Pr series rare earth super magnetostric tive material and its preparing method

A giant magnetostrictive and rare earth technology, which is applied in the field of composition and manufacture of praseodymium rare earth giant magnetostrictive materials, can solve the problem of Laves single-phase compounds that cannot be synthesized with large magnetostriction, and rare earth giant magnets that are difficult to synthesize high Pr content. There is no way to achieve the problem of anisotropy compensation composition points, etc., to achieve the effects of low magnetocrystalline anisotropy, lower price and cost, and large eddy current loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

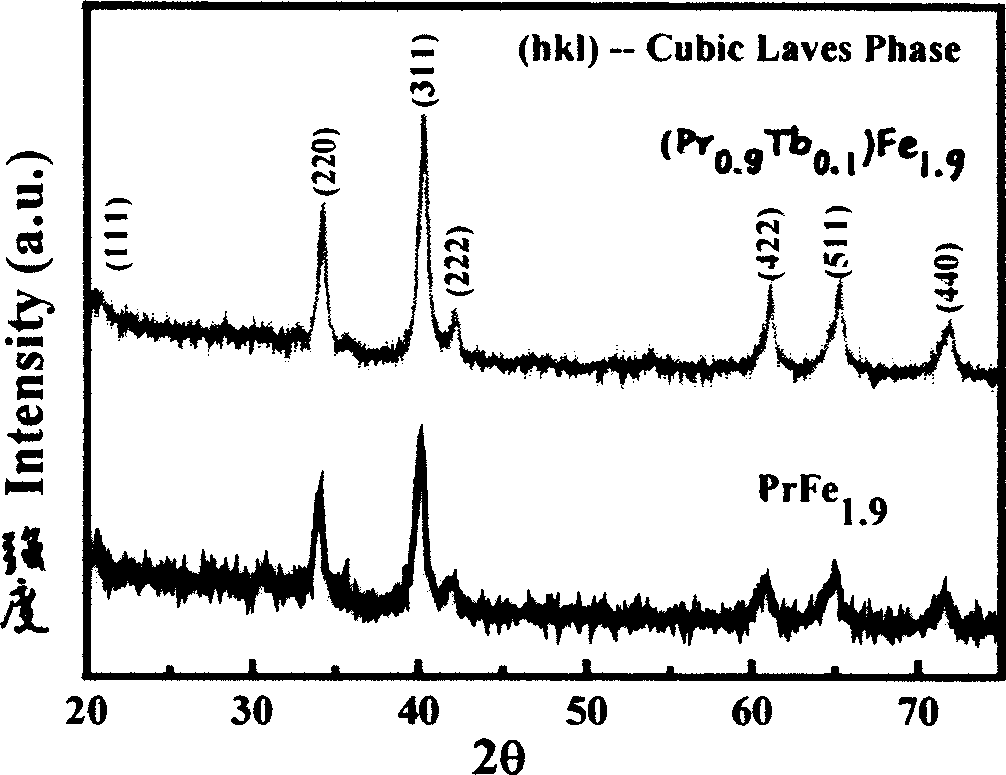

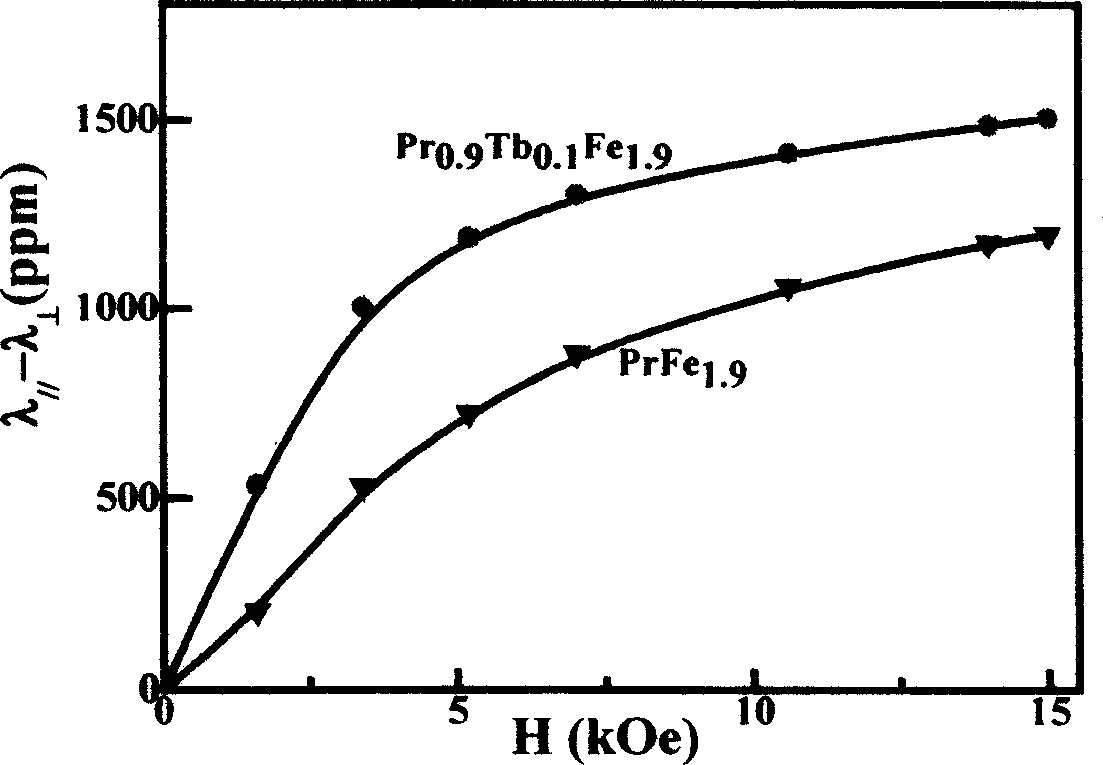

[0031] Composition is Pr 0.9 Tb 0.1 Fe 1.9 alloy. Raw materials with a purity of 99% Tb, 99% Pr, and 99.5% Fe are measured according to the formula Pr 0.9 Tb 0.1 Fe 1.9 (atomic ratio) ratio. The proportioned raw materials are put into the crucible of the arc melting furnace, and the alloy ingot with uniform composition is obtained by arc melting. The brittle alloy ingot is broken into powders with a diameter of 2 to 5 mm, put into a mold with a diameter of 10 mm and a length of 20 mm, and preformed with a pressure of 50 MPa. Then wrap it with Ta skin, put it into a pyrophyllite mold with a diameter of 11mm, keep it warm at a pressure of 6GPa and a temperature of 900°C for 30 minutes, and then cool it to room temperature under pressure. Finally, a rod of praseodymium rare earth magnetostrictive material is obtained. The x-ray diffraction pattern and magnetostrictive properties of this material are shown in figure 1 and figure 2 .

[0032] Experiments of the present ...

Embodiment 2

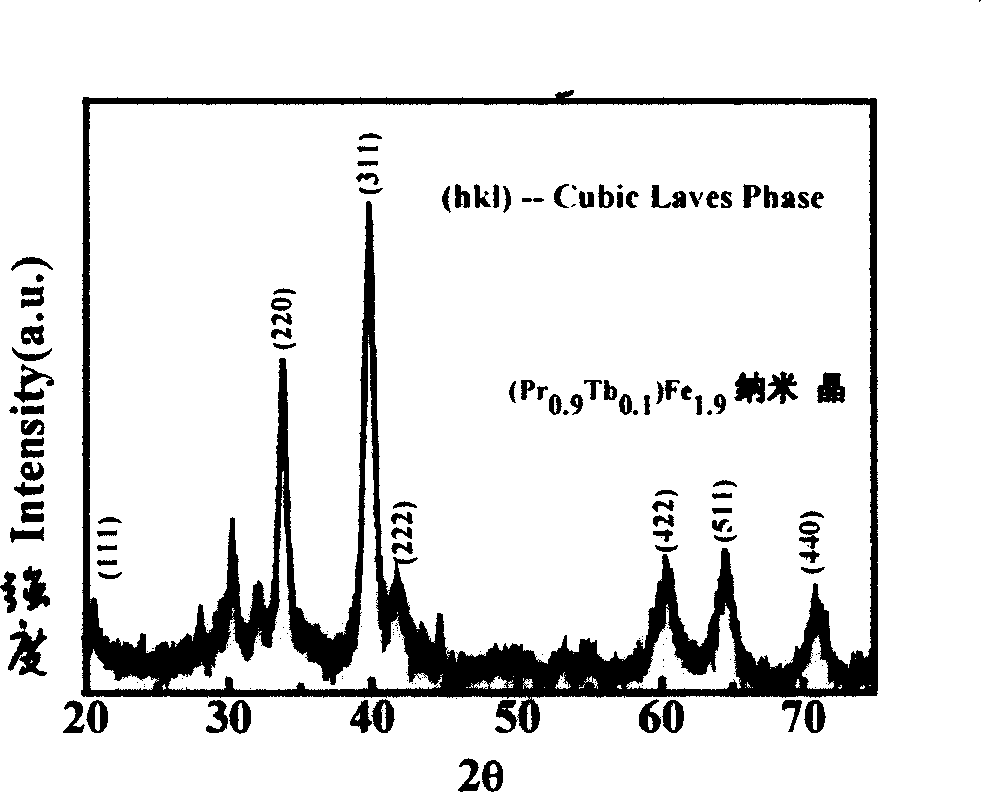

