Continuous production method for foamed metal casting and rolling

A foam metal, production method technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., to achieve the effect of continuous production, low cost, and good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

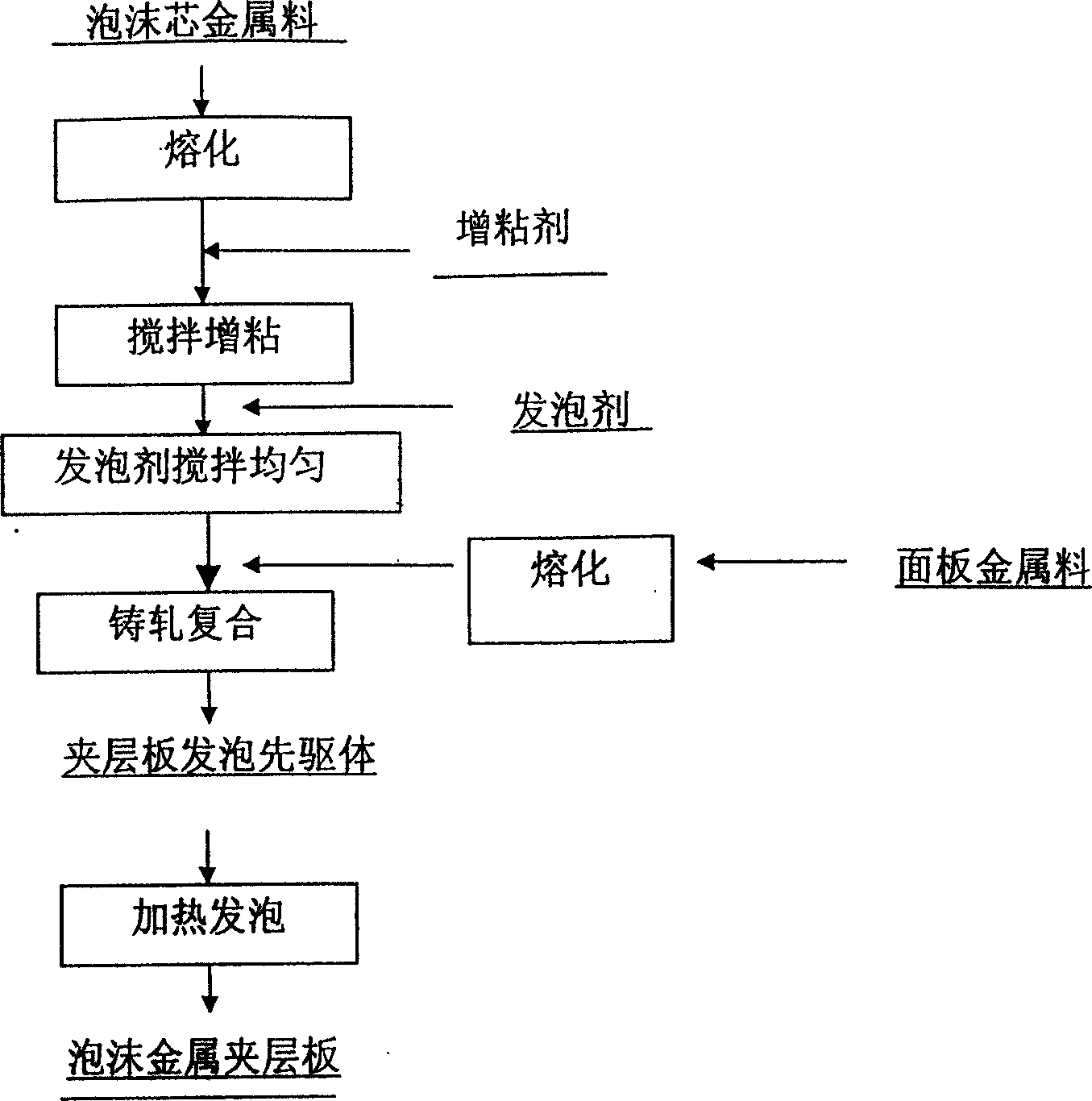

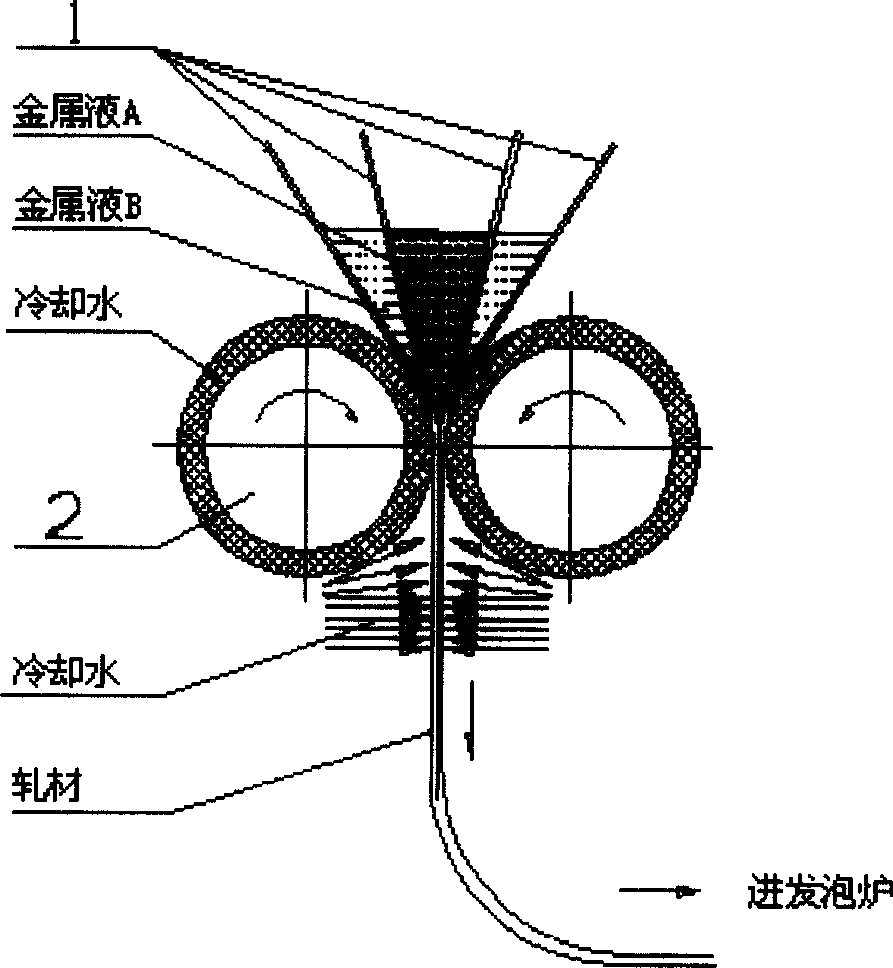

[0039] Example 1: Aluminum-foam aluminum-aluminum sandwich panel

[0040] The panel is made of pure aluminum, and the foam metal core is made of AlSi6 aluminum alloy, which are melted at 720°C and 650°C respectively, and metal calcium is added to the AlSi6 aluminum alloy melt (the dosage is 2% of the mass of AlSi6 aluminum alloy, and the particle size is 1-1.5 mm), stir and thicken with a stirrer (rotating speed 500 rpm, time 15 minutes), then add 200 mesh titanium hydride (consumption is 1.2% of AlSi6 aluminum alloy quality), carry out foaming agent uniform mixing and stirring with a stirrer (speed 1000 rpm, time 120 seconds). Pure aluminum and AlSi6 aluminum alloy mixed uniformly with thickening and foaming agent are poured into a vertical two-roll rolling mill with 4 gears (roll diameter 300 mm, roll body length 800 mm, roll gap 10 mm), using 3 tons of rolling force Rolling at a speed of 1 m / min, the rolling and post-rolling cooling strengths are 20°C / s and 50°C / s respecti...

Embodiment 2

[0041] Example 2: Steel-foam aluminum-steel sandwich panel

[0042] Use 45 steel for the panel and pure aluminum for the core as raw materials, melt at 1450°C and 720°C respectively, add silicon carbide (the amount is 2% of the Al mass, particle size is 200 mesh) into the pure Al melt, and stir with a stirrer Viscosification (rotating speed 600 rpm, time 12 minutes), then add 300 mesh calcium carbonate (consumption is 2% of Al quality), carry out foaming agent uniform mixing and stirring with agitator (rotating speed 1200 rpm, time 100 seconds ). 45 steel, (thickened and evenly mixed with foaming agent) pure aluminum poured into the 4th plate vertical two-roll mill (roll diameter 300 mm, roll body length 800 mm, roll gap 10 mm), using 5 tons of rolling Rolling force and speed of 1.2 m / min, the roller and post-rolling cooling intensity are 30°C / sec and 50°C / sec respectively, and the thickness of 10mm can be continuously obtained (the middle pure aluminum is 8mm, and the two ou...

