Device and method for preparing nanometer oxide nesa by ultrasound rapid deposition method

A transparent conductive film and nano-oxide technology, applied in the direction of metal material coating process, etc., to achieve uniform physical and chemical properties, reduce internal short circuits, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

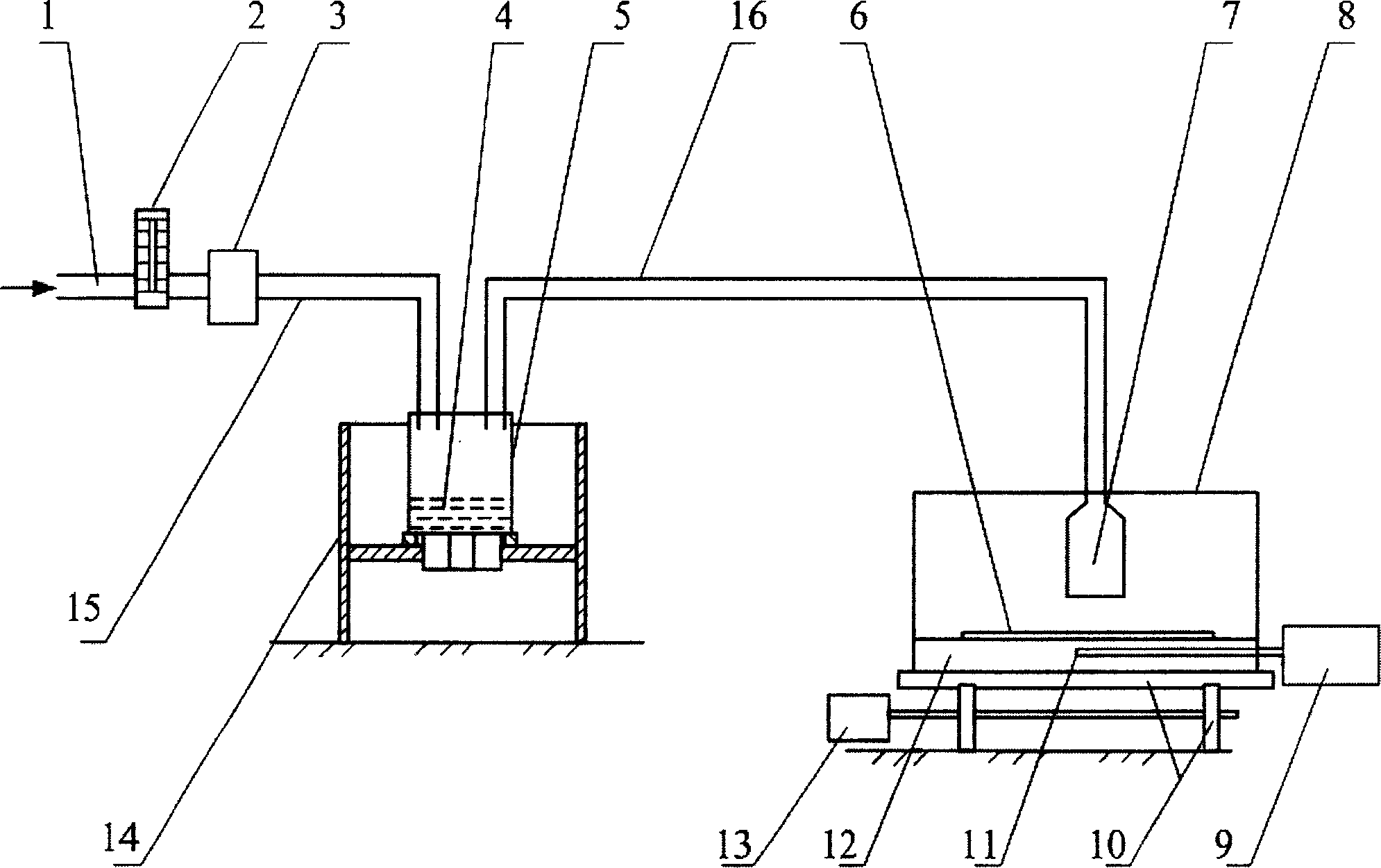

[0030] Preparation of transparent conductive films used in amorphous silicon thin film solar cells, devices such as figure 1 Shown, but to add oxygen cylinders and other carrier gas equipment.

[0031] 1. Preparation process of TCO membrane

[0032] 1.1 Cleaning of substrate material

[0033] The surface of the substrate is first cleaned with deionized water, and then the substrate is soaked in sulfuric acid solution for 2 hours, and then cleaned in an ultrasonic cleaner with an ultrasonic frequency of 20kHz-40Mz for 30 minutes. Take it out and dry it in a clean oven for later use.

[0034] 1.2 Preparation of transparent conductive film

[0035]Firstly, take a certain amount of SnCl4.5H2O, make a solvent with H2O and CH3OH, and then add a certain amount of NH4F aqueous solution in proportion. Put the ultrasonically cleaned 20×20cm glass substrate (6) on the heating furnace (12) and set the temperature of the substrate by the temperature controller (9) to keep the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com