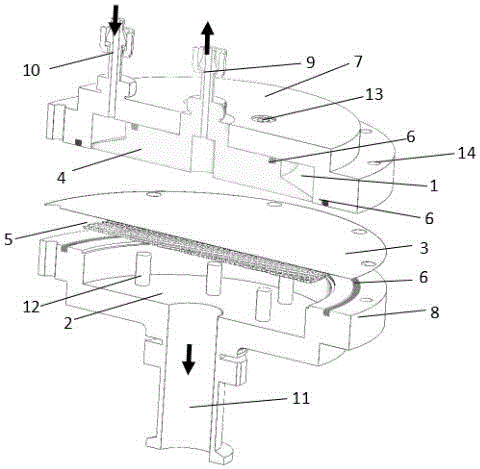

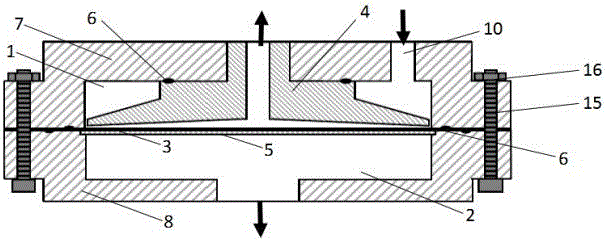

Flat sheet membrane permeability testing assembly

A technology for permeability and testing components, which is applied in the field of membrane separation, can solve problems such as short circuit and concentration polarization, and achieve the effects of improving separation efficiency, improving effective distribution, and being simple and convenient to install and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The raw material liquid / gas enters the feed channel 10 under the action of pressure, reaches the feed cavity 1, passes through the distributor 4 to divide the flow, and passes through the gap between the two ends of the distributor and the periphery of the upper end cover 7 to reach the surface of the diaphragm for distribution. Driven by pressure, the feed liquid / gas that passes through the membrane enters the permeate cavity 2 to collect and enter the permeate channel 11 , and the feed liquid / gas that does not pass through the membrane enters the retentate channel 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com