Filled skutterudite-based alloy, production method thereof and thermoelectric conversion device fabricated using the alloy

A technology of skutterudite and base alloy, which is applied in thermoelectric devices that only utilize the Peltier or Seebeck effect, junction lead-out materials of thermoelectric devices, and manufacturing/processing of thermoelectric devices. Mineral thermoelectric conversion components and other issues, to achieve satisfactory mechanical strength, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

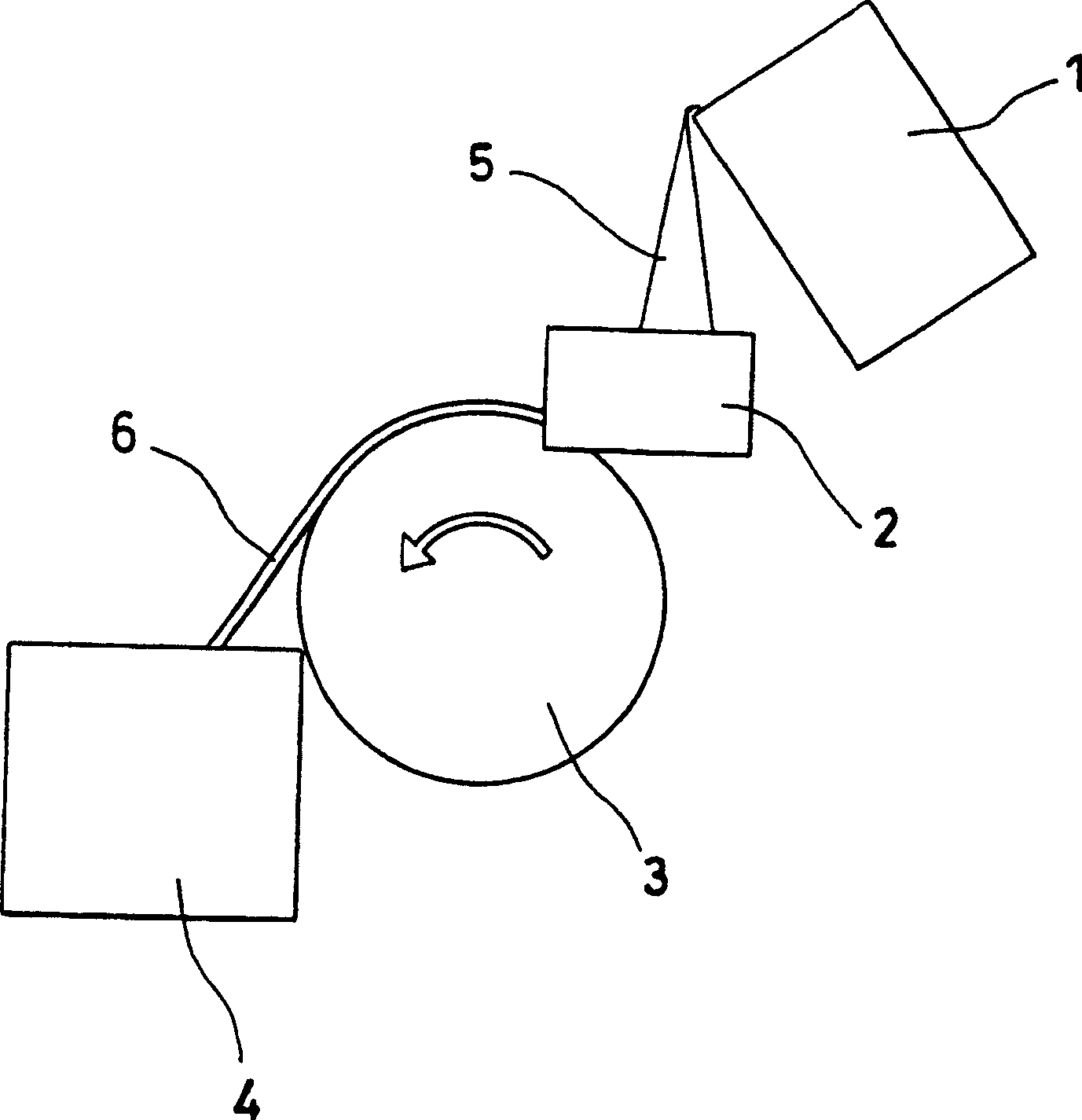

[0046] Weigh the rare earth metal La, electrolytic iron and Sb to obtain LaFe 4 Sb 12 stoichiometric composition. The mixture was melted in an Ar gas atmosphere of 0.1 MPa by heating the mixture to 1400°C. Subsequently, through figure 1 The strip casting apparatus shown pours the molten alloy onto copper rolls cooled with water and rotates at a rotational speed of 0.92m / s, with a pouring speed of 150g / s and a pouring width of 85mm such that Alloy bars were formed with a thickness of 0.28 mm. Estimated cooling rate during casting is about 1×10 3 °C / sec.

