Technique for preparing chicoric acid by using chicory

A technology of cichoric acid and chicory, which is applied in the field of chemical extraction, can solve the problems of increasing the cost of handling and transportation, increasing the weight and volume of cichoric acid products, and achieving the effects of preventing interference, preventing fermentation mildew and degradation, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

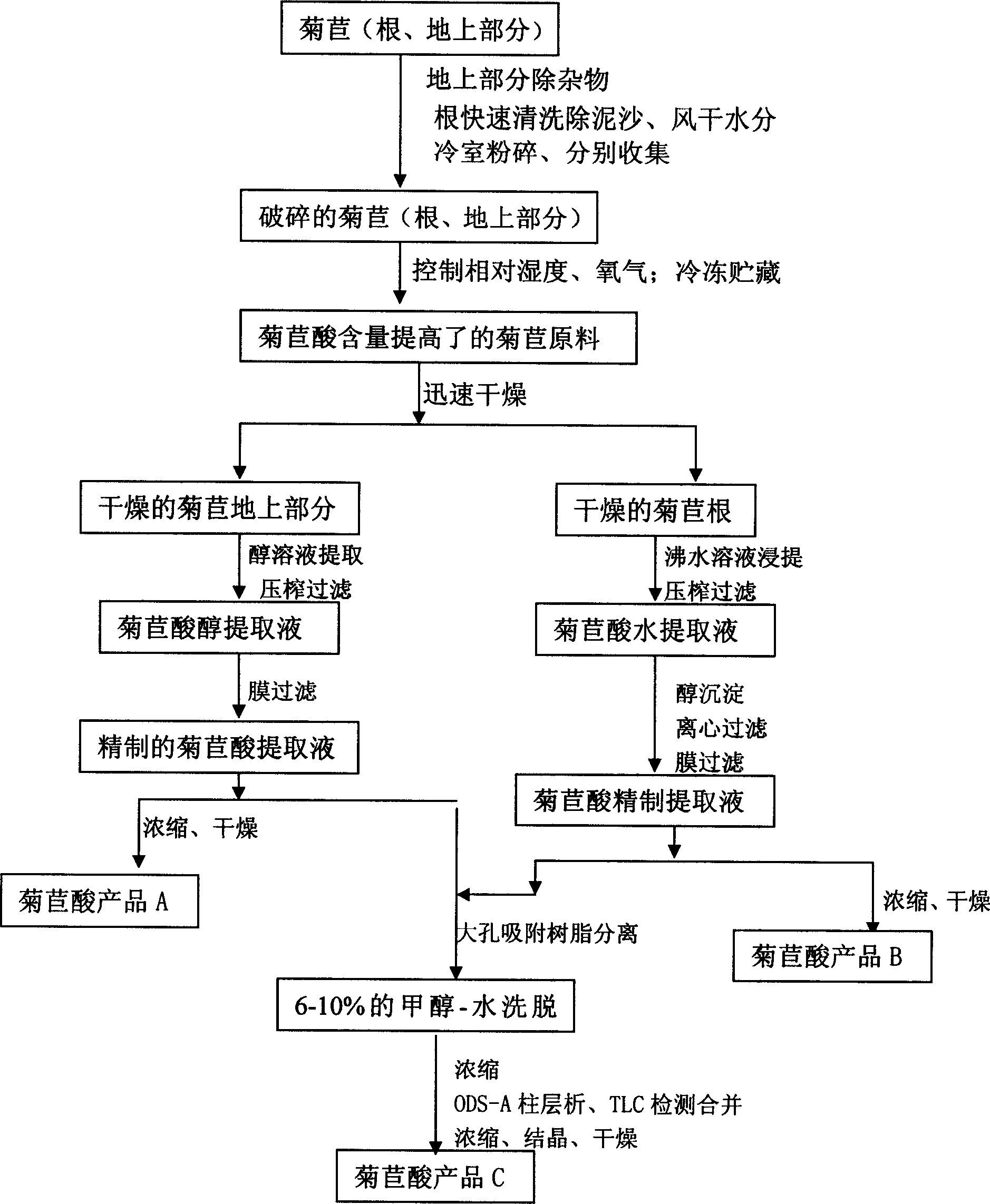

Method used

Image

Examples

preparation example Construction

[0055] 4. Preparation of cichoric acid products:

