Spinning wheel type automatic scutcher

A technology of hemp making machine and spinning machine, which is applied in mechanical processing, textile and papermaking, fiber mechanical separation, etc. It can solve the problems of uneconomical, poor randomness, and large damage to hemp fibers, and achieves high degree of automation, stable performance, and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

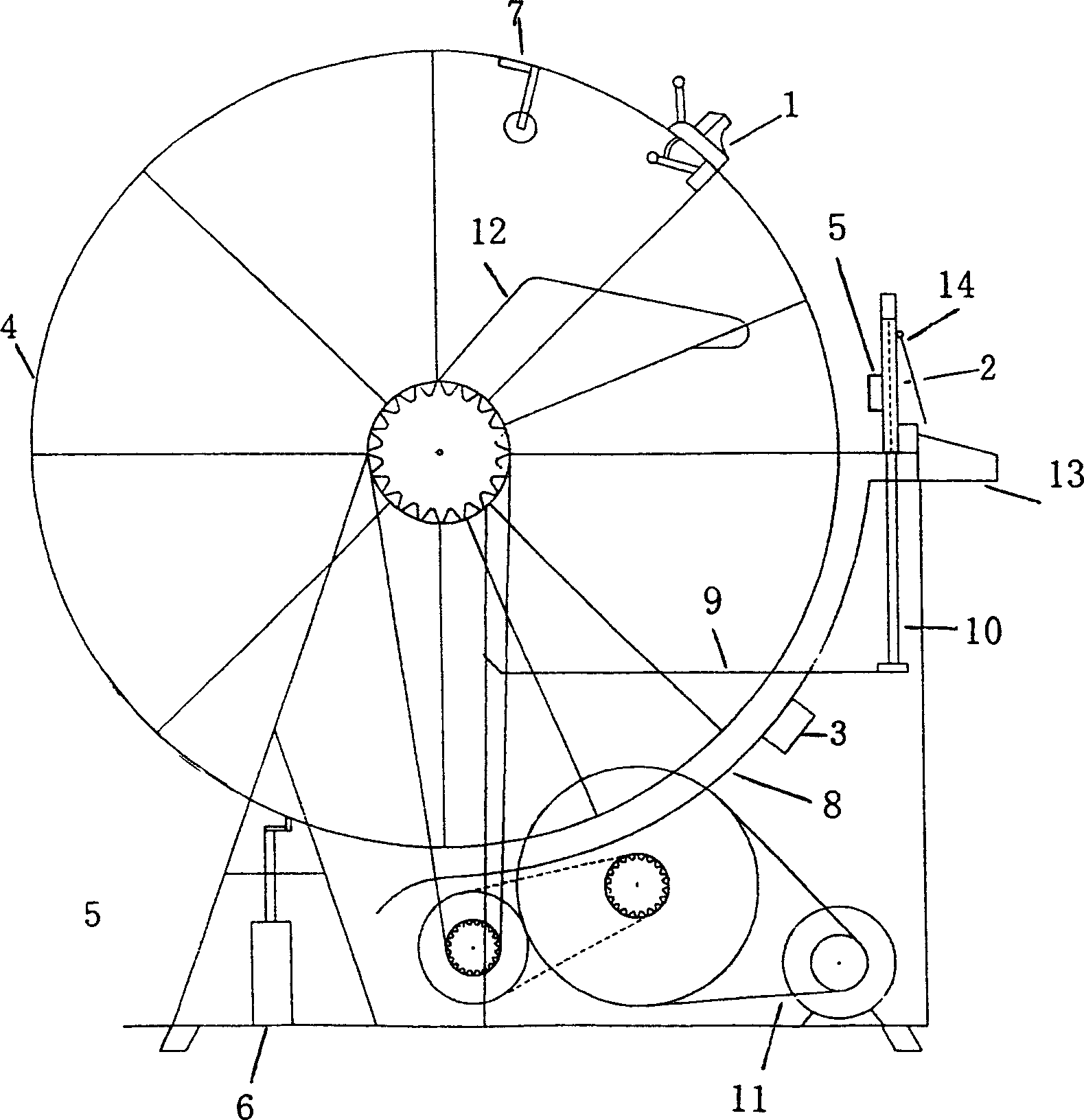

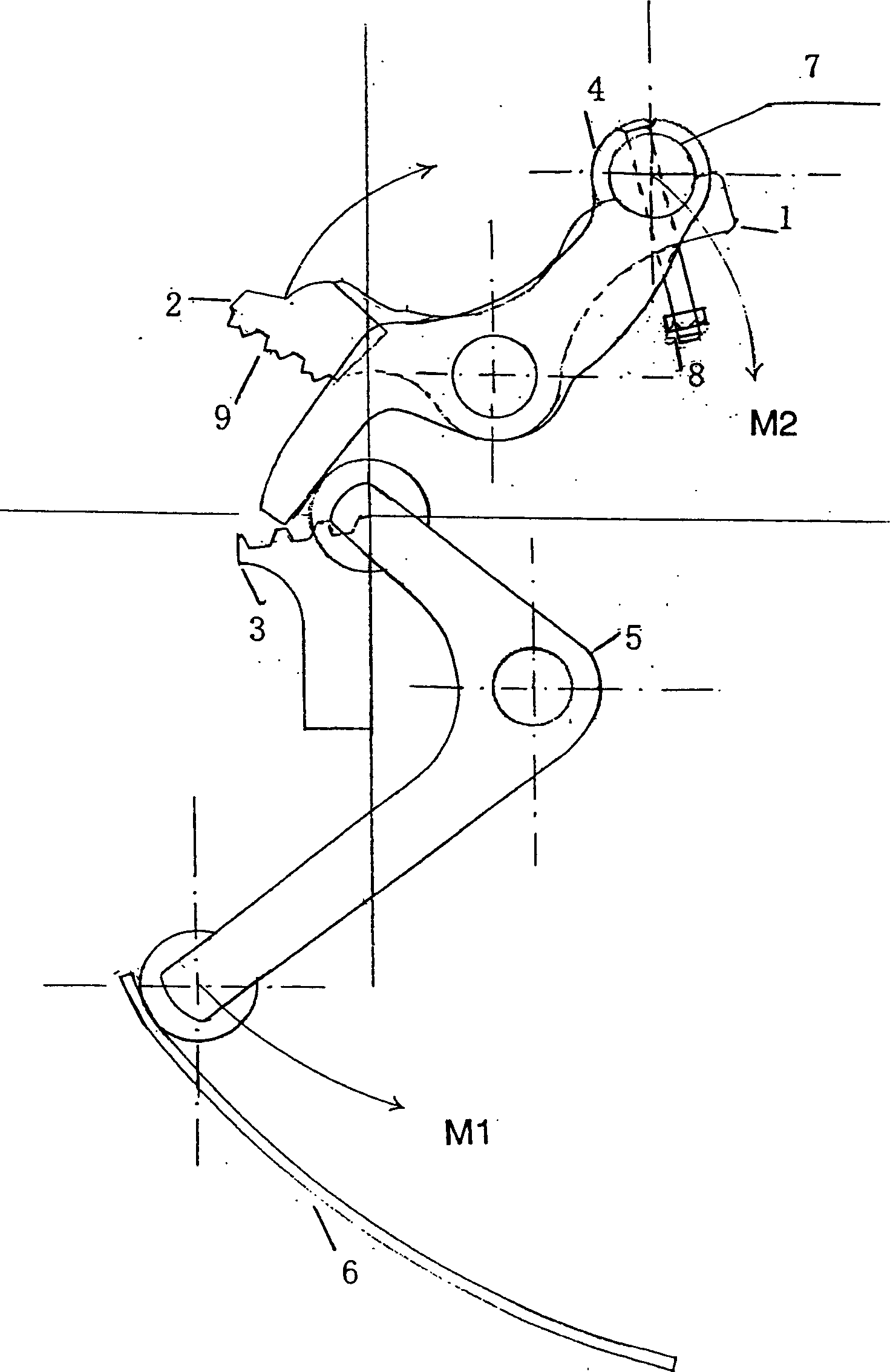

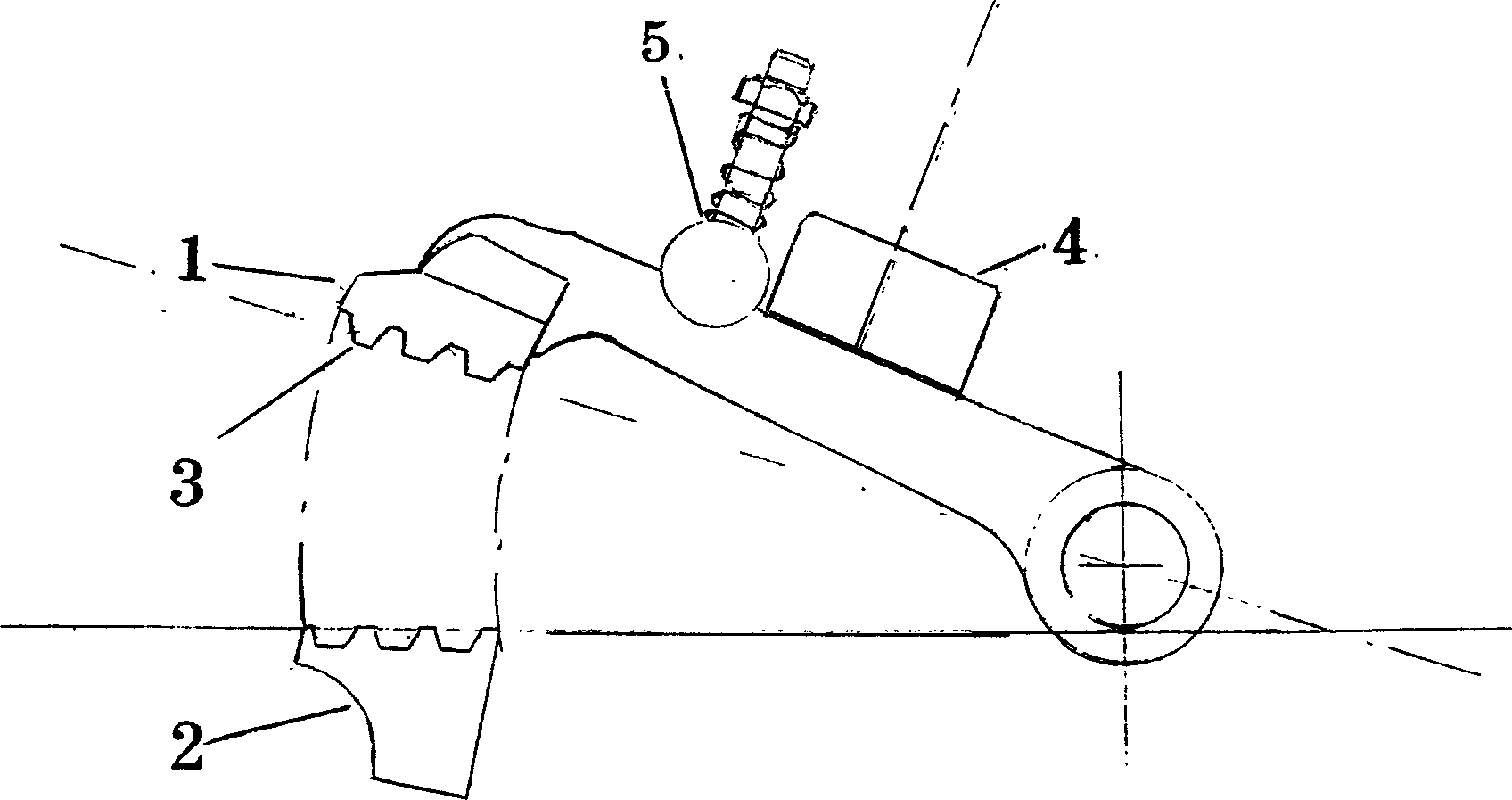

[0024] figure 1 As shown, the automatic spinning machine is composed of a spinning car body 4, a crocodile-type dog-tooth-type adjustable self-locking fixture 1, a pressure-stripping cutter 2, a guide rail bumper, an electrical appliance, an automatic control and an electromagnetic brake control mechanism 3, 5, 6, 8, 12, hemp throwing plate mechanism 7, power and transmission device 11, cutter body starting arm 9 and tappet 10, feeding table 13, cutter body touch bar 14 are combined to form. The spinning wheel body 4 serves as a unified carrier, and the crocodile dog-tooth adjustable self-locking fixture 1 is radially screwed on the spinning wheel edge holder, and the pressure stripping tool 2 is horizontally screwed on the front feeding platform of the frame The ends are parallel to the clamps, the guide rail bumps 8 and 12 are respectively fixed on the spokes of the spinning wheel, the hemp throwing mechanism 7 is fixed behind 1 in parallel, and the tappet 10 is supported b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com