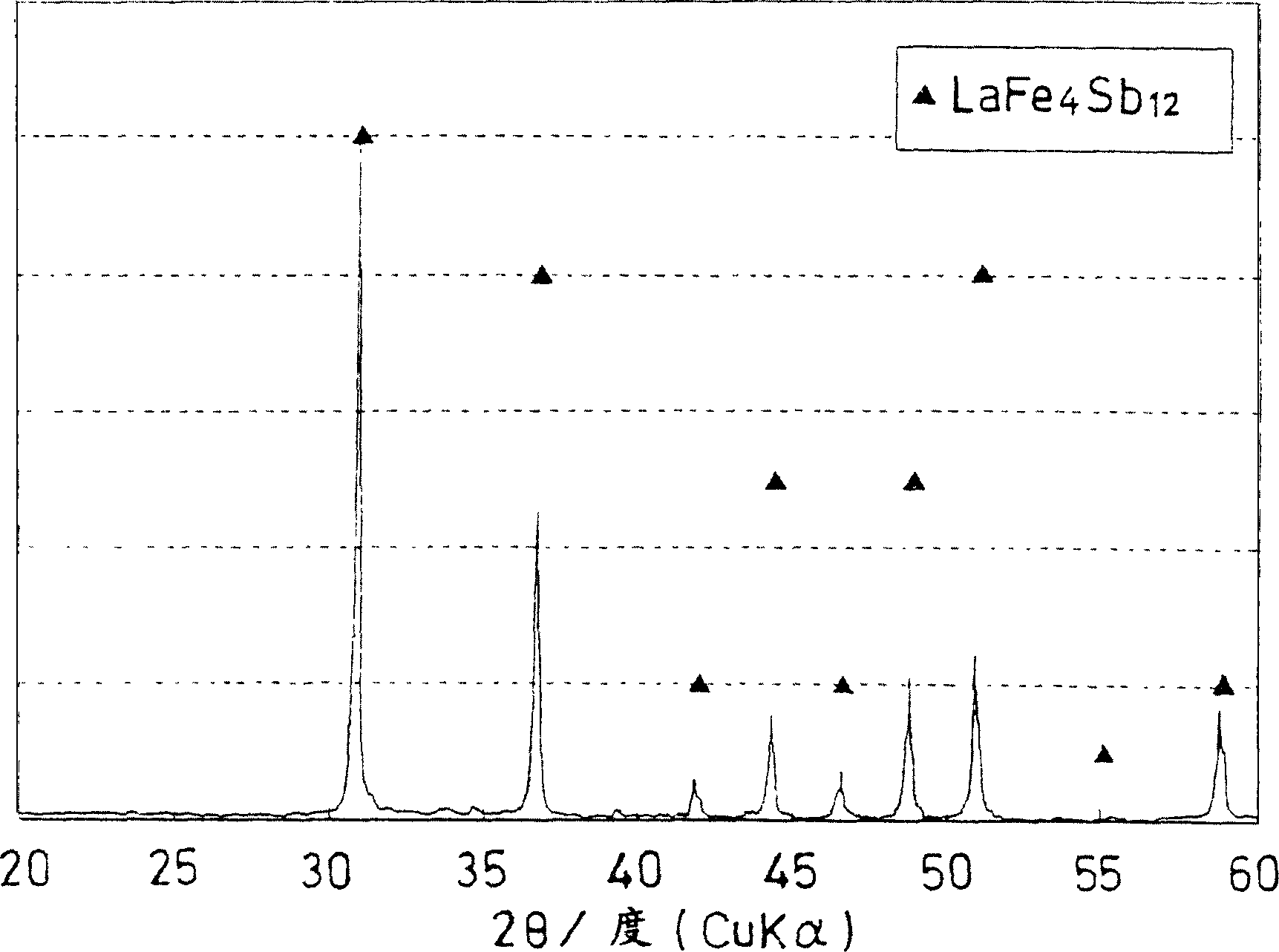

[0047] The alloy bars thus formed were ground and the powder formed was analyzed by powder X-ray diffraction measurements. Such as figure 2 As shown, almost no Sb was observed 2 Fe or Sb peaks. According to the calculation of the figure, it is found that the filled skutterudite phase (such as LaFe 4 Sb 12 ) content is 98% or higher, and Sb 2 The content of Fe is 2% or less.

[0048] The alloy strip thus formed wa...

example 2

[0050] A misch metal, electrolytic iron and Sb (99%) comprising 53% by mass of the rare earth metal Ce and 47% by mass of the rare earth metal La was weighed to obtain (Ce x , La 1-x )Fe 4 Sb 12 stoichiometric composition. The mixture was melted in an Ar gas atmosphere of 0.1 MPa by heating the mixture to 1400°C. Subsequently, through figure 1 The strip casting apparatus shown pours the molten alloy onto copper rolls cooled with water and rotates at a rotational speed of 0.92m / s, with a pouring speed of 150g / s and a pouring width of 85mm such that Alloy bars were formed with a thickness of 0.28 mm.

[0051] The alloy bars thus formed were ground and the powder formed was analyzed by powder X-ray diffraction measurements. The results show that the filled skutterudite (eg (Ce x , La 1-x )Fe 4 Sb 12 ) phase content is 98% or higher, while Sb 2 The content of Fe is 2% or less.

[0052] Immediately after finishing casting the alloy, the cooling rate in the receiving box...

example 3

[0054] Weigh the rare earth metal La, electrolytic iron and Sb to obtain LaFe 4 Sb 12 stoichiometric composition. The mixture was melted in an Ar gas atmosphere of 0.2 MPa by heating the mixture to 1400°C. Subsequently, through figure 1 The strip casting apparatus shown pours the molten alloy onto copper rolls cooled with water and rotates at a rotational speed of 0.92m / s, with a pouring speed of 150g / s and a pouring width of 85mm such that Alloy bars were formed with a thickness of 0.28 mm.

[0055] The alloy bars thus formed were ground and the powder formed was analyzed by powder X-ray diffraction measurements. The results show that the filled skutterudite (such as LaFe 4 Sb 12 ) phase content is 95% or higher, while Sb 2 The content of Fe is 5% or less.

[0056] The alloy strip thus formed was then subjected to heat treatment at 550° C. for one hour in an Ar flow at atmospheric pressure. Powder X-ray diffraction measurements showed that the heat-treated product co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com