[0056] 1) Preparation of Chichoric Acid Product A

[0057] The cichoric acid extract obtained from the aerial parts of chicory is filtered through a hollow inorganic fiber microfiltration membrane to remove proteins, tannins, polysaccharides and other large molecular weight interfering components, as well as impurities such as microorganisms, bacteria, and viruses. μm, and then condensed by a rotary thin film evaporator at 40°C, dried at 60°C and a vacuum of 0.08MPa to obtain the finished product of cichoric acid, the humidity of which is less than 8%, preferably less than 5%, the cichoric acid powder has a high content of cichoric acid In 30%, namely cichoric acid product A.

[0058] 2) Preparation of cichoric acid product B:

[0059] ① Refining of root chicory acid extract: concentrate the root chicory acid extract to less than 1 / 2 of the original extract, then add 1-5 times the amount of 95% alcohol (V / V), after adding al...

Embodiment 1

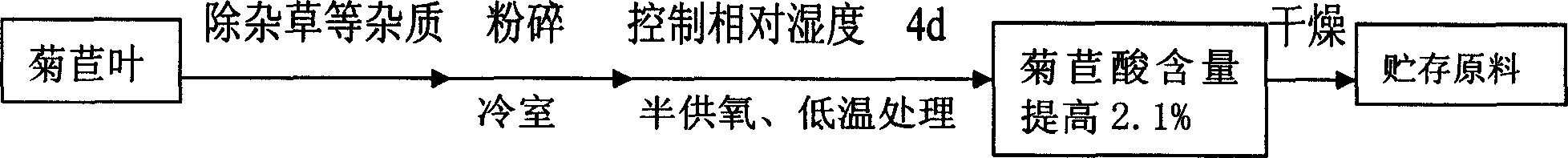

[0066] Embodiment 1: post-harvest treatment of chicory leaves:

[0067] Collect fresh chicory leaves in June, pick out weeds, dead branches and other sundries, quickly crush and cut into 1.5cm segments, the humidity is about 73%, and place 10 kg of crushed leaves in a container with a bulk density of 10 kg within 10 hours. Put it in a polyethylene bag, open it completely, and cut two 2.5cm long incisions on both sides, quickly put it into a cold storage at a temperature of 3°C, keep its relative humidity at 84%, and measure the content of cichoric acid by HPLC after 24 hours of freezing treatment It began to rise and reached the highest value in 96 hours, and its content increased by 1.03% compared with the original. Then the treated chicory leaves were air-dried at 40° C. for 55 hours to obtain dried chicory leaves, which were stored for one year, and the content of chicory acid was determined to be substantially unchanged.

Embodiment 2

[0068] Embodiment 2: Preparation of powdery cichoric acid product A:

[0069] Harvest chicory aerial part (what should be specifically? Stem? Leaf?) in full flowering stage in July, obtain the raw material that cichoric acid content increases to 1.7% through the processing method identical with embodiment 1, get this raw material 100 grams, add 500mL50% ethanol solution, ultrasonically extracted for 40 min, and vacuum filtered to obtain a cichoric acid extract, and the slag was extracted again, and the extracts were combined. Select a microfiltration membrane with a pore size of 0.25 μm to remove impurities to obtain a refined extract of cichoric acid, concentrate it by rotary thin-film evaporation at 40°C, and dry it in vacuum at 60°C to obtain a powdered cichoric acid product A with a moisture content of 6%. The content of cichoric acid was determined by HPLC was 21%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com