Inverter device

一种逆变器、控制器的技术,应用在逆变器装置领域,能够解决二次电流困难等问题,达到减轻负荷、抑制温度上升、扩大阀开度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

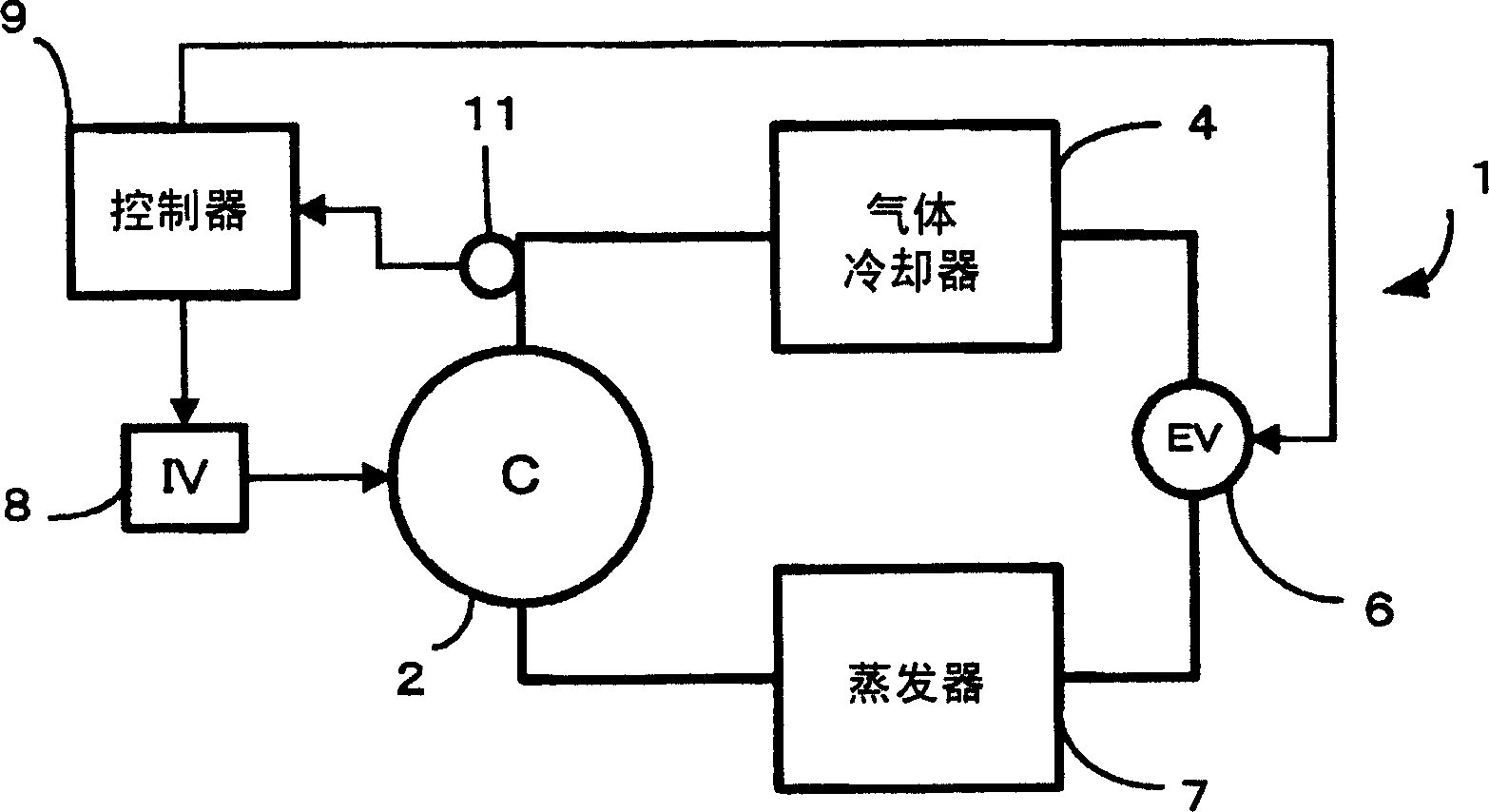

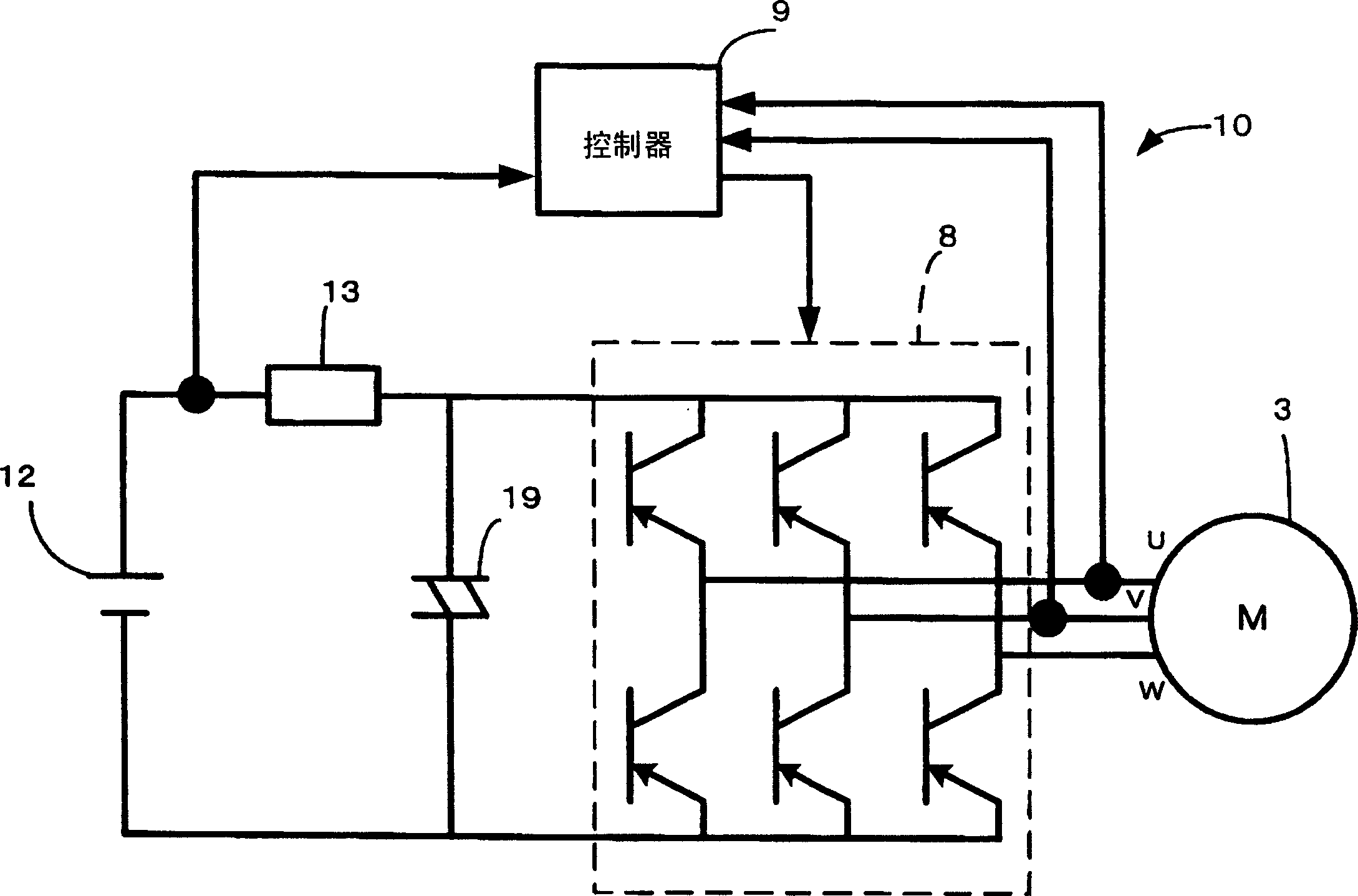

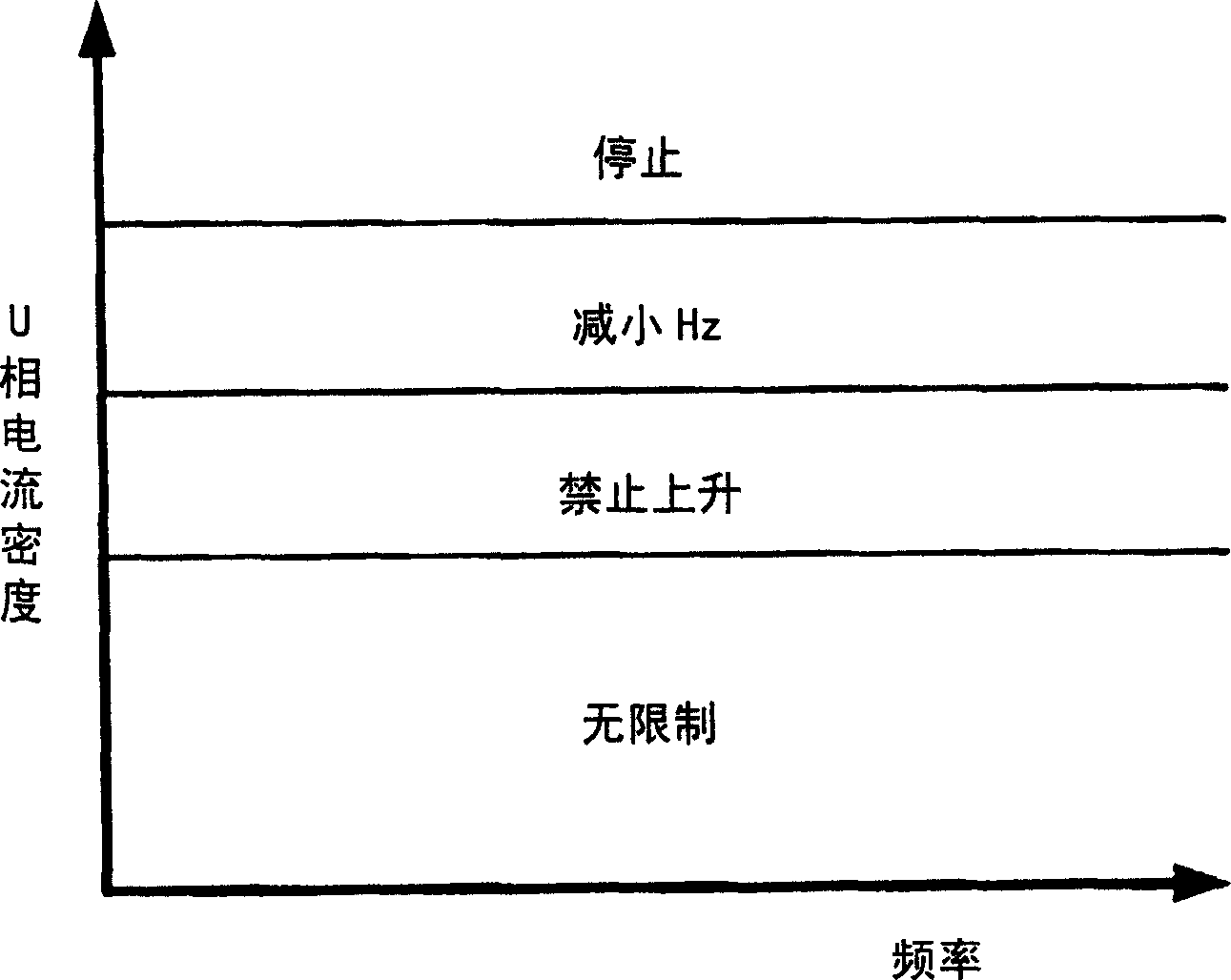

[0037] The controller 9 calculates the U-phase current density (divided by the current value by the coil cross-sectional area) flowing through the coil of the motor 3 from the secondary current (Iu) used for vector control. Next, when the U-phase current density is equal to or less than a predetermined first upper limit, the electric motor 3 is operated at a required frequency determined by the vehicle interior temperature and the set temperature (no limitation). Next, when the U-phase current density rises from the first upper limit value, the operation frequency of the electric motor 3 is restricted from being raised regardless of the required frequency.

[0038] Then, when the U-phase current density rises higher than the second upper limit higher than the first upper limit, the operating frequency of the motor 3 is lowered lower than the current frequency regardless of the required frequency. Then, finally, the motor 3 is stopped when the current density rises to a third u...

Embodiment 2

[0042] Next, another embodiment of the protection operation performed by the controller 9 will be described. Also in this case, the controller 9 calculates the U-phase current density flowing through the coil of the motor 3 from the secondary current (Iu) for vector control. Next, when the U-phase current density is equal to or less than a predetermined upper limit, the valve opening of the expansion valve 6 is adjusted to a value determined by the interior temperature, the set temperature, and the temperature of each part in the coolant circuit. Required expansion valve opening.

[0043] Next, when the U-phase current density increases from the first upper limit value, the valve opening of the expansion valve 6 is expanded in predetermined steps regardless of the expansion valve opening. In this way, the controller 9 calculates the current density flowing through the coil of the motor 3 from the secondary current flowing through the motor 3. When the current density rises, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com