Method for removing free formaldehyde in amino resin modified by hydroxylic acrylic ester

A technology of hydroxyacrylic acid and amino resin is applied in the field of removal of free formaldehyde in hydroxy acrylate modified amino resin, which can solve the problem that amino resin cannot be modified with hydroxy acrylate, and achieve the effect of expanding the application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

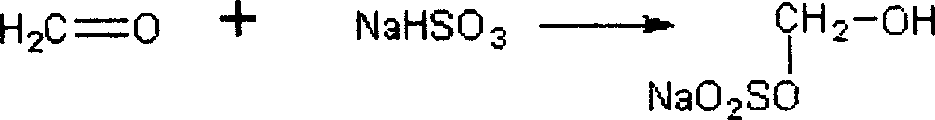

[0012] In a 1000ml four-necked glass bottle with a stirring and reflux water separation device, put 400g of hydroxyethyl acrylate etherified urea-formaldehyde resin containing 1.5% of free formaldehyde, stir and raise the temperature to 65°C, adjust the pH to 7 with 30% NaOH aqueous solution, Add 30g NaHSO dropwise in 30 minutes 3 Saturated aqueous solution; after half an hour of heat preservation reaction, add 400g cyclohexane and 2g p-hydroxyanisole, heat up to 75°C and start reflux dehydration, after 1.5 hours, the temperature of the material rises to 87°C and no water comes out, stop water separation, and cool down to room temperature , precipitated for 0.5 hours, poured out the supernatant, filtered the lower layer with a Buchner funnel, combined the filtrate and the supernatant, put it upside down in a four-necked beaker, reheated, and removed cyclohexane under reduced pressure to obtain etherification of ethyl hydroxyacrylate Urea-formaldehyde resin 390g, yield 97.5%. ...

Embodiment 2

[0014] In a 1000ml four-necked flask with a stirring and reflux water separation device, put 400g of hydroxyethyl acrylate etherified melamine formaldehyde resin containing 0.8% of free formaldehyde, stir and heat up to 65°C, and adjust the pH with 50% NaOH aqueous solution to 7. Add 40g NaHSO dropwise within 30 minutes 3 Saturated aqueous solution, heat preservation reaction for half an hour, add 400g of benzene and 2g of 2,6-di-tert-butyl-p-cresol, heat up to 77°C and start reflux to separate water, after 1.5 hours, the temperature of the material rises to 89°C, no water comes out, stop Separate water, cool down to room temperature, vacuum filter with Buchner funnel, and remove benzene from the filtrate under reduced pressure to obtain 391g of ethyl hydroxyacrylate etherified melamine formaldehyde resin, the yield is 97.8%, and the measured free formaldehyde content is 0.033% .

Embodiment 3

[0016] In a 1000L stainless steel reactor (with condenser, overhead tank, and water separator), throw 500Kg of hydroxyethyl acrylate etherified urea-formaldehyde resin containing 1.5% of free formaldehyde, start stirring, turn on the jacket steam switch, and heat up to 65°C ±2°C, then add 0.5Kg 50% NaOH aqueous solution to adjust the pH to 7.1. Then prepare NaHSO 3 50Kg of the saturated solution is pumped into the high-level tank, and added dropwise to the reactor, and the dropwise addition is completed within 35 minutes. Keep warm at 65°C±2°C for 45 minutes, then add 500Kg toluene and 2.5Kg p-hydroxyanisole, raise the temperature to 102°C and start to reflux and divide water. After 1.5 hours, the temperature of the material will rise to 112°C. No water will come out from the water separator, and the temperature will be lowered. to room temperature. The feed liquid is filtered through a CF pressure filter; the filtrate is colorless and transparent. The filtrate was pumped i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com