[0035] Composition is Pr 0.9 Tb 0. Fe 1.9 alloy. Raw materials with a purity of 99% Tb, 99% Pr, and 99.5% Fe are measured according to the formula Pr 0.9 Tb 0. Fe 1.9 (atomic ratio) ratio. The proportioned raw materials are put into the crucible of the arc melting furnace, and the alloy ingot with uniform composition is obtained by arc melting. Put the alloy into the melt rapid quenching equipment, use medium frequency induction heating to melt the alloy to form an alloy solution, and make the alloy solution pass through the water-cooled copper wheel with a rotation speed of 30m / s, and throw it into strips where nanocrystalline and amorphous coexist . Break the strips into powders with a size of 2-5 mm, put them into a mold with a diameter of 10 mm and a length of 20 mm, and preform with a pressure of 50 MPa. Then wrap it with Ta skin, put it into a pyrophyllite mold with a diameter of 11mm, keep it warm at a pressure of 6GPa and a temperature of 600°C for 30 minutes, ...

Embodiment 3

[0037] Composition is PrFe 1.9 alloy. Raw materials with a purity of 99% Pr and 99.5% Fe are measured according to the formula PrFe 1.9 (atomic ratio) ratio. The proportioned raw materials are put into the crucible of the arc melting furnace, and the alloy ingot with uniform composition is obtained by arc melting. The brittle alloy ingot is broken into powders with a diameter of 2 to 5 mm, put into a mold with a diameter of 10 mm and a length of 20 mm, and preformed with a pressure of 50 MPa. Then wrap it with Ta skin, put it into a pyrophyllite mold with a diameter of 11mm, keep it warm for 30 minutes at a pressure of 6GPa and a temperature of 700-900°C, and then cool it to room temperature under pressure. Finally, a rod of praseodymium rare earth magnetostrictive material is obtained. The x-ray diffraction pattern and magnetostrictive properties of this material are shown in figure 1 and figure 2 .

[0038] When the pressure is 50 MPa and the temperature is 300-900° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com