Device and method for preparing nanometer tungsten trioxide powder using ultrasonic spray microwave drying method

An ultrasonic spray and microwave drying technology, applied in the direction of tungsten oxide/tungsten hydroxide, etc., can solve the problems of large equipment, large powder loss, low drying efficiency, etc., and achieve the effect of good adaptability, good uniformity, uniform and stable particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

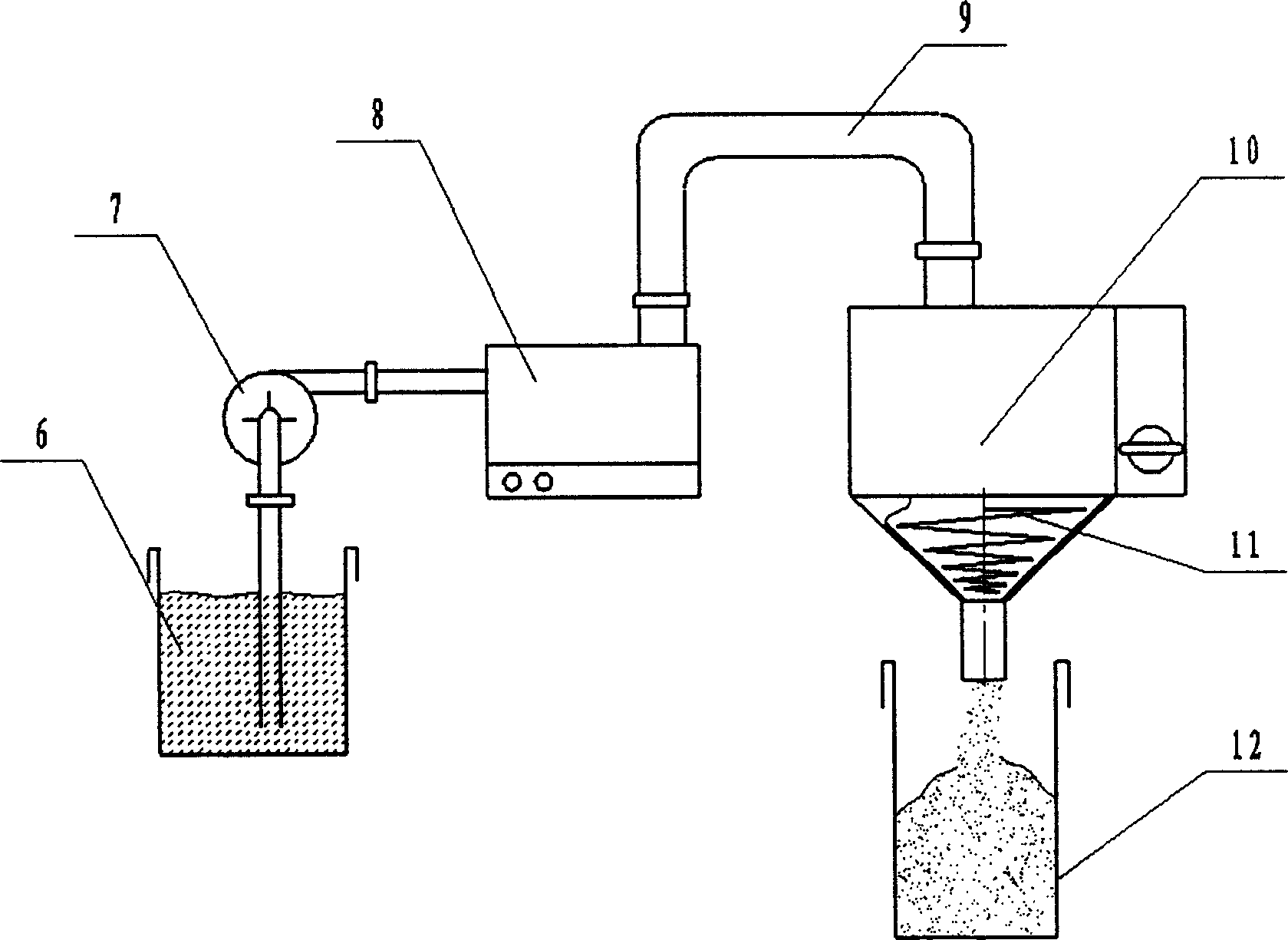

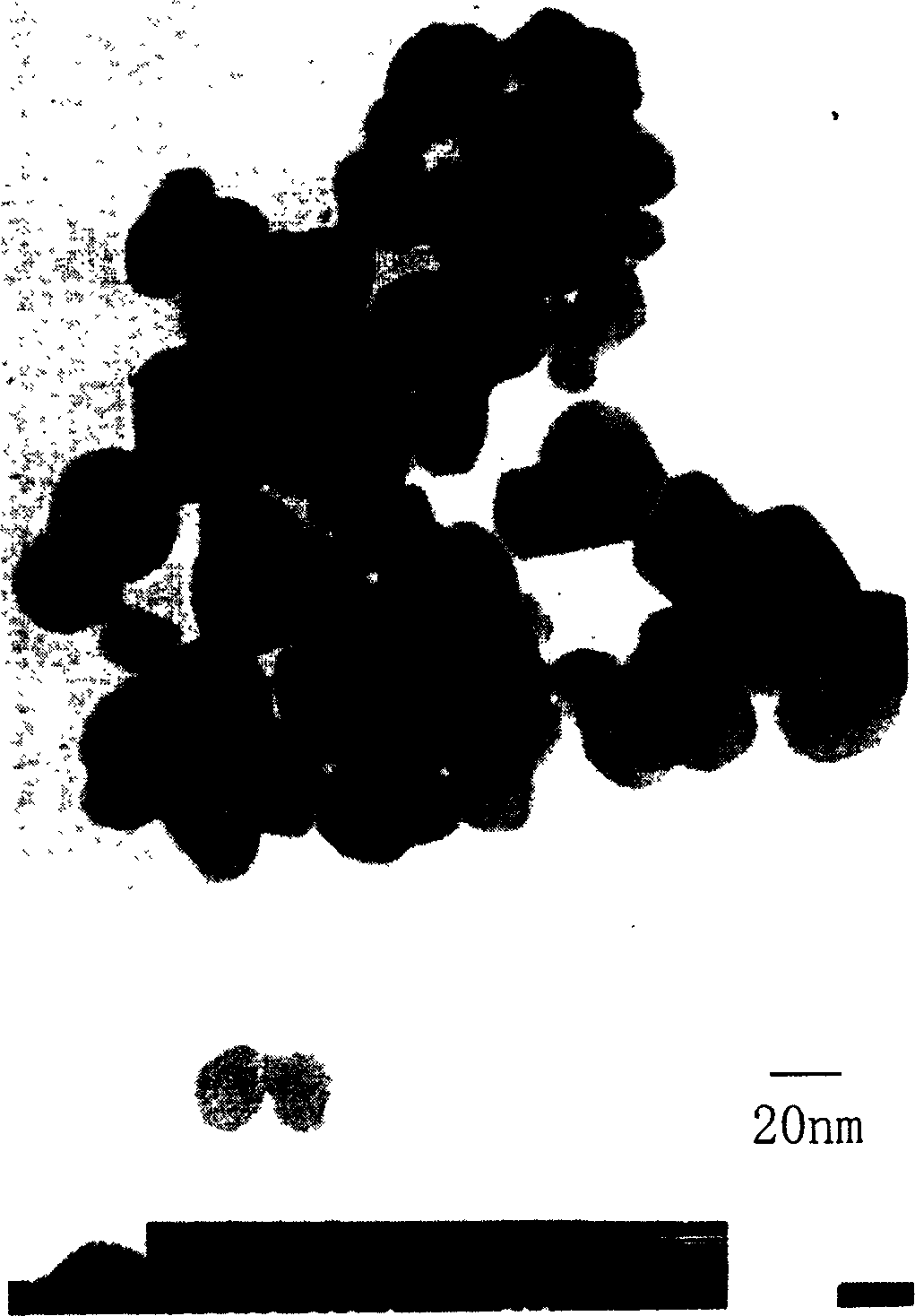

[0024] Under the effect of liquid pump 7, ammonium tungstate solution (tungstate radical content is 150g / liter) is transported in the ultrasonic spray device 8 through pipeline from liquid storage tank 6 with the speed of 10ml / s; Under the ultrasonic wave action of 1700KHz, The ammonium tungstate solution is crushed into mist droplets of about 1 μm; the mist droplets are heated and pre-dried by the conveying pipeline 9 and then transported to the microwave dryer 10. Using 2450MHz continuous microwave, the mist droplets are dried at a rate of 0.8Kg / KW h Speed dehydration, ammonium tungstate undergoes a chemical reaction, decomposes ammonia gas, and at the same time obtains solid particle nano WO 3 , under gravity, the nano-WO 3 The powder gathers at the bottom of the reaction tower, and the nano WO 3 The powder is collected into bucket 12.

Embodiment 2

[0026] Under the action of the liquid pump 7, the ammonium tungstate solution with a tungstate concentration of 550g / liter is transported from the liquid storage tank 6 to the ultrasonic spray device 8 through a pipeline at a speed of 25ml / s; under the action of ultrasonic waves with a frequency of 3600KHz, The ammonium tungstate solution is crushed into mist droplets of about 0.3 μm; the mist droplets are transported to a microwave dryer, and the mist droplets are dehydrated at a drying speed of 1Kg / KW h by using a 915MHz continuous microwave, and the ammonium tungstate is heated to produce chemical Reaction, ammonia gas is decomposed, and solid particle nano WO is obtained at the same time 3 , the powder is deposited at the bottom of the reaction chamber, and the nano-WO 3 The powder is collected into bucket 12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com