Regenerated silk fiber with salt solution as coagulating bath and method for preparing same

A technology of regenerated silk and coagulation bath, applied in the fields of textile fiber, protein chemistry, material science, and bionics, it can solve problems such as pure silk protein aqueous solution that has not yet been seen, achieve excellent mechanical properties, avoid pollution and harm, and control degradation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

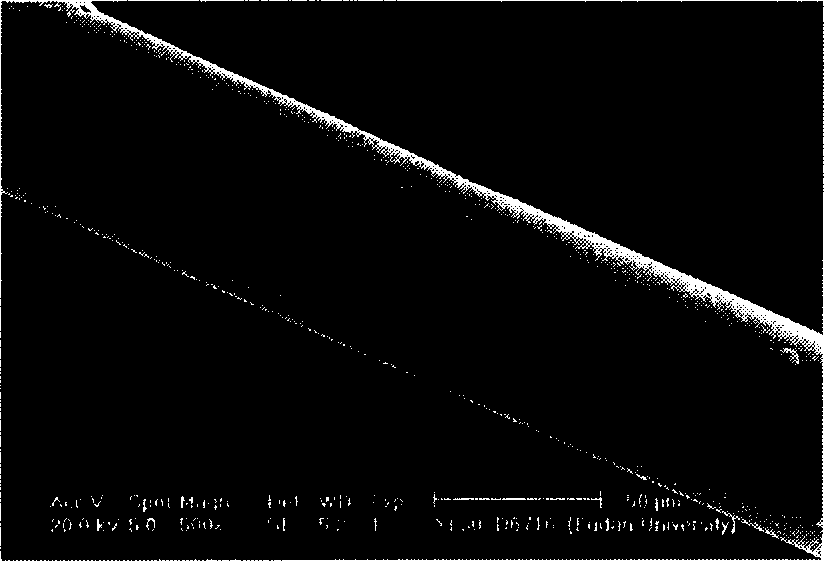

Image

Examples

Embodiment 1

[0018] Example 1: Using 13% regenerated silk protein aqueous solution as the spinning dope, 40% (NH 4 ) 2 SO 4 The solution is used as a coagulation bath for wet spinning, and the spinning temperature is 25°C. The obtained regenerated silk fiber has a residence time of 8 minutes in the coagulation bath and is stretched to 4 times the original length, washed with water and dried. Then, it was stretched for 1 time in hot water at 90°C, and then dried by steam treatment at 120°C. The obtained regenerated silk fiber had a breaking strength of 0.5 GPa and a breaking elongation of 22%.

Embodiment 2

[0019] Example 2: Using a 20% concentration of regenerated silk protein aqueous solution as the spinning dope, using 20% Na 2 SO 4 The solution (adjust the pH to 4.0) is used as a coagulation bath for wet spinning, and the spinning temperature is 10°C. The obtained regenerated silk fiber has a residence time of 10 minutes in the coagulation bath and is stretched to 5 times the initial length, washed with water and dried. Then, it was stretched 1 times in hot water at 80°C, and then dried by steam treatment at 130°C. The obtained regenerated silk fiber had a breaking strength of 0.4 GPa and a breaking elongation of 20%.

Embodiment 3

[0020] Example 3: Using a 30% concentration of regenerated silk protein aqueous solution as the spinning dope, using saturated Zn 2 SO 4 The solution is used as a coagulation bath for wet spinning, and the spinning temperature is 40°C. The obtained regenerated silk fiber has a residence time of 5 minutes in the coagulation bath, stretched to 4 times the initial length, washed with water, and dried. Then it was stretched for 2 times in hot water at 70°C, and then dried after steam treatment at 110°C. The obtained regenerated silk fiber had a breaking strength of 0.3 GPa and a breaking elongation of 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com