Polymer film modified electrode and preparation method and application thereof

A polymer film and modified electrode technology, applied in the direction of material electrochemical variables, etc., can solve the problems of short service life, easy poisoning, etc., and achieve high yield, low cost, and good electrode response sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

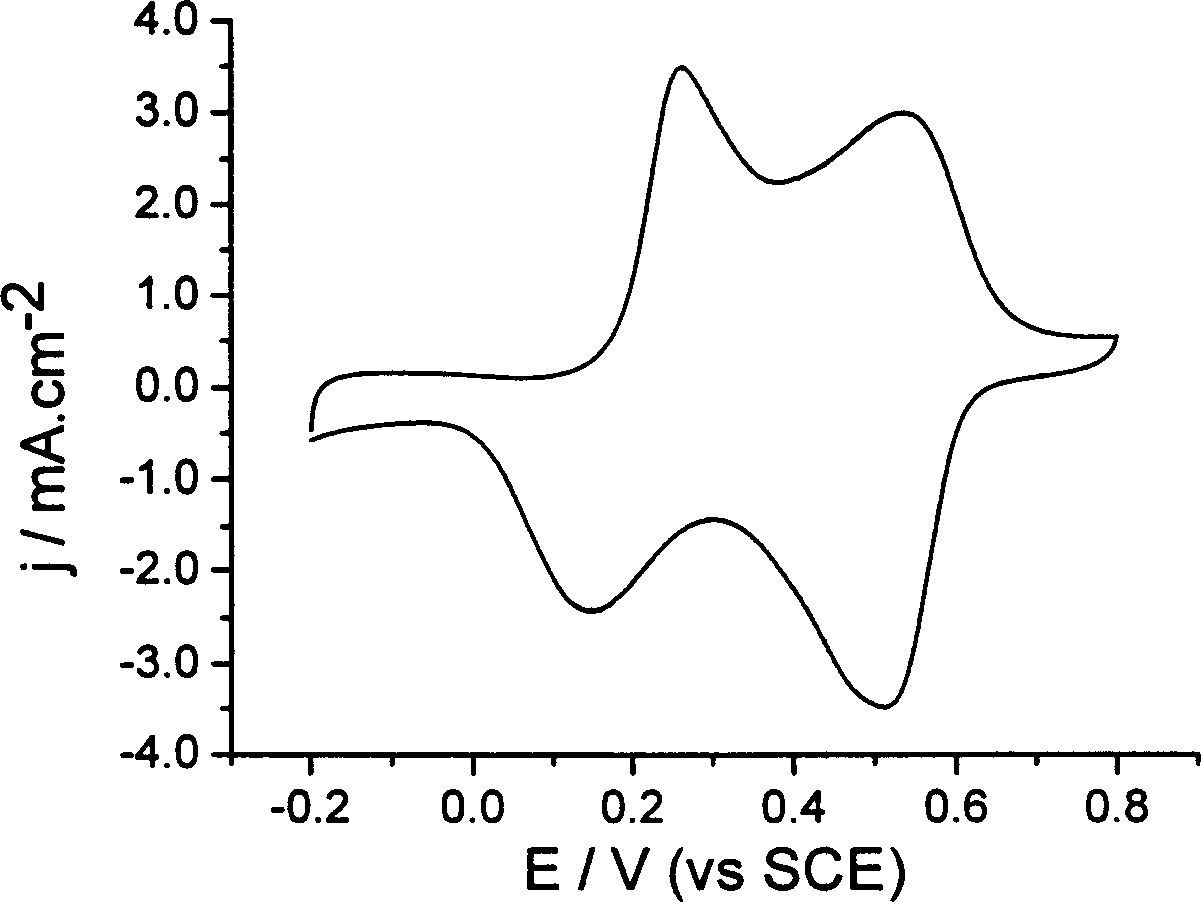

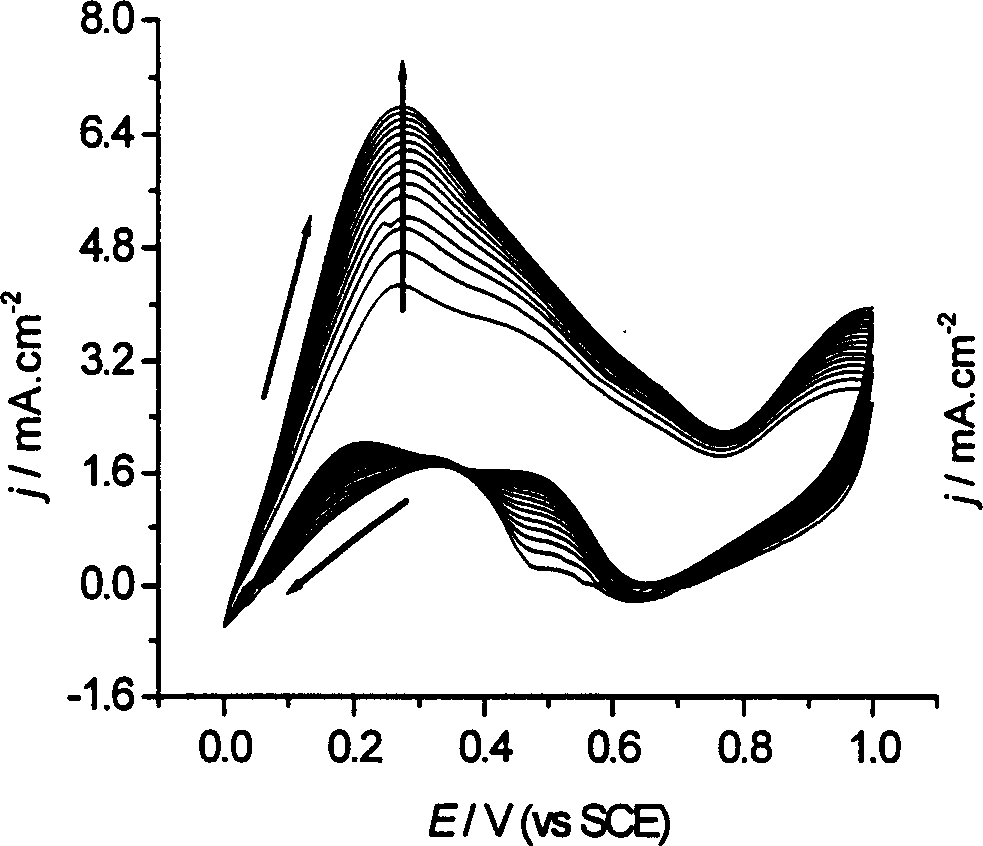

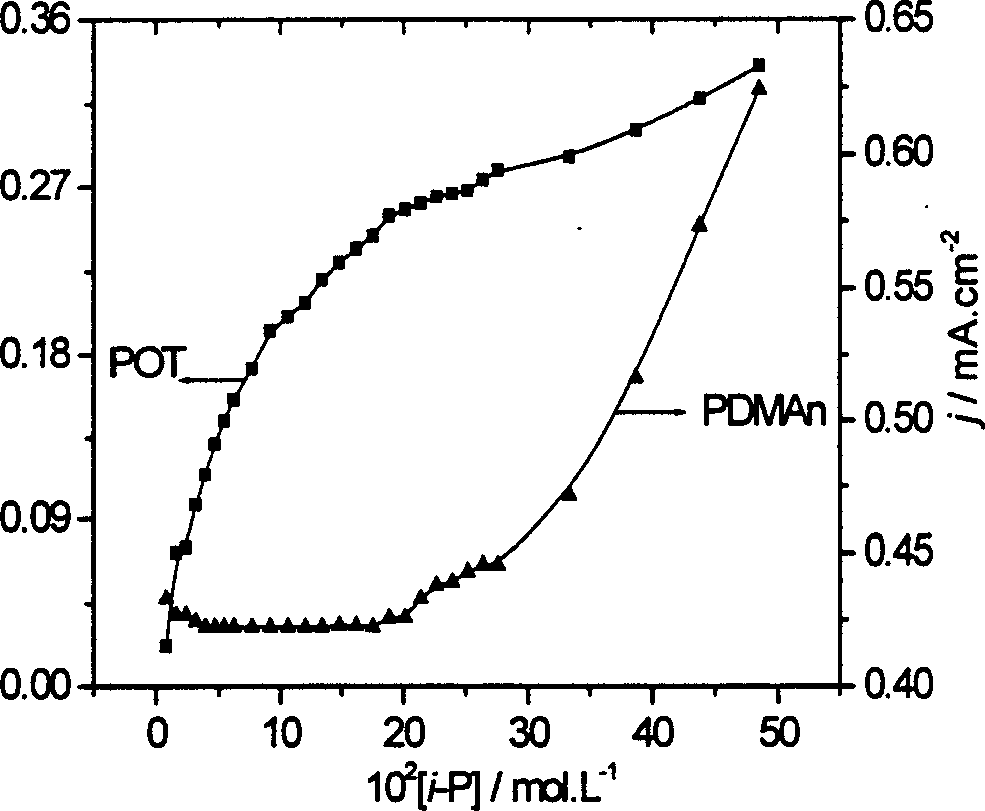

Method used

Image

Examples

Embodiment 1

[0027] Add 100mL of 1.0mol / L HCl aqueous solution into a 250mL three-necked flask, put it in an ice bath, and ventilate nitrogen to exhaust oxygen. After the temperature stabilizes at about 2-3°C, add 2.14g of o-toluidine dropwise, [M]=0.01mol / L, Stir well and add 2 drops of saturated CoSO 4solution as a catalyst. Dissolve ammonium persulfate (APS) in 60mL of 1.0mol / L HCl solution, [APS] / [M]=1, slowly drop into the three-necked bottle, about 2.0h to complete the drop. After continuing the reaction for 10 hours, the reaction solution was placed in a refrigerator at 5°C for 36 hours; then the obtained reaction solution was suction-filtered, and