A method for improving the electrooxidation anti-CO performance of formic acid fuel cell

A formic acid fuel cell, electro-oxidation technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low utilization efficiency per unit mass of Pt nanostructure catalysts, easy poisoning, etc., achieve excellent area specific activity and improve stability , to ensure the effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

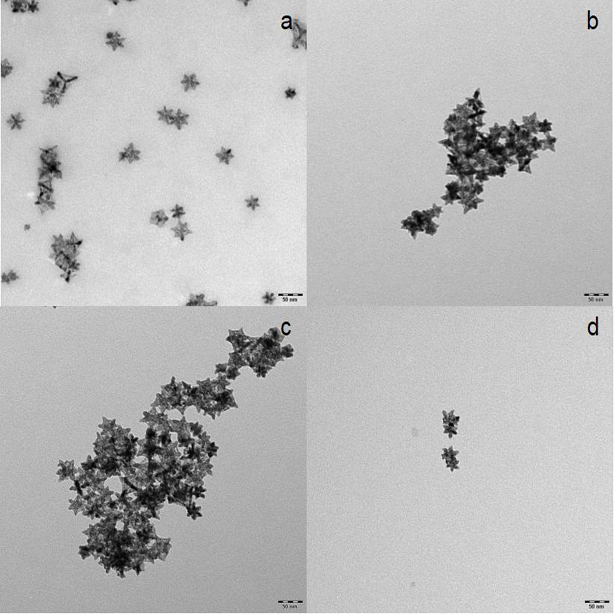

[0025] A Pt-Ni-Cu Ternary Alloy Supporting CeO 2 The experimental steps of the preparation method are as follows:

[0026] (1) Fully ultrasonically disperse the original solution of 1 mL oleylamine corresponding to 3.44 mg CeO2, add (a) 0 mL (b) 0.07 mL (c) 0.2 mL and (d) 0.3 mL respectively to centrifuge tubes, centrifuge, and use Pipette the supernatant until only the precipitate remains. Add 0.7 mL of ethanolamine to ultrasonically disperse to make it evenly dispersed;

[0027] (2) Weigh 303.4 mg of glycine, 200 mg of polyvinylpyrrolidone (PVP), and 300 mg of sodium iodide into a clean beaker;

[0028] (3) Add 2 mL of 20 mM H 2 PtCl 6 aqueous solution, 1 mL of 20 mM CuCl 2 aqueous solution, 1 mL of 20mM NiCl 2 The aqueous solution is added into the beaker of the sample in step (2), and the fully dispersed CeO-containing 2 Add ethanolamine to the above beaker, stir for 24 h until the solution is blue and transparent, pipette 600 µL (40%) formaldehyde solution, slowly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com