Laminated ceramic capacitor

A technology of ceramic capacitors and laminates, which is applied in the direction of laminated capacitors, fixed capacitor electrodes, multiple fixed capacitors, etc., can solve the problems of poor yield and poor connection of terminal electrodes, etc. The occurrence of cracks is reduced and the yield is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

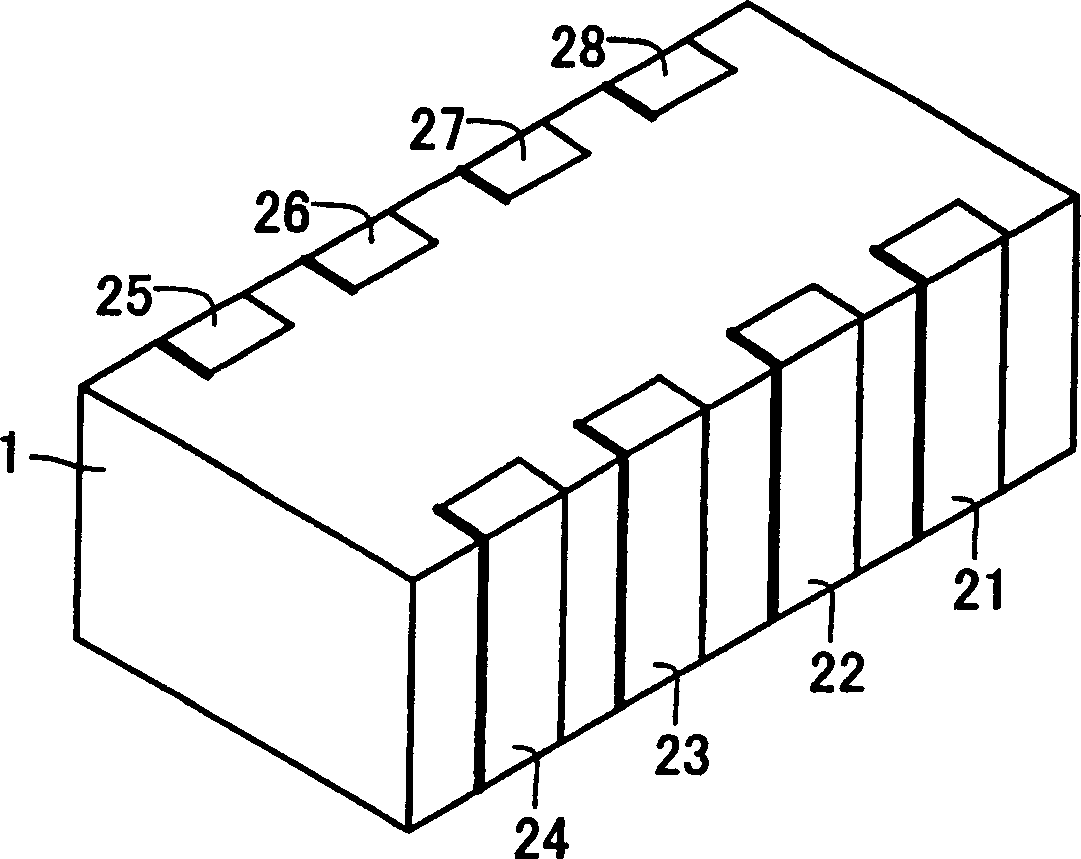

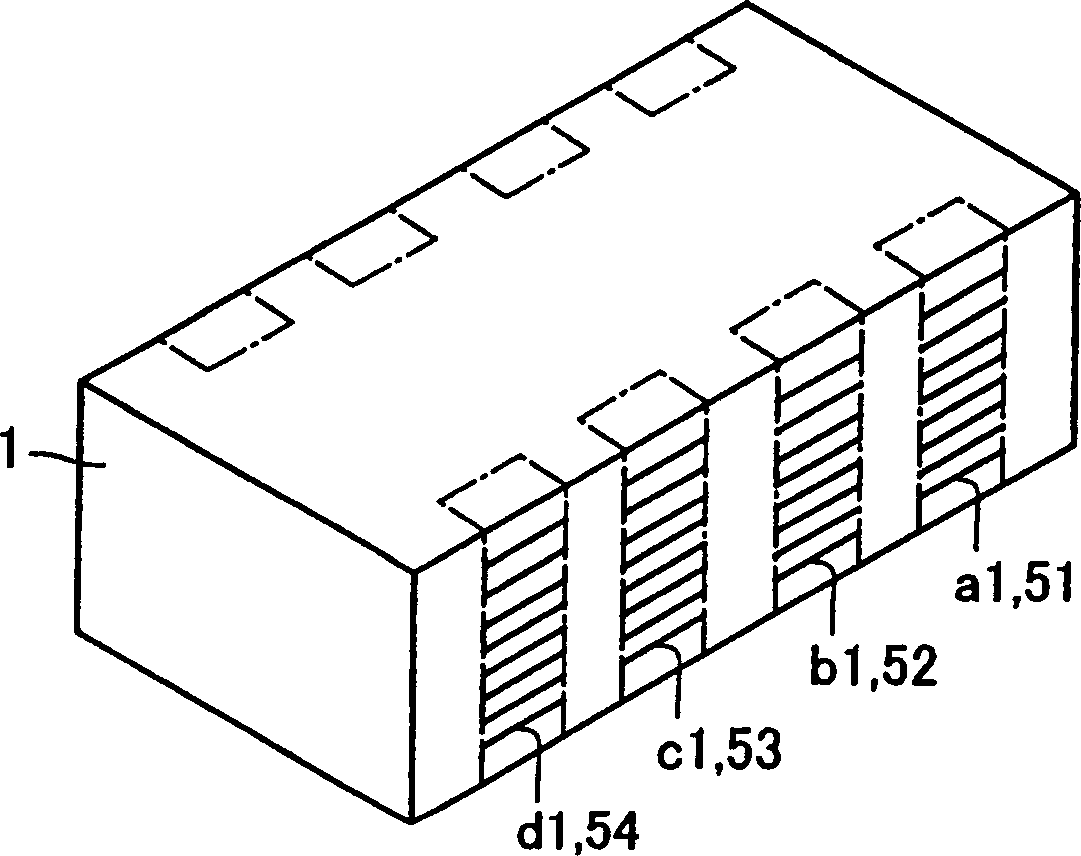

[0060] The laminated ceramic capacitor of Example 1 is Figure 1 to Figure 5 The present invention relates to a laminated ceramic capacitor shown in . The difference between the laminated ceramic capacitor of Comparative Example 1 and Example 1 is that it does not have dummy electrodes. The difference between Comparative Example 2 and the laminated ceramic capacitor of Example 1 is that the dummy electrodes are not exposed on the side surfaces of the ceramic main body.

[0061] incidence of delamination

Incidence of Fragmentation

Incidence of poor connections

Example 1

0.2%

0.2%

0.1%

Comparative example 1

1.0%

1.0%

1.0%

Comparative example 2

0.3%

0.3%

0.5%

[0062] Referring to Table 1, the occurrence rate of delamination, chipping and poor connection of Comparative Example 1 was 1.0%, which was very high. In Comparative Example 2, the occurrence rate of del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com