the solid content was washed with deionized water until the filtrate was neutral, and then washed several times with ethanol until the filtrate was colorless; Vacuum-dried at 60°C to obtain HCl-doped POT(HCl). Soak the POT (HCl) in 25% ammonia water for 24-48 hours, continue to stir, filter, wash with deionized water until the filtrate ...

Embodiment 2

[0032] Add 120mL of 1.0mol / L TSA aqueous solution into a 250mL three-necked flask, put it in an ice bath, pass nitrogen gas to exhaust oxygen, wait for the temperature to stabilize at around 2-3°C, add 1.5g o-toluidine dropwise, [M]=0.087mol / L, Stir well and add 3 drops of saturated CoSO 4 solution as a catalyst. Dissolve APS in 40mL of 1.0mol / L TSA solution, [APS] / [M]=1.5, slowly drop into the three-necked bottle, about 1.5h to finish. After continuing the reaction for 6 hours, the reaction solution was placed in a refrigerator at 6°C for 48 hours; then the obtained reaction solution was suction-filtered, and the solid content was washed with deionized water until the filtrate was neutral, and then washed several times with ethanol until the filtrate was colorless; Vacuum drying at room temperature to obtain green doped POT (TSA).

[0033] Prepare POT (TSA) into a 3.0mg / mL DMF solution, and use a micro-vortex mixer to aid dissolution; take a certain amount of polymer soluti...

Embodiment 3

[0036] Add 100mL 1.0mol / L HClO to a 250mL three-necked bottle 4 Aqueous solution, ice bath, blow nitrogen to exhaust oxygen, wait for the temperature to stabilize at around 2-3°C, add dropwise 3.0g of o-toluidine, [M]=0.175mol / L, stir well, add 3 drops of saturated CoSO 4 solution as a catalyst. Dissolve APS in 100mL 1.0mol / L TSA solution, [APS] / [M]=2, slowly drop into the three-necked bottle, about 3.0h to finish. After continuing the reaction for 15 hours, the reaction solution was placed in a refrigerator at 8°C for 24 hours; then the obtained reaction solution was suction-filtered, and the solid content was washed with deionized water until the filtrate was neutral, and then washed several times with ethanol until the filtrate was colorless; Vacuum drying at 40°C to obtain green doped POT (HClO 4 ). POT(HClO 4 ) soaked in 25% ammonia water for 24 to 48 hours, continuously stirred, filtered, washed with deionized water to make the filtrate neutral, and then washed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com