Method of modifying solid surface and product obtained

A solid substance and surface modification technology, which is applied to the device for coating liquid on the surface, special surface, pretreatment surface, etc., can solve the problem of insufficient modification, difficulty in uniform treatment of solid substance by flame, and long-term effect and other issues to achieve the effect of reducing residual components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0054] In the first embodiment, a gaseous substance containing a modifier compound having at least a silane atom, a titanium atom, or an aluminum atom is sprayed on a solid substance by a heat source at a temperature of 400° C. or higher (the first surface modification method), Or the method of surface modification of a solid substance heated to a temperature of 400° C. or higher by a heat source after spraying a gaseous substance containing a modifier compound having at least silane atoms, titanium atoms or aluminum atoms on the solid substance ( 2nd surface modification method).

[0055] 1. Solid matter

[0056] The solid material used in the first embodiment is typically silicone rubber or fluororubber, and will be described in detail in the second embodiment.

[0057] 2. Gas-like substance

[0058] (1) modifier compound

[0059] ①Boiling point

[0060] The boiling point (atmospheric pressure) of the modifier compound is preferably a value in the range of 10 to 200°C. ...

no. 2 Embodiment approach

[0154] The second embodiment is: a gaseous substance containing a modifier compound having at least a silane atom, a titanium atom or an aluminum atom is sprayed on a solid substance by a heat source at a temperature of 400° C. or higher, thereby making the wettability index Surface-modified solid matter (first solid matter) with a value in the range of 40 to 80 dyn / cm (measurement temperature 25°C), or a compound containing a modifier compound having at least a silane atom, a titanium atom, or an aluminum atom A surface-modified solid whose wettability index (measurement temperature 25°C) is in the range of 40 to 80 dyn / cm after the gaseous substance is sprayed on the solid substance and heated to a temperature of 400°C or higher by a heat source Substance (second solid substance).

[0155] 1. Solid matter

[0156] (1) Rubber

[0157] In addition, when constituting the surface-modified solid substance, the solid substance is selected from silicone rubber, fluororubber, natu...

Embodiment 1

[0204] 1. Surface modification of solid substances

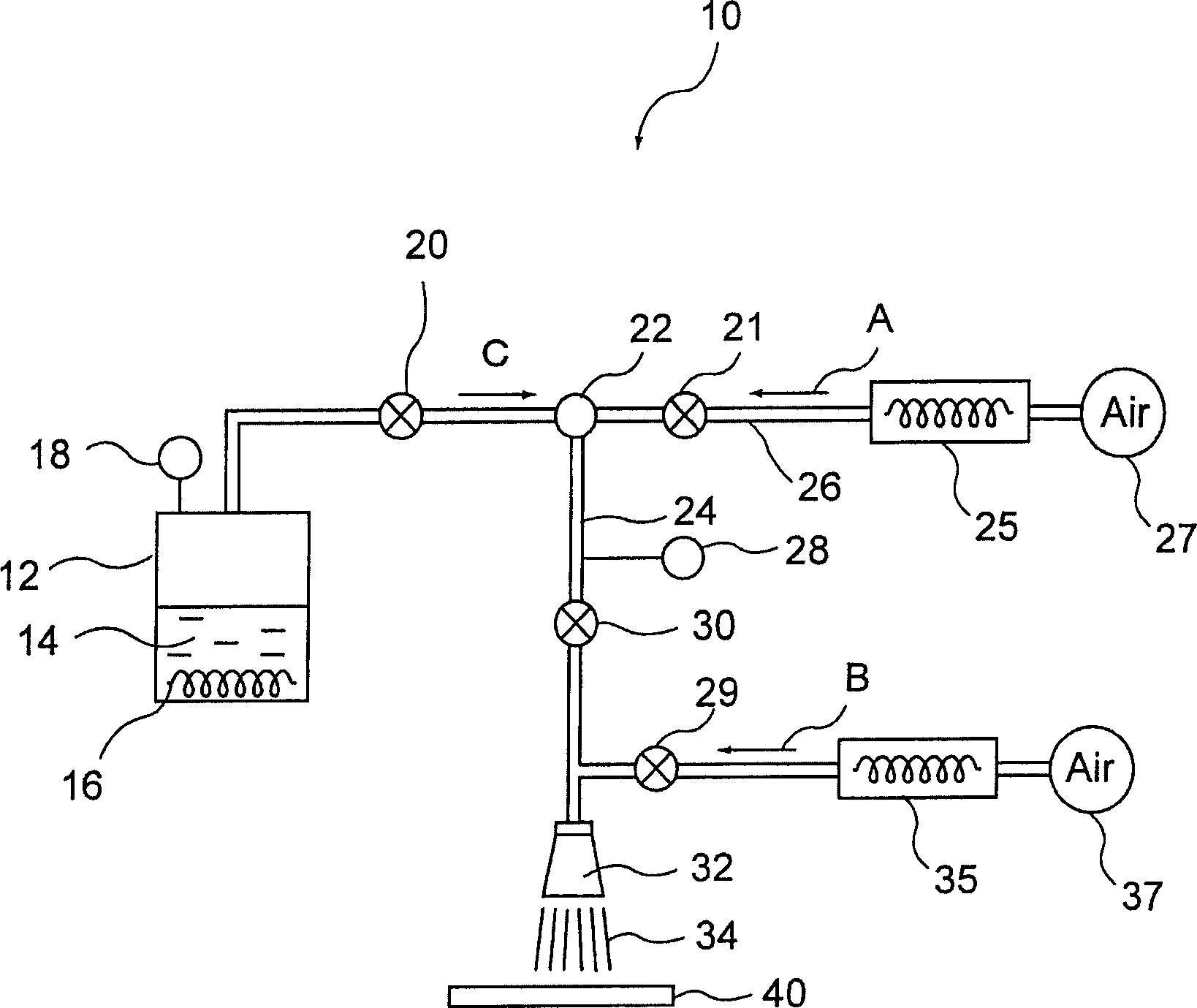

[0205] Prepare a sheet (area 100cm) made of silicone rubber (hardness: 80) with a thickness of 2mm 2 ). Next, use figure 1 In the surface modifying device shown, the surface treatment of the silicone rubber sheet was performed for 0.5 seconds by heating with a ceramic heater so that the temperature of the gaseous substance containing the modifying agent compound reached 700°C.

[0206] As the gaseous substance containing the modifying agent compound, 0.0001 mol % of tetramethylsilane with a boiling point of 27° C., 0.00001 mol % of tetramethoxysilane with a boiling point of 122° C., and a cylinder filled with compressed air ( cartridge) mixture.

[0207] 2. Evaluation of solid matter

[0208] (1) Wetting index

[0209] The wettability index of the surface-modified silicone rubber sheet was measured with a standard solution. In addition, the wetting index of the silicone rubber sheet before surface modification was also...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com