Embodiment 3

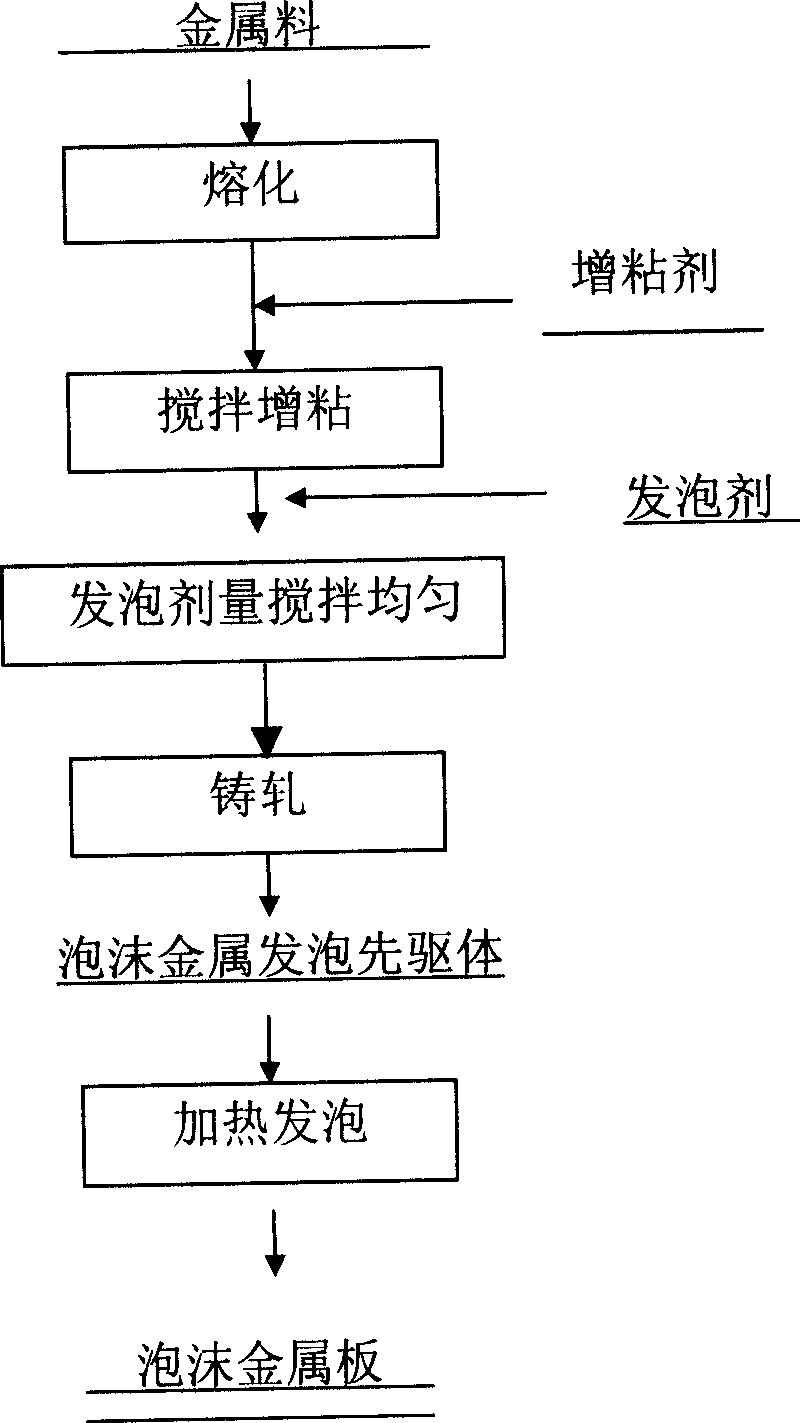

[0043] Embodiment three: aluminum foam

[0044] Use pure aluminum as the raw material, melt it at 720°C, add silicon carbide (the amount is 2% of the mass of Al, particle size 300 mesh) into the pure Al melt, stir and increase viscosity with a stirrer (speed 600 rpm, time 12 minutes), then add 100 mesh titanium hydride (consumption is 1% of Al quality), carry out foaming agent uniform mixing and stirring (rotating speed 1300 rev / mins, time 150 seconds) with agitator, (through viscosifying, foaming agent Evenly mixed) pure aluminum is poured into a vertical two-roll rolling mill with 2 plates (roll diameter 300 mm, roll body length 800 mm, roll gap 10 mm), using 2 tons of rolling force and a rolling speed of 3 m / min. and the cooling intensity after rolling are 15°C / sec and 20°C / sec respectively, a foamed aluminum precursor strip with a thickness of 10mm and a width of 600mm can be obtained, and then the strip is foamed at a temperature of 720°C for 4 minutes to obtain Aluminum f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com