Hollow polymer microsphere and method for preparing same

A polymer and polymer layer technology, applied in the field of polymer hollow microspheres and its preparation, can solve the problems of practical application limitations, thermal stability and chemical stability to be improved, and achieve high chemical stability and broad application prospects and the effect of using value and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

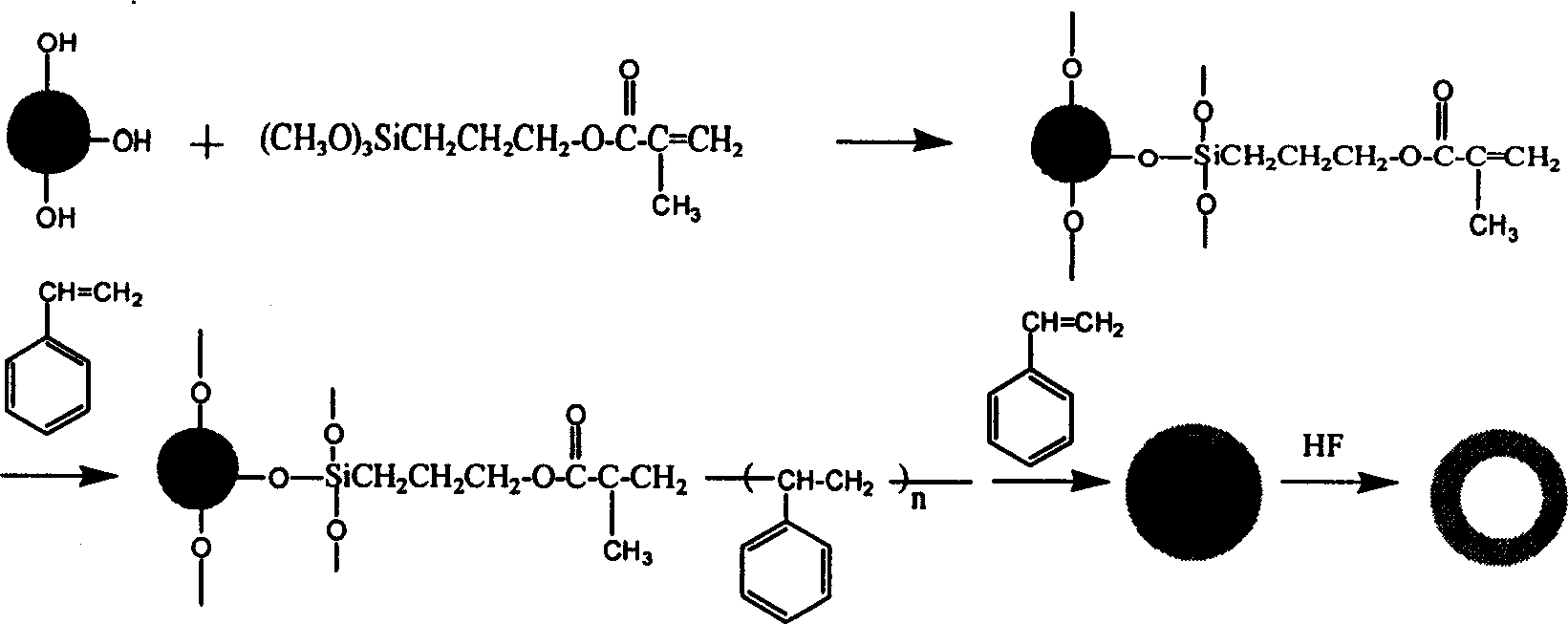

Method used

Image

Examples

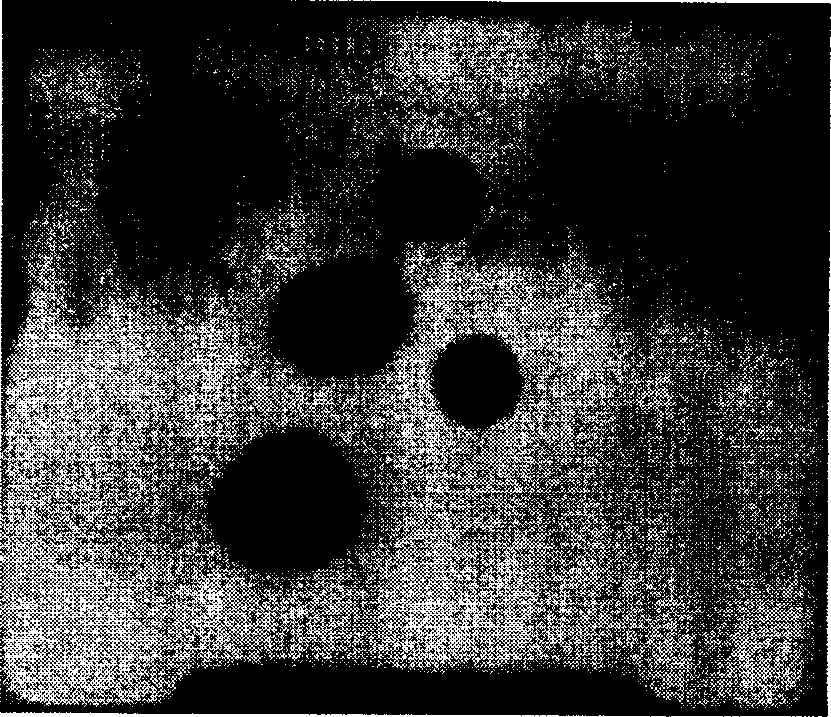

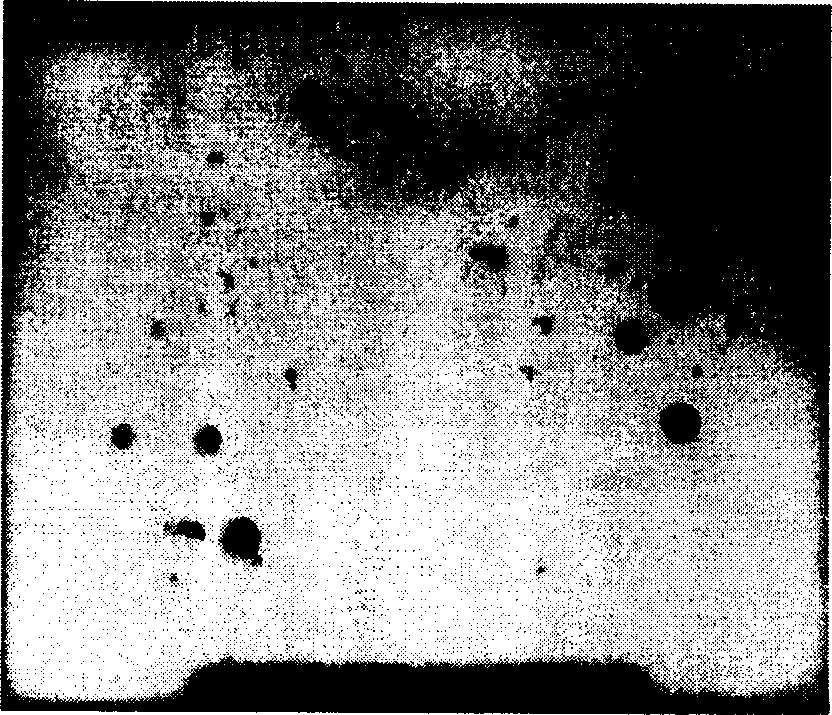

Embodiment 1

[0031] Add 20ml of ethyl orthosilicate, 250ml of absolute ethanol and 10ml of ammonia water into a three-necked flask equipped with a reflux condensing device and a stirrer, stir in a water bath at 25°C for 24 hours, and then slowly evaporate to remove part of the ethanol to obtain SiO 2 Alcoholic solution of nanoparticles. Accurately weigh 8ml of the alcohol solution of silica nanoparticles (concentration: 0.025g / ml), and add dropwise 20ml of the ethanol solution of KH-570 silane coupling agent (concentration: 0.025g / ml). Then react in a water bath at 35°C for 36 hours, and dry in vacuum at 35°C overnight to obtain the purified SiO treated with the coupling agent. 2 Nano powder. In a three-necked flask equipped with a reflux condensing device, 1.2 g of the above-mentioned coupling agent-treated SiO 2Ultrasonic dispersion of nano powder in 10ml of absolute ethanol, while adding 0.24g of sodium bicarbonate, 0.18g of sodium lauryl sulfate and 100ml of deionized water, after u...

Embodiment 2

[0034] Same as Example 1, but the concentration of KH-570 was changed to 0.05 g / ml, and the amount of styrene monomer was changed to 15 ml.

Embodiment 3

[0036] Same as Example 1, but the concentration of KH-570 was changed to 0.1 g / ml, and the amount of styrene monomer was changed to 30 ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com