Separator and non-aqueous electrolyte battery using the separator

A non-aqueous electrolyte and separator technology, applied in non-aqueous electrolyte batteries, secondary batteries, battery electrodes, etc., to achieve the effect of thinning and ensuring battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

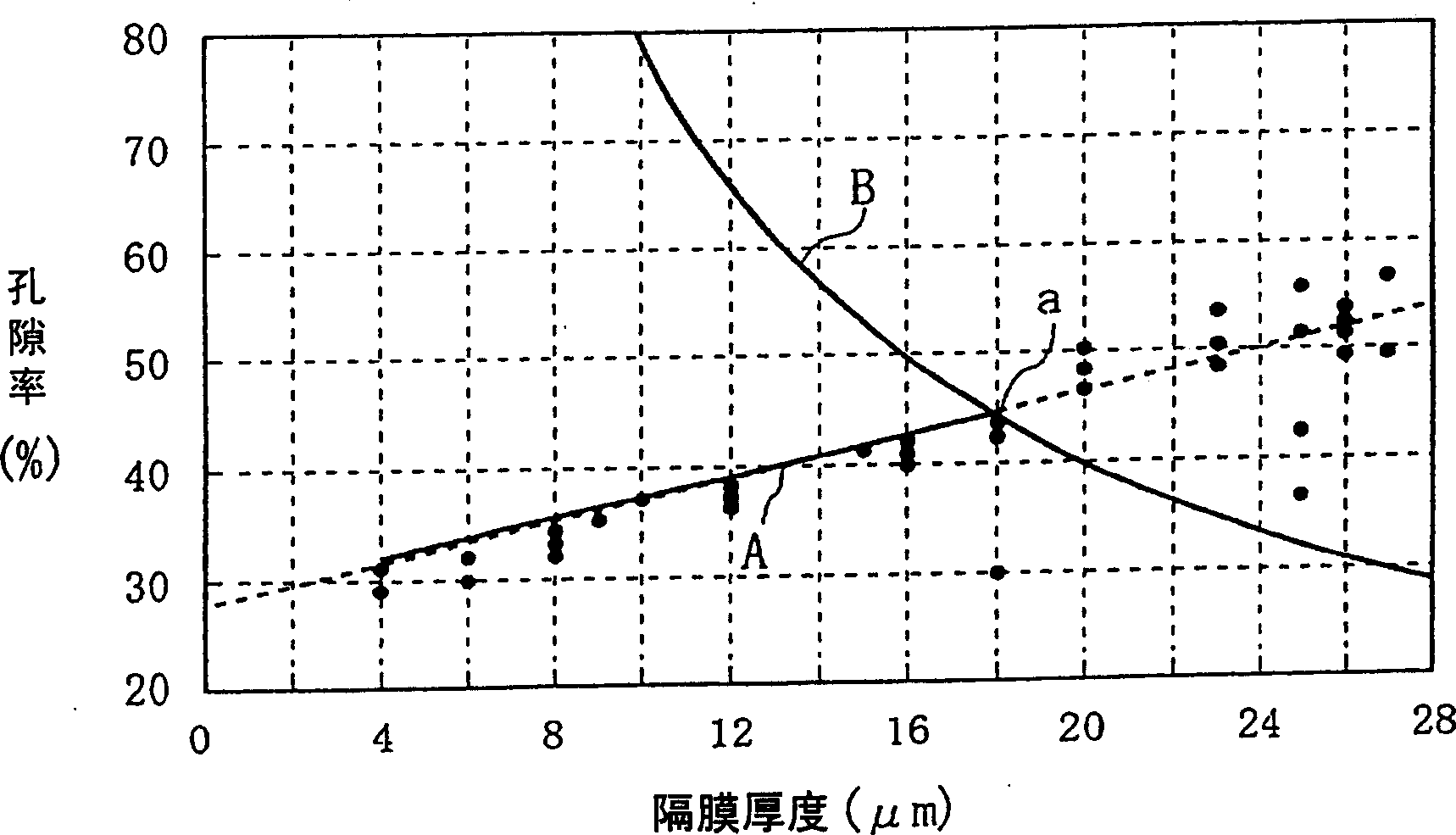

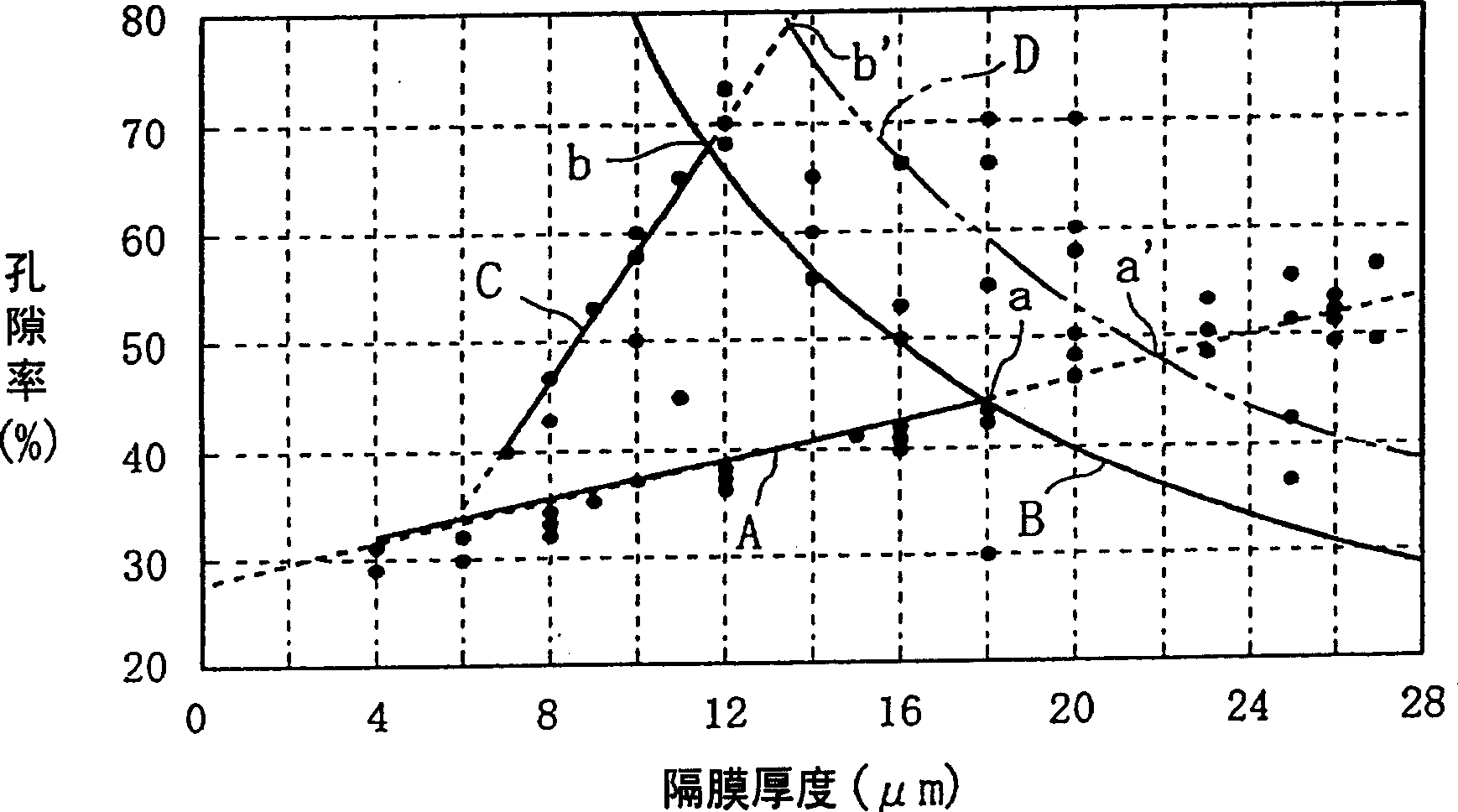

[0118] The thickness of the polyethylene (PE) film as the reinforcement film is 4 μm, and the thickness of the para-oriented aromatic polyamide (PA) film as the heat-resistant film is changed. Batteries were made in the same way. Among them, the thickness of the polyethylene film used as the reinforced film is set to 4 μm. This is because even if the reinforced film is used, it is necessary to study whether it can be supplemented with a heat-resistant film. In addition, in order to ensure the maximum liquid retention, the heat-resistant film The porosity was adjusted so as to be 80% of the maximum value during optimization by the inventors of the present invention.

[0119] The batteries thus produced are hereinafter referred to as batteries A1 to A5 of the present invention, respectively.

Embodiment 1~10

[0132] Same as the best embodiment except that the liquid retention is changed by changing the thickness and porosity of the separator, while changing the thickness of the polyethylene (PE) membrane and the thickness of the polyamide (PA) membrane to make batteries.

[0133] The batteries thus produced are hereinafter referred to as batteries B1 to B10 of the present invention, respectively.

[0134] Here, the porosity of the polyamide film is made close to 80% as the limit value, while on the other hand, considering the mechanical strength (stretchability), the porosity of the polyethylene film is adjusted to be close to the limit value. 60% status. The specific reason for thus limiting the porosity of the polyethylene film to 60% is as follows.

[0135] That is, since tension is applied to the separator when winding up the power generating element, a certain degree of tensile strength is required. In this case, when the porosity is high, it is easy to break, which causes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com