Process for extracting starfish steroid glycoside from starfish

A technology of steroidal saponins and starfish, which is applied in the field of extracting starfish steroidal saponins, can solve the problems of unsuitable extraction of large polar or macromolecular substances, unsatisfactory extraction effect, low dielectric constant, etc., and achieve good selectivity, The effect of shortening the processing time and maintaining biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

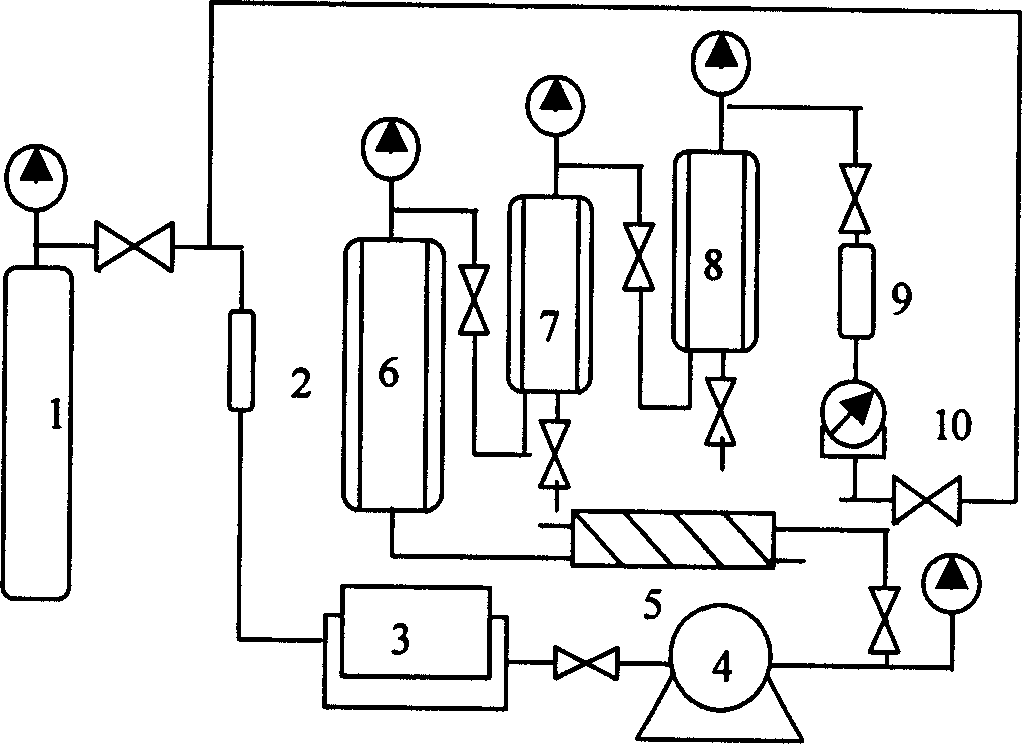

Method used

Image

Examples

Embodiment 1

[0024] Weigh 200g starfish dry powder into the extraction tank, use CO 2 As a supercritical fluid, the extraction pressure is 25MPa, and the extraction temperature is 323K. One-stage separation is adopted, the pressure of the separation column is 5MPa, the temperature of the separation column is 333K, and the extraction time is 3h. The extract was discharged from the separator, weighed, and the yield of total extract was calculated. The content of starfish saponin in the extract was determined by ultraviolet-visible spectrophotometry, and the yield was calculated. It is determined that the yield of the total extract is 1.98%, and starfish saponin is basically not extracted.

[0025] This example illustrates pure supercritical CO 2 Only the fat-soluble part of starfish can be extracted, but not the more polar saponins.

Embodiment 2

[0027] Weigh 200g starfish dry powder and put it into the extraction tank, and degrease according to the method of implementation case 1. The extraction temperature was 323K, the pressure was 25MPa, methanol and 95% ethanol were used as co-solvents respectively, 200mL of co-solvent was added first, static extraction was carried out for 0.5h, 100mL of co-solvent was added by pump after 1h, and 100mL of co-solvent was added by pump after 1h. All the other conditions and methods are the same as in Example 1. The extraction results are shown in Table 1.

[0028] Table 1 Effects of different types of cosolvents on the extraction of starfish saponins

[0029] Total Extract Yield Starfish Saponin Yield Starfish in Total Extract

[0030] Co-solvent type

[0031] (%) (%) Saponin content

[0032] Ethanol 2.18 0.59 27.06

[0033] Methanol 2.25 0.62 27.56

[0034] The purpose of degreasing according to Example 1 is to reduce the interference of...

Embodiment 3

[0036] Weigh 200g starfish dry powder and put it into the extraction tank, and degrease according to the method of implementation case 1. Prepare 0.01mol / L surfactant-ethanol solution of AOT, TX-10, CTBA, Span, AGP, Tween as a co-solvent, add 200mL to the extractor, and extract statically for 3h at a temperature of 323K and a pressure of 25MPa, according to the implementation The method of example 1 calculates the yield of total extract, starfish saponin, and the content of starfish saponin in the extract, and the results are shown in Table 2.

[0037] Table 2 Effects of different types of surfactants on the extraction of starfish saponins

[0038] Total Extract Yield Starfish Saponin Yield Starfish Saponin in Total Extract

[0039] Surfactant

[0040] (%) (%) Glycoside content (%)

[0041] None 1.06 0.25 23.58

[0042] AOT 1.32 0.36 27.27

[0043] TX-10 1.25 0.31 24.80

[0044] CTBA 1.22 0.29 23.77

[0045] Span 1.09 0.25 22.94

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com