Microwave refrigerated dough for making crisp pancake and its making method

A technology of microwave freezing and dough, which is applied in the field of food processing, can solve the problems of large area occupied by production equipment, reduced brittleness, troublesome production, etc., and achieve high food nutrition preservation rate, no carcinogens, and small production equipment area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

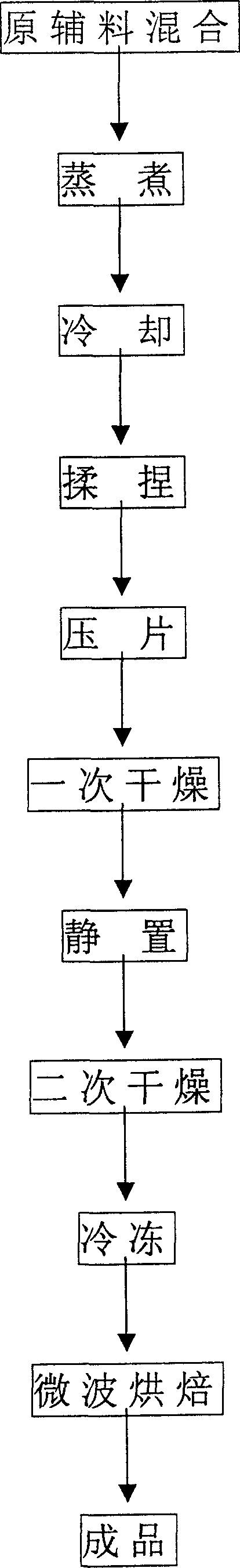

Method used

Image

Examples

Embodiment 1

[0021] Its composition and proportioning are by (weight percentage) in the embodiment of the present invention:

[0022] In the embodiment of the present invention, first mix and cook: take japonica rice flour: 41.0, potato starch: 3.0, almond flour: 10.0, glutinous rice flour: 10.0, salt: 1.5, chicken essence: 1.5 and mix evenly into the cooking pot Internal cooking, add a certain amount of water: 41.0 airtight, heating temperature: 105 ° C, heating time: 10min, the water content of the cooked rice ball should reach 40% by weight;

[0023] Cooling and kneading: Take the hot rice balls out of the cooking pot, cool them with running water, the water temperature is preferably 35°C, and knead them by hand until the rice balls have a uniform texture, so that the rice balls have good elasticity and a smooth surface;

[0024] Tablet forming, one-time drying: the kneaded rice ball is rolled into a 2mm thick cake dough on a roll forming machine. Dry at 70°C for 1.5h until the moistur...

Embodiment 2

[0027] Embodiment two: its composition and proportioning are by (weight percentage) in the embodiment of the present invention:)

[0028] In the embodiment of the present invention, first mix and cook: take japonica rice flour: 42.5, potato starch: 2.5, almond flour: 8.5, glutinous rice flour: 8.5, salt: 1.1, chicken essence: 1.1 and mix evenly into the cooking pot Internal cooking, adding a certain amount of water: 36.5 airtight, heating temperature: 113 ° C, heating time: 13 minutes, the water content of the cooked rice ball should reach 43% by weight;

[0029] Cooling and kneading: Take the hot rice balls out of the cooking pot, cool them with running water, the water temperature is preferably 38°C, and knead them by hand until the rice balls have a uniform texture, so that the rice balls have good elasticity and a smooth surface;

[0030] Tablet molding, one-time drying: the uniformly kneaded rice dough is rolled into a 2.3mm thick cake dough on a roll forming machine, dri...

Embodiment 3

[0033] Embodiment three: its composition and proportioning are by (weight percentage) in the embodiment of the present invention:

[0034] In the embodiment of the present invention, first mix and cook: take japonica rice flour: 44.0, potato starch: 2.0, almond flour: 7.0, glutinous rice flour: 7.0, salt: 0.7, chicken essence: 0.7 and mix evenly into the cooking pot Internal cooking, adding a certain amount of water: 32.0 airtight, heating temperature: 120, heating time: 15min, the water content of the cooked rice ball should reach 45% by weight;

[0035] Cooling and kneading: Take the hot rice balls out of the cooking pot, cool them with running water, the water temperature is preferably 40°C, and knead them by hand until the rice balls have a uniform texture, so that the rice balls have good elasticity and a smooth surface.

[0036] Tablet forming, one-time drying: the uniformly kneaded rice dough is rolled into a 2.5mm thick cake dough on a roll forming machine, dried at 72...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com