Sulfur based corrosion inhibitors

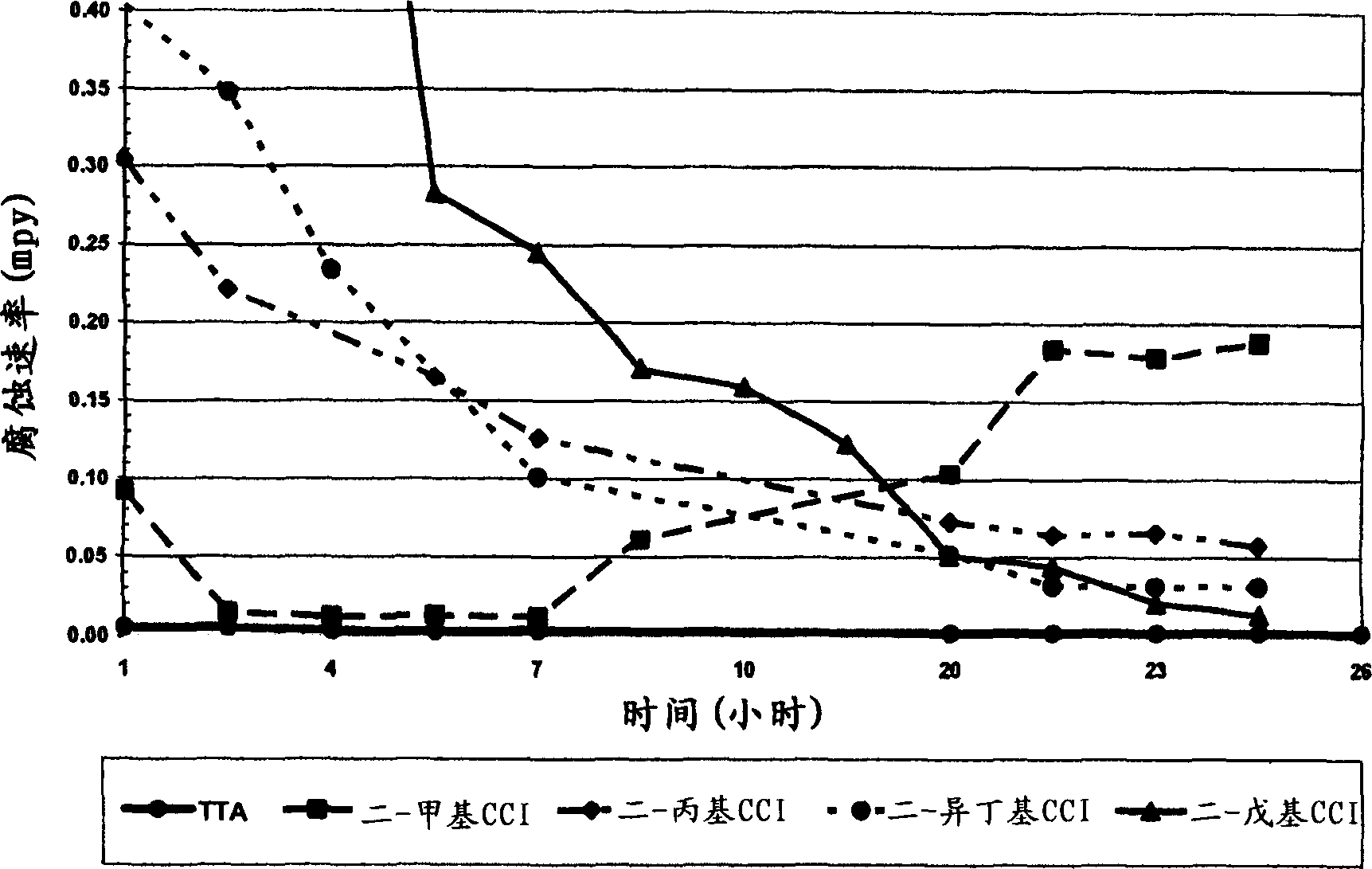

By forming a durable protective barrier, sulfur-based corrosion inhibitors solve the problem of triazole corrosion inhibitors being sensitive to chlorine degradation and requiring residual inhibitors, achieving anti-corrosion effects without residue, reducing costs and monitoring frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126] Preparation of sodium dimethyldithiocarbamate in aqueous solution

[0127] A clean and dry four-necked 500 mL flask was charged with 59.6 g of tap water, 39.0 g (0.52 mol) of 60% dimethylamine in water, and a large stir bar. Stirring was started and the flask was fitted with a condenser, thermocouple and heating mantle. A 25 mL addition funnel was charged with 38.0 g (0.50 mol) of carbon disulfide and the addition funnel was loaded onto the reaction flask. A 50 mL addition funnel was charged with 40.0 g (0.50 mol) of 50% sodium hydroxide, which was then loaded onto the reaction flask. The reaction was then heated to 30°C with stirring.

[0128] When the contents of the reactor reached 30°C, the addition of carbon disulfide was started at a slow drop rate. After 5 minutes, sodium hydroxide was also added at a slow dropwise rate. The additions were adjusted so that the reaction temperature did not exceed 45°C, and after about 1 hour both additions were complete. The ...

Embodiment 2

[0130] Preparation of sodium diethyldithiocarbamate in aqueous solution

[0131] A clean dry four-neck 500 mL flask was charged with 113 g of tap water, 19.0 g (0.26 mol) of diethylamine, and a large stir bar. Stirring was started and the flask was fitted with a condenser, thermocouple and heating mantle. A 25 mL addition funnel was charged with 19.0 g (0.25 mol) of carbon disulfide, which was then loaded onto the reaction flask. A 50 mL addition funnel was charged with 20.0 g (0.50 mol) of 50% sodium hydroxide and the addition funnel was loaded onto the reaction flask. The reaction was then heated to 30°C with stirring.

[0132] When the contents of the reactor reached 30°C, the addition of carbon disulfide was started at a slow drop rate. After 5 minutes, sodium hydroxide was also added at a slow dropwise rate. The additions were adjusted so that the reaction temperature did not exceed 45°C, and after about 1 hour both additions were complete. The reaction was then boil...

Embodiment 3

[0134] Preparation of sodium dipropyldithiocarbamate in aqueous solution

[0135]A clean dry four-necked 500 mL flask was charged with 189 g of tap water, 36.9 g (0.365 mol) of dipropylamine (Aldrich, 99%), and a large stir bar. Stirring was started and the flask was fitted with a condenser, thermocouple and heating mantle. A 25 mL addition funnel was charged with 26.6 g (0.35 mol) of carbon disulfide, which was then loaded onto the reaction flask. A 50 mL addition funnel was charged with 28.0 g (0.35 mol) of 50% sodium hydroxide and the addition funnel was loaded onto the reaction flask. The reaction was then heated to 30 °C with stirring.

[0136] When the contents of the reactor reached 30°C, the addition of carbon disulfide was started at a slow drop rate. After 5 minutes, sodium hydroxide was also added at a slow dropwise rate. The additions were adjusted so that the reaction temperature did not exceed 45°C, and after about 1 hour both additions were complete. The re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| composition ratio | aaaaa | aaaaa |

| composition ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com