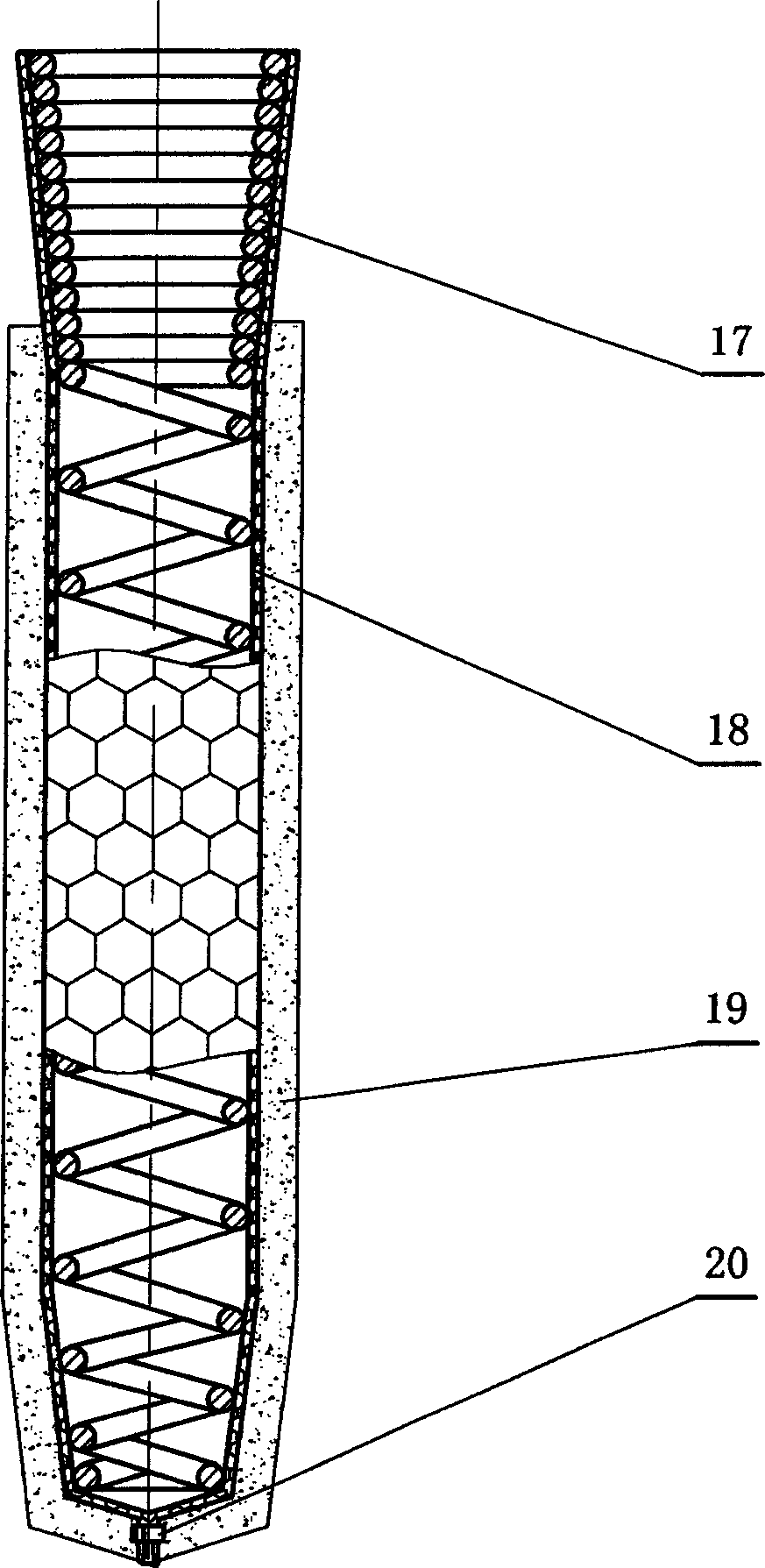

[0046] Such as figure 1 , figure 2 , image 3 ,, Figure 4shown. The raw water enters from the top of the mixing tank 1, the ozone in the ozone generator 5, the solution in the hydrogen peroxide injection tank 4, and the water enter from the bottom of the vortex pump 3 to mix with the raw water and then enter the reaction tank 2 to complete the highly oxidized contact reaction , the filter pump 9 and the filter tank 10 are arranged behind the reaction tank 2 through pipelines in sequence. Residual ozone thermal decomposer 6 is a device for treating the gas generated during ozone oxidation into harmless gas discharge, installed on the upper part of the reaction tank 2; when the filter resistance increases to the set value, stop the filter work, enter the backwashing program, first open the filter The blowdown valve at the lower part of the